Crushing and sand making machinery and equipment are rich and varied, with many models. A complete set of equipment covers a variety of core crushing and sand making equipment, such as jaw, impact, cone crusher and sand making machine, etc., and is als

Crushing and sand making machinery and equipment are rich and varied, with many models. A complete set of equipment covers a variety of core crushing and sand making equipment, such as jaw, impact, cone crusher and sand making machine, etc., and is also equipped with auxiliary equipment such as feeder, conveyor, vibrating screen, etc. The equipment works together to meet different production needs.

Click to consult to learn about crushing and sand making equipment

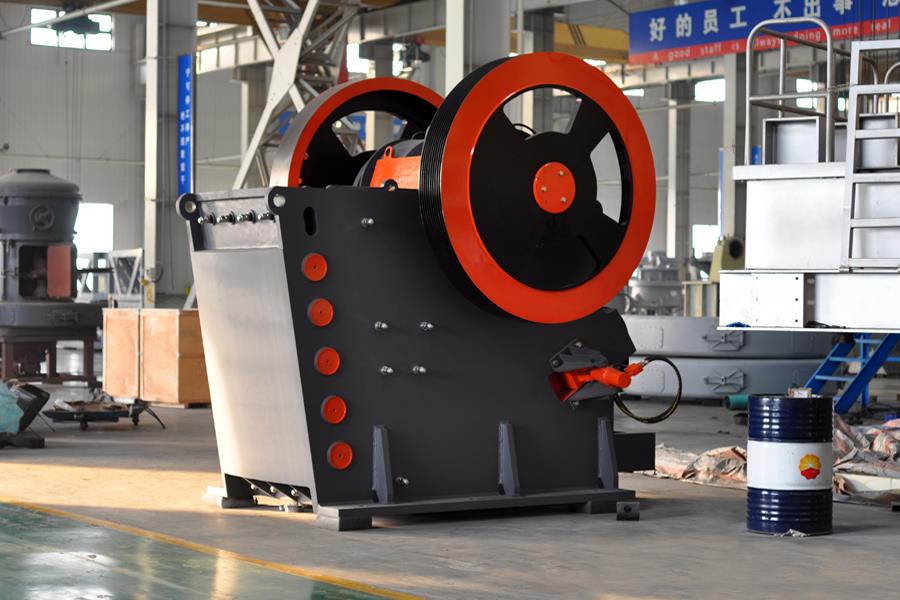

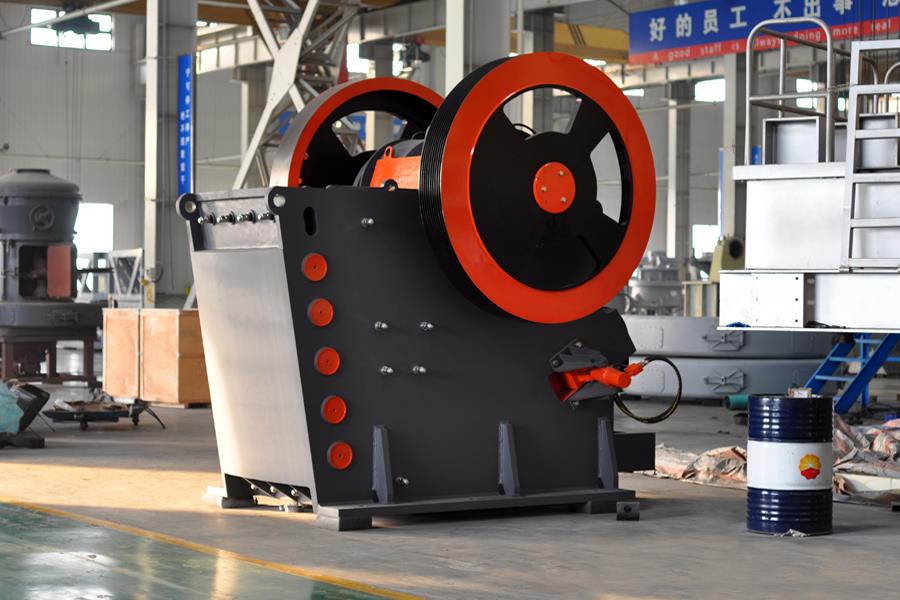

1. Jaw crusher

The jaw crusher is a high-quality primary crushing equipment, especially suitable for crushing high-hardness raw materials. It occupies a small area, but has a great crushing ratio, and the maximum feed particle size can reach 1200mm. The equipment is easy to maintain, and the failure rate is relatively low among many crushing equipment. When processing hard materials, it has excellent performance and performs very well.

2. Impact crusher

The impact crusher and the jaw crusher are a golden pair. After the jaw crusher completes the primary crushing, the impact crusher relays as the second crushing equipment to reprocess the small particles after the jaw crusher. After the impact crusher is crushed, the finished product has a finer particle shape, which greatly creates convenient conditions for subsequent sand making operations and improves overall production efficiency.

3. Cone crusher

It is also suitable for medium crushing, and is more suitable for harder materials (basalt, granite...). It adopts the principle of laminated crushing. The mortar wall moves toward the crushing wall to squeeze the material. It can handle particle size ≤800mm. The discharge port is adjusted by a hydraulic motor, and the adjustment operation is convenient. The range is 3-60mm. The service life of the wearing parts is long, which solves the problem of high operating costs in the later stage.

4. Sand making machine

The sand making machine is powerful and can accurately process medium and fine crushed stones into sand and gravel with different moduli. The fineness of its finished product can be flexibly adjusted to meet various needs. Not only that, it has outstanding cost performance and is widely used in many fields such as construction and roads. With its excellent performance, it has become a powerful equipment for sand and gravel production.

How much does a set of crushing and sand making equipment cost?

The price of a set of crushing and sand making machinery and equipment is calculated according to the model of the mechanical equipment composed. The price of different combinations is different. Of course, the price of the same model of equipment from different manufacturers will also be different, because each manufacturer has different sales models, production processes, materials, etc. At present, a set of equipment costs at least hundreds of thousands or even millions, and the highest is several million.

Previous: SMP Crusher

Next: SMP Crusher

Crushing and sand making machinery and equipment are rich and varied, with many models. A complete set of equipment covers a variety of core crushing and sand making equipment, such as jaw, impact, cone crusher and sand making machine, etc., and is als

Crushing and sand making machinery and equipment are rich and varied, with many models. A complete set of equipment covers a variety of core crushing and sand making equipment, such as jaw, impact, cone crusher and sand making machine, etc., and is also equipped with auxiliary equipment such as feeder, conveyor, vibrating screen, etc. The equipment works together to meet different production needs.

Click to consult to learn about crushing and sand making equipment

1. Jaw crusher

The jaw crusher is a high-quality primary crushing equipment, especially suitable for crushing high-hardness raw materials. It occupies a small area, but has a great crushing ratio, and the maximum feed particle size can reach 1200mm. The equipment is easy to maintain, and the failure rate is relatively low among many crushing equipment. When processing hard materials, it has excellent performance and performs very well.

2. Impact crusher

The impact crusher and the jaw crusher are a golden pair. After the jaw crusher completes the primary crushing, the impact crusher relays as the second crushing equipment to reprocess the small particles after the jaw crusher. After the impact crusher is crushed, the finished product has a finer particle shape, which greatly creates convenient conditions for subsequent sand making operations and improves overall production efficiency.

3. Cone crusher

It is also suitable for medium crushing, and is more suitable for harder materials (basalt, granite...). It adopts the principle of laminated crushing. The mortar wall moves toward the crushing wall to squeeze the material. It can handle particle size ≤800mm. The discharge port is adjusted by a hydraulic motor, and the adjustment operation is convenient. The range is 3-60mm. The service life of the wearing parts is long, which solves the problem of high operating costs in the later stage.

4. Sand making machine

The sand making machine is powerful and can accurately process medium and fine crushed stones into sand and gravel with different moduli. The fineness of its finished product can be flexibly adjusted to meet various needs. Not only that, it has outstanding cost performance and is widely used in many fields such as construction and roads. With its excellent performance, it has become a powerful equipment for sand and gravel production.

How much does a set of crushing and sand making equipment cost?

The price of a set of crushing and sand making machinery and equipment is calculated according to the model of the mechanical equipment composed. The price of different combinations is different. Of course, the price of the same model of equipment from different manufacturers will also be different, because each manufacturer has different sales models, production processes, materials, etc. At present, a set of equipment costs at least hundreds of thousands or even millions, and the highest is several million.

Previous: SMP Crusher

Next: SMP Crusher

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development How to solve the blockage of cone crusher

How to solve the blockage of cone crusher What are the price factors of a complete set of granite sand making equipment

What are the price factors of a complete set of granite sand making equipment Impact crusher models with an hourly output of more than 300 tons, how much does one cost

Impact crusher models with an hourly output of more than 300 tons, how much does one cost What are the types of sand making machines? How much does one cost?

What are the types of sand making machines? How much does one cost? Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development How to solve the blockage of cone crusher

How to solve the blockage of cone crusher What are the price factors of a complete set of granite sand making equipment

What are the price factors of a complete set of granite sand making equipment Impact crusher models with an hourly output of more than 300 tons, how much does one cost

Impact crusher models with an hourly output of more than 300 tons, how much does one cost What are the types of sand making machines? How much does one cost?

What are the types of sand making machines? How much does one cost?