The environmental protection requirements of sand and gravel plants are as follows:Click here to consult about sand and gravel aggregate equipment1. Environmental protection requirements for dust

The environmental protection requirements of sand and gravel plants are as follows:

Click here to consult about sand and gravel aggregate equipment

1. Environmental protection requirements for dust

According to the "Air Pollution Prevention and Control Law", sand and soil and other dust-prone materials should be stored in a sealed manner if they can be sealed. If it is not possible to seal, a strict enclosure that is not lower than the height of the stacked materials should be set up, and effective covering measures should be taken to prevent dust. During the loading and unloading of materials, dust pollution should be prevented and controlled by sealing or spraying.

2. Environmental protection requirements for noise and sewage

According to the "Environmental Noise Pollution Prevention and Control Law", units that generate environmental noise pollution must not only take active measures to control it, but also pay excess pollution fees in accordance with national regulations. According to the "Environmental Protection Law", sand and gravel mining and processing units must comply with national standards in the production and operation of pollutants.

The environmental protection measures of sand and gravel processing plants are as follows:

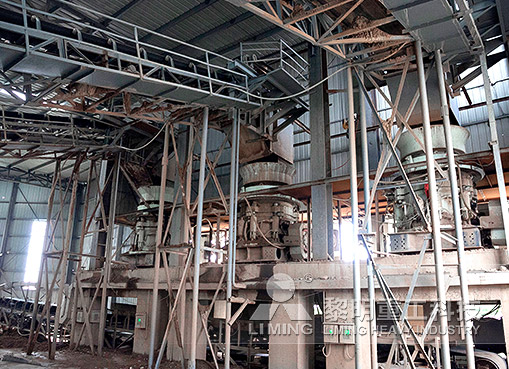

In order to reduce the pollution of sand and gravel yards, a variety of measures can be taken. The dust and exhaust gas in the yard and transportation road are treated by watering and humidification; dust removal equipment is installed on the crusher and screening machine, and the sand and gravel operation area is semi-enclosed with color steel plates when necessary. Water is sprayed to suppress dust before mine blasting, and the blasting is carried out during the period with good atmospheric diffusion to accelerate the dissipation of exhaust gas.

In terms of noise control, the site selection should avoid crowded areas as much as possible. When designing and planning, natural conditions such as hillsides, hills, and woods are cleverly used to block the propagation of noise according to local conditions. For areas with high noise, soundproof sheds can be set up, and the roof and surrounding walls can be sealed and enclosed with soundproof boards to reduce the impact of noise.

Sewage treatment generally includes three links: classification and sorting, mechanical dehydration and natural sedimentation. Wastewater treatment is carried out through the "wastewater collection-regulation-sand settling tank-mixing and mixing tank-sedimentation tank-reuse tank-treated effluent" treatment system.

Previous: SMP Crusher

Next: SMP Crusher

The environmental protection requirements of sand and gravel plants are as follows:Click here to consult about sand and gravel aggregate equipment1. Environmental protection requirements for dust

The environmental protection requirements of sand and gravel plants are as follows:

Click here to consult about sand and gravel aggregate equipment

1. Environmental protection requirements for dust

According to the "Air Pollution Prevention and Control Law", sand and soil and other dust-prone materials should be stored in a sealed manner if they can be sealed. If it is not possible to seal, a strict enclosure that is not lower than the height of the stacked materials should be set up, and effective covering measures should be taken to prevent dust. During the loading and unloading of materials, dust pollution should be prevented and controlled by sealing or spraying.

2. Environmental protection requirements for noise and sewage

According to the "Environmental Noise Pollution Prevention and Control Law", units that generate environmental noise pollution must not only take active measures to control it, but also pay excess pollution fees in accordance with national regulations. According to the "Environmental Protection Law", sand and gravel mining and processing units must comply with national standards in the production and operation of pollutants.

The environmental protection measures of sand and gravel processing plants are as follows:

In order to reduce the pollution of sand and gravel yards, a variety of measures can be taken. The dust and exhaust gas in the yard and transportation road are treated by watering and humidification; dust removal equipment is installed on the crusher and screening machine, and the sand and gravel operation area is semi-enclosed with color steel plates when necessary. Water is sprayed to suppress dust before mine blasting, and the blasting is carried out during the period with good atmospheric diffusion to accelerate the dissipation of exhaust gas.

In terms of noise control, the site selection should avoid crowded areas as much as possible. When designing and planning, natural conditions such as hillsides, hills, and woods are cleverly used to block the propagation of noise according to local conditions. For areas with high noise, soundproof sheds can be set up, and the roof and surrounding walls can be sealed and enclosed with soundproof boards to reduce the impact of noise.

Sewage treatment generally includes three links: classification and sorting, mechanical dehydration and natural sedimentation. Wastewater treatment is carried out through the "wastewater collection-regulation-sand settling tank-mixing and mixing tank-sedimentation tank-reuse tank-treated effluent" treatment system.

Previous: SMP Crusher

Next: SMP Crusher

High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field

High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field Why is the output of crushing equipment not up to standard?

Why is the output of crushing equipment not up to standard? What are the crushing and sand making machinery and equipment? How much does one set cost?

What are the crushing and sand making machinery and equipment? How much does one set cost? Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development How to solve the blockage of cone crusher

How to solve the blockage of cone crusher High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field

High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field Why is the output of crushing equipment not up to standard?

Why is the output of crushing equipment not up to standard? What are the crushing and sand making machinery and equipment? How much does one set cost?

What are the crushing and sand making machinery and equipment? How much does one set cost? Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development How to solve the blockage of cone crusher

How to solve the blockage of cone crusher