The production capacity of the crushing equipment in the stone plant is very high, why is it getting less and less after being used for a short time? In actual production, the output of finished stone is related to many factors. For example: (hardness

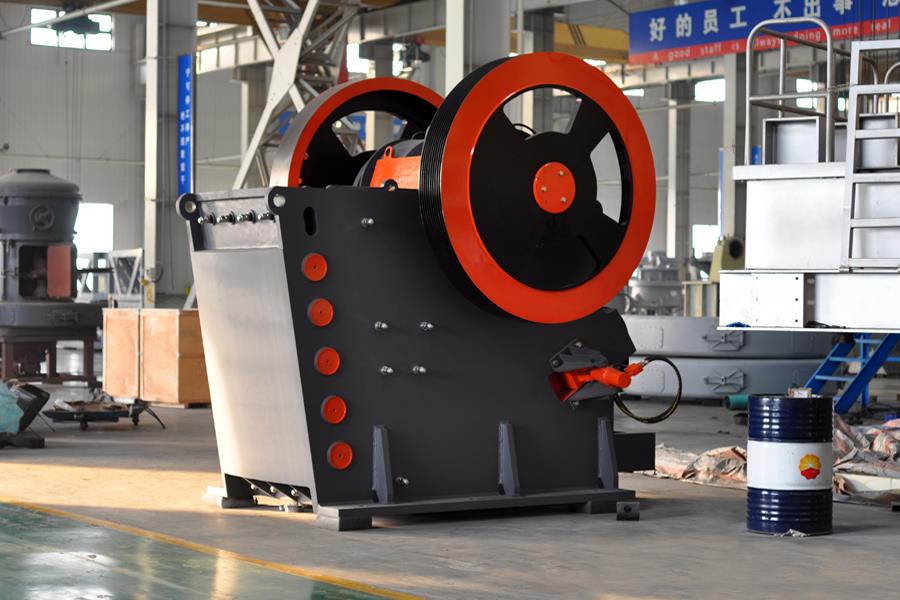

The production capacity of the crushing equipment in the stone plant is very high, why is it getting less and less after being used for a short time? In actual production, the output of finished stone is related to many factors. For example: (hardness of the material, humidity, fineness of the finished material, maintenance and quality of the equipment itself, etc.) There are many factors that affect the output of the stone crusher in the stone plant.

Click to consult to understand the production capacity of crushing equipment

The fineness of the finished stone is different

The higher the fineness requirement, the smaller the crushing capacity of the crusher is usually. If the stone plant has no special requirements, the material fineness is generally set to medium fine. Different models of stone crushers have differences in production capacity and energy consumption. Users need to choose the appropriate stone crusher model according to actual needs to ensure the output of the equipment and avoid unnecessary cost increases.

Whether the production operation is in compliance with the specifications

Standardized operation and regular maintenance have a direct impact on the production capacity of the stone crusher in the stone plant. If the operation is not standardized and there is a lack of regular maintenance, it will cause rapid wear of the equipment's wearing parts, shorten the equipment life, and reduce production per unit time. To ensure the efficient and stable operation of the stone crusher, it is necessary to strictly abide by the operating procedures and implement regular maintenance plans to reduce the failure rate, increase production capacity, and extend the service life of the equipment.

Equipment reliability of stone crusher in stone quarry

A high-quality stone crusher in stone quarry is not only energy-saving and environmentally friendly, but also can easily achieve the expected output. Its manufacturer uses new high-wear-resistant materials and advanced technologies to ensure that the equipment meets user needs and provides strong guarantees for efficient, continuous and safe production. In addition, the design of the stone crushing production line in the stone quarry is crucial, especially the output requirements. For example, if the output is 1,000 tons/hour, it cannot rely solely on the stone crusher to achieve this output. It is also necessary to ensure that the processing capacity of supporting equipment such as feeders and belt conveyors matches, otherwise the overall output will be affected. Therefore, a reasonable design of the production line plan is the key to ensuring efficient production.

Previous: SMP Crusher

Next: SMP Crusher

The production capacity of the crushing equipment in the stone plant is very high, why is it getting less and less after being used for a short time? In actual production, the output of finished stone is related to many factors. For example: (hardness

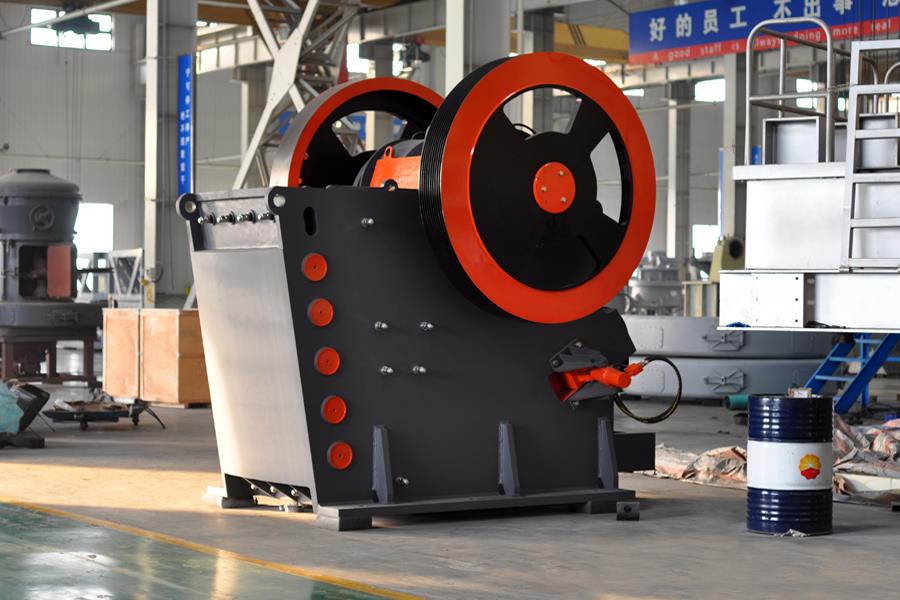

The production capacity of the crushing equipment in the stone plant is very high, why is it getting less and less after being used for a short time? In actual production, the output of finished stone is related to many factors. For example: (hardness of the material, humidity, fineness of the finished material, maintenance and quality of the equipment itself, etc.) There are many factors that affect the output of the stone crusher in the stone plant.

Click to consult to understand the production capacity of crushing equipment

The fineness of the finished stone is different

The higher the fineness requirement, the smaller the crushing capacity of the crusher is usually. If the stone plant has no special requirements, the material fineness is generally set to medium fine. Different models of stone crushers have differences in production capacity and energy consumption. Users need to choose the appropriate stone crusher model according to actual needs to ensure the output of the equipment and avoid unnecessary cost increases.

Whether the production operation is in compliance with the specifications

Standardized operation and regular maintenance have a direct impact on the production capacity of the stone crusher in the stone plant. If the operation is not standardized and there is a lack of regular maintenance, it will cause rapid wear of the equipment's wearing parts, shorten the equipment life, and reduce production per unit time. To ensure the efficient and stable operation of the stone crusher, it is necessary to strictly abide by the operating procedures and implement regular maintenance plans to reduce the failure rate, increase production capacity, and extend the service life of the equipment.

Equipment reliability of stone crusher in stone quarry

A high-quality stone crusher in stone quarry is not only energy-saving and environmentally friendly, but also can easily achieve the expected output. Its manufacturer uses new high-wear-resistant materials and advanced technologies to ensure that the equipment meets user needs and provides strong guarantees for efficient, continuous and safe production. In addition, the design of the stone crushing production line in the stone quarry is crucial, especially the output requirements. For example, if the output is 1,000 tons/hour, it cannot rely solely on the stone crusher to achieve this output. It is also necessary to ensure that the processing capacity of supporting equipment such as feeders and belt conveyors matches, otherwise the overall output will be affected. Therefore, a reasonable design of the production line plan is the key to ensuring efficient production.

Previous: SMP Crusher

Next: SMP Crusher

What are the crushing and sand making machinery and equipment? How much does one set cost?

What are the crushing and sand making machinery and equipment? How much does one set cost? Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development How to solve the blockage of cone crusher

How to solve the blockage of cone crusher What are the price factors of a complete set of granite sand making equipment

What are the price factors of a complete set of granite sand making equipment Impact crusher models with an hourly output of more than 300 tons, how much does one cost

Impact crusher models with an hourly output of more than 300 tons, how much does one cost What are the crushing and sand making machinery and equipment? How much does one set cost?

What are the crushing and sand making machinery and equipment? How much does one set cost? Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development How to solve the blockage of cone crusher

How to solve the blockage of cone crusher What are the price factors of a complete set of granite sand making equipment

What are the price factors of a complete set of granite sand making equipment Impact crusher models with an hourly output of more than 300 tons, how much does one cost

Impact crusher models with an hourly output of more than 300 tons, how much does one cost