In order to meet production needs, stone factories need to build appropriate production lines. This requires the selection of various large-scale stone crusher equipment according to different production and functional requirements. From coarse crushin

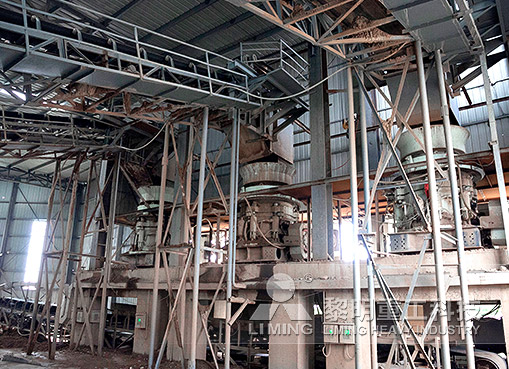

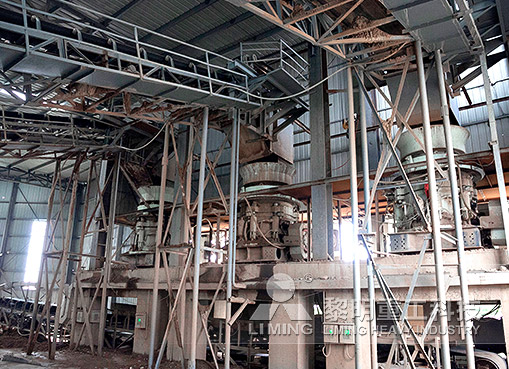

In order to meet production needs, stone factories need to build appropriate production lines. This requires the selection of various large-scale stone crusher equipment according to different production and functional requirements. From coarse crushing to fine crushing, different links must be matched with suitable equipment to make the production line run efficiently and produce stone products that meet the standards. So how to choose the right stone crusher equipment? The following experience is summarized for reference:

Click to consult to learn about the construction plan of the stone crushing production line

(1) Look at the characteristics of the stone

In stone production, the hardness, mud content and water content of the stone are all key data. When selecting the primary crushing equipment, it is necessary to base it on the stone particle size. If the feed is small, it can directly enter the secondary crushing equipment. There are also requirements for the crushing method for stones of different hardness. For stones with too high hardness, such as granite, basalt, and pebbles, it is suitable to use stone crushers and cone crushers; while for stones with lower hardness, such as limestone, it is appropriate to use impact crushers for secondary crushing. In this way, the wear of vulnerable parts such as tooth plates can be effectively reduced, which not only saves production costs, but also significantly improves production efficiency.

(2) Requirements for product quality

Customers' requirements for the particle size and shape of finished stone are key factors in determining which crushing equipment to use. If there are various requirements for the size and specifications of finished stone, crushing equipment alone is not enough, and screening equipment is also required. Through screening, stones can be classified according to different particle sizes to meet a variety of usage scenarios.

(3) Look at the purpose of the finished product

The requirements for sand and gravel aggregates in the construction of various national highways, water conservancy, infrastructure, bridges and other projects are also different. It is necessary to reasonably arrange the stone production equipment according to the configuration of the user's finished stone. For some projects with relatively high requirements for stone, if cracks and sharp corners appear in the stone during construction and use, the risk of project collapse will increase.

Previous: SMP Crusher

Next: SMP Crusher

In order to meet production needs, stone factories need to build appropriate production lines. This requires the selection of various large-scale stone crusher equipment according to different production and functional requirements. From coarse crushin

In order to meet production needs, stone factories need to build appropriate production lines. This requires the selection of various large-scale stone crusher equipment according to different production and functional requirements. From coarse crushing to fine crushing, different links must be matched with suitable equipment to make the production line run efficiently and produce stone products that meet the standards. So how to choose the right stone crusher equipment? The following experience is summarized for reference:

Click to consult to learn about the construction plan of the stone crushing production line

(1) Look at the characteristics of the stone

In stone production, the hardness, mud content and water content of the stone are all key data. When selecting the primary crushing equipment, it is necessary to base it on the stone particle size. If the feed is small, it can directly enter the secondary crushing equipment. There are also requirements for the crushing method for stones of different hardness. For stones with too high hardness, such as granite, basalt, and pebbles, it is suitable to use stone crushers and cone crushers; while for stones with lower hardness, such as limestone, it is appropriate to use impact crushers for secondary crushing. In this way, the wear of vulnerable parts such as tooth plates can be effectively reduced, which not only saves production costs, but also significantly improves production efficiency.

(2) Requirements for product quality

Customers' requirements for the particle size and shape of finished stone are key factors in determining which crushing equipment to use. If there are various requirements for the size and specifications of finished stone, crushing equipment alone is not enough, and screening equipment is also required. Through screening, stones can be classified according to different particle sizes to meet a variety of usage scenarios.

(3) Look at the purpose of the finished product

The requirements for sand and gravel aggregates in the construction of various national highways, water conservancy, infrastructure, bridges and other projects are also different. It is necessary to reasonably arrange the stone production equipment according to the configuration of the user's finished stone. For some projects with relatively high requirements for stone, if cracks and sharp corners appear in the stone during construction and use, the risk of project collapse will increase.

Previous: SMP Crusher

Next: SMP Crusher

How to choose granite vertical shaft impact crusher equipment? How much does one cost?

How to choose granite vertical shaft impact crusher equipment? How much does one cost? What are the large-scale mining crushing machinery with a daily output of about 5,000 tons? How much does it cost?

What are the large-scale mining crushing machinery with a daily output of about 5,000 tons? How much does it cost? How much does it cost for a stone factory to invest in a 500 tons per hour stone crushing production line?

How much does it cost for a stone factory to invest in a 500 tons per hour stone crushing production line? 300 tons per hour potassium and sodium feldspar crushing and sand making production line project: high efficiency and environmental protection

300 tons per hour potassium and sodium feldspar crushing and sand making production line project: high efficiency and environmental protection What are the environmental protection requirements and measures for sand and gravel plants?

What are the environmental protection requirements and measures for sand and gravel plants? How to choose granite vertical shaft impact crusher equipment? How much does one cost?

How to choose granite vertical shaft impact crusher equipment? How much does one cost? What are the large-scale mining crushing machinery with a daily output of about 5,000 tons? How much does it cost?

What are the large-scale mining crushing machinery with a daily output of about 5,000 tons? How much does it cost? How much does it cost for a stone factory to invest in a 500 tons per hour stone crushing production line?

How much does it cost for a stone factory to invest in a 500 tons per hour stone crushing production line? 300 tons per hour potassium and sodium feldspar crushing and sand making production line project: high efficiency and environmental protection

300 tons per hour potassium and sodium feldspar crushing and sand making production line project: high efficiency and environmental protection What are the environmental protection requirements and measures for sand and gravel plants?

What are the environmental protection requirements and measures for sand and gravel plants?