The waste concrete crushing production line can efficiently recycle and reuse waste concrete through crushing, screening and other processes, reduce pollution and save resources. The production line is scientifically configured, environmentally friendl

The waste concrete crushing production line can efficiently recycle and reuse waste concrete through crushing, screening and other processes, reduce pollution and save resources. The production line is scientifically configured, environmentally friendly and efficient. It can be selected as fixed or mobile according to needs, and has broad application prospects.

With the acceleration of urbanization, a large amount of waste concrete generated by building demolition has become an environmental problem that needs to be solved urgently. How to effectively recycle these waste concretes, reduce environmental pollution and realize resource reuse has become the focus of attention in the industry. The emergence of the waste concrete crushing production line provides a perfect solution to this problem. The following is a detailed introduction to the workflow and advantages of this waste concrete crushing production line.

Waste concrete crushing production line equipment

The workflow of the waste concrete crushing production line

The overall process of the waste concrete crushing production line is similar to other stone crushing production lines. First, the waste concrete is transported to the processing plant by truck. Then, pretreatment is carried out, including using a hydraulic hammer to reduce oversized blocks and manually cutting off overlong steel bars to prevent damage to the conveyor belt. After pretreatment, the material enters the jaw crusher for primary crushing, and the discharge port is set to 100mm. After that, the impact crusher is used for secondary crushing to further process the material into a particle size of 50mm.

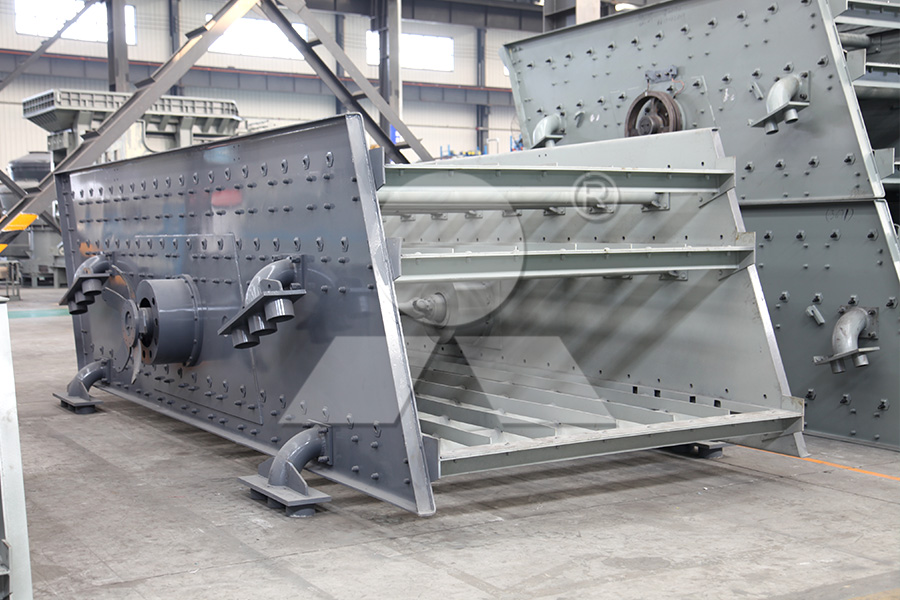

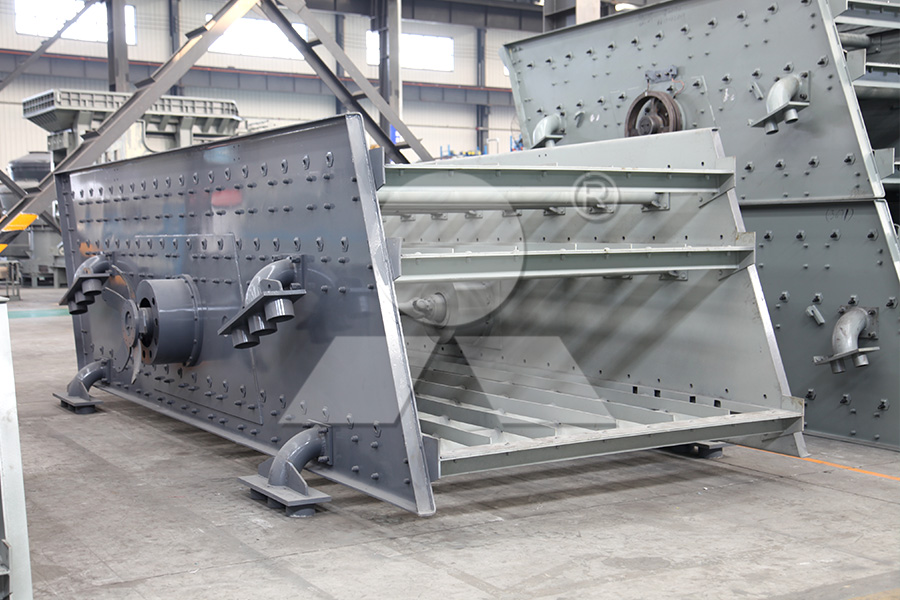

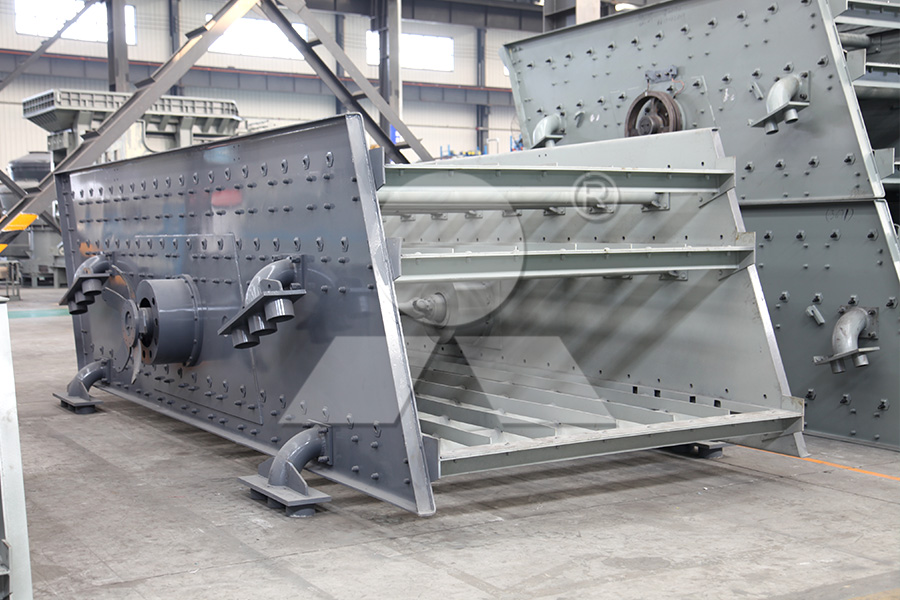

During the crushing process, the jaw crusher can easily crush the concrete with steel bars and separate the steel bars. The steel bars are further removed by the iron remover. Then, the production line screens the finished material into two specifications of 0-5mm and 5-50mm through a vibrating screen. The entire production process is stable and effective, ensuring high-quality sand and gravel aggregate production.

Efficient and energy-saving process and equipment

The waste concrete crushing production line adopts scientific equipment configuration to ensure the maximum crushing efficiency and resource utilization. The separation of waste steel bars by iron removers greatly improves the quality of the finished material. The wear rate of each device is low, which reduces the failure rate and reduces the production cost. The equipment has a compact structure and occupies a small area, which is very suitable for installation and use in various venues.

The main equipment includes:

Vibrating feeder: evenly and quantitatively feeds waste concrete into the crusher to avoid blockage caused by uneven feeding.

Jaw crusher: used for coarse crushing, can effectively handle waste concrete with high hardness.

Cone crusher: used for medium and fine crushing, adopts the principle of laminated crushing, and the finished material has uniform particle size.

Sand washing machine: washes the finely crushed concrete particles, removes surface impurities, and improves the quality of the finished product.

Vibrating screen and conveyor: used for screening and conveying to ensure the smooth flow of materials in all links.

Double guarantee of environmental protection and economic benefits

The recycling and reuse of waste concrete can not only save a lot of resources, but also bring considerable economic benefits to enterprises. After crushing, washing and other processes, waste concrete can be used to produce environmentally friendly building materials such as lawn bricks, permeable bricks, and insulation bricks, and can even be used as cement raw materials to promote the green development of the construction industry.

In addition, enterprises using this production line can enjoy the government's environmental protection tax support, reduce landfill costs, and avoid a large amount of waste pollution to the environment. The production line is equipped with an efficient dust removal system and noise prevention facilities to ensure that the production process meets environmental protection standards, and the dust removal rate is as high as 99% or more.

Choice between fixed and mobile production lines

According to the specific needs of customers, there are two working modes for waste concrete crushing production lines: fixed production line and mobile crushing station. Both modes can effectively crush waste concrete into useful sand and gravel aggregates, but mobile crushing stations have higher flexibility. It can not only be transferred at any time to reduce transportation costs, but also operate flexibly at different construction sites, suitable for the complex environment of demolition sites.

The crushing, recycling and reuse of waste concrete not only helps to alleviate the problem of construction waste accumulation, but also provides sufficient raw materials for the production of environmentally friendly building materials. With the increasingly stringent environmental protection policies and the increasing demand for resource conservation, the market demand for waste concrete crushing production lines will continue to grow, and it has broad application prospects.

By using waste concrete crushing production lines, enterprises can not only provide efficient and environmentally friendly solutions for urban construction waste treatment, but also achieve a win-win situation of economic and environmental benefits while reducing costs and improving resource utilization.

Previous: SMP Crusher

Next: SMP Crusher

The waste concrete crushing production line can efficiently recycle and reuse waste concrete through crushing, screening and other processes, reduce pollution and save resources. The production line is scientifically configured, environmentally friendl

The waste concrete crushing production line can efficiently recycle and reuse waste concrete through crushing, screening and other processes, reduce pollution and save resources. The production line is scientifically configured, environmentally friendly and efficient. It can be selected as fixed or mobile according to needs, and has broad application prospects.

With the acceleration of urbanization, a large amount of waste concrete generated by building demolition has become an environmental problem that needs to be solved urgently. How to effectively recycle these waste concretes, reduce environmental pollution and realize resource reuse has become the focus of attention in the industry. The emergence of the waste concrete crushing production line provides a perfect solution to this problem. The following is a detailed introduction to the workflow and advantages of this waste concrete crushing production line.

Waste concrete crushing production line equipment

The workflow of the waste concrete crushing production line

The overall process of the waste concrete crushing production line is similar to other stone crushing production lines. First, the waste concrete is transported to the processing plant by truck. Then, pretreatment is carried out, including using a hydraulic hammer to reduce oversized blocks and manually cutting off overlong steel bars to prevent damage to the conveyor belt. After pretreatment, the material enters the jaw crusher for primary crushing, and the discharge port is set to 100mm. After that, the impact crusher is used for secondary crushing to further process the material into a particle size of 50mm.

During the crushing process, the jaw crusher can easily crush the concrete with steel bars and separate the steel bars. The steel bars are further removed by the iron remover. Then, the production line screens the finished material into two specifications of 0-5mm and 5-50mm through a vibrating screen. The entire production process is stable and effective, ensuring high-quality sand and gravel aggregate production.

Efficient and energy-saving process and equipment

The waste concrete crushing production line adopts scientific equipment configuration to ensure the maximum crushing efficiency and resource utilization. The separation of waste steel bars by iron removers greatly improves the quality of the finished material. The wear rate of each device is low, which reduces the failure rate and reduces the production cost. The equipment has a compact structure and occupies a small area, which is very suitable for installation and use in various venues.

The main equipment includes:

Vibrating feeder: evenly and quantitatively feeds waste concrete into the crusher to avoid blockage caused by uneven feeding.

Jaw crusher: used for coarse crushing, can effectively handle waste concrete with high hardness.

Cone crusher: used for medium and fine crushing, adopts the principle of laminated crushing, and the finished material has uniform particle size.

Sand washing machine: washes the finely crushed concrete particles, removes surface impurities, and improves the quality of the finished product.

Vibrating screen and conveyor: used for screening and conveying to ensure the smooth flow of materials in all links.

Double guarantee of environmental protection and economic benefits

The recycling and reuse of waste concrete can not only save a lot of resources, but also bring considerable economic benefits to enterprises. After crushing, washing and other processes, waste concrete can be used to produce environmentally friendly building materials such as lawn bricks, permeable bricks, and insulation bricks, and can even be used as cement raw materials to promote the green development of the construction industry.

In addition, enterprises using this production line can enjoy the government's environmental protection tax support, reduce landfill costs, and avoid a large amount of waste pollution to the environment. The production line is equipped with an efficient dust removal system and noise prevention facilities to ensure that the production process meets environmental protection standards, and the dust removal rate is as high as 99% or more.

Choice between fixed and mobile production lines

According to the specific needs of customers, there are two working modes for waste concrete crushing production lines: fixed production line and mobile crushing station. Both modes can effectively crush waste concrete into useful sand and gravel aggregates, but mobile crushing stations have higher flexibility. It can not only be transferred at any time to reduce transportation costs, but also operate flexibly at different construction sites, suitable for the complex environment of demolition sites.

The crushing, recycling and reuse of waste concrete not only helps to alleviate the problem of construction waste accumulation, but also provides sufficient raw materials for the production of environmentally friendly building materials. With the increasingly stringent environmental protection policies and the increasing demand for resource conservation, the market demand for waste concrete crushing production lines will continue to grow, and it has broad application prospects.

By using waste concrete crushing production lines, enterprises can not only provide efficient and environmentally friendly solutions for urban construction waste treatment, but also achieve a win-win situation of economic and environmental benefits while reducing costs and improving resource utilization.

Previous: SMP Crusher

Next: SMP Crusher

500 tons per hour sand making machine price

500 tons per hour sand making machine price How to choose equipment for crushing and reusing old cement pavement

How to choose equipment for crushing and reusing old cement pavement How to configure railway ballast stone crushing and processing equipment

How to configure railway ballast stone crushing and processing equipment Sand and gravel crusher equipment manufacturer - Shibang Group full life cycle service

Sand and gravel crusher equipment manufacturer - Shibang Group full life cycle service How to maintain the mobile sand making and crushing machine on a daily basis

How to maintain the mobile sand making and crushing machine on a daily basis 500 tons per hour sand making machine price

500 tons per hour sand making machine price How to choose equipment for crushing and reusing old cement pavement

How to choose equipment for crushing and reusing old cement pavement How to configure railway ballast stone crushing and processing equipment

How to configure railway ballast stone crushing and processing equipment Sand and gravel crusher equipment manufacturer - Shibang Group full life cycle service

Sand and gravel crusher equipment manufacturer - Shibang Group full life cycle service How to maintain the mobile sand making and crushing machine on a daily basis

How to maintain the mobile sand making and crushing machine on a daily basis