The project is located in Jiangxi Province and has built an efficient and environmentally friendly potassium-sodium feldspar crushing and sand-making production line to provide high-quality machine-made sand raw materials for surrounding commercial mix

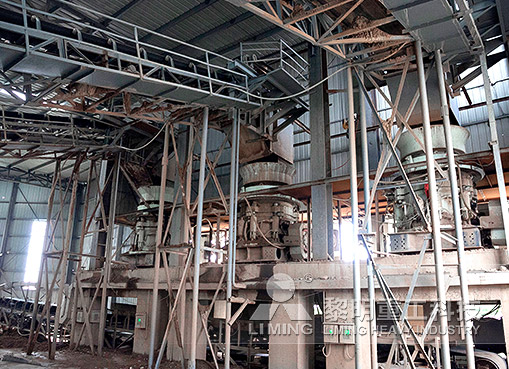

The project is located in Jiangxi Province and has built an efficient and environmentally friendly potassium-sodium feldspar crushing and sand-making production line to provide high-quality machine-made sand raw materials for surrounding commercial mixing stations.

Click here to consult for details on the construction plan of the crushing and sand-making production line

Project Overview

Raw materials: potassium-sodium feldspar

Capacity: 300 tons/hour

Discharge size: 0-5 mm

Finished product use: surrounding commercial mixing stations

Process flow

The production line adopts a three-stage crushing process to ensure that the particle shape and gradation of the finished sand meet the use requirements of the commercial mixing station:

Coarse crushing stage:

The potassium-sodium feldspar raw materials first enter the PEW jaw crusher for coarse crushing, crushing the large pieces of material to medium particle size.

Medium crushing stage:

The coarsely crushed materials enter the HST single-cylinder hydraulic cone crusher for secondary crushing, further reducing the material particle size and preparing for the sand making stage.

Sand making stage:

The medium-crushed materials enter the VSI6X impact crusher (sand making machine) for sand making, and finally produce 0-5 mm high-quality fine sand.

Project advantages

1. Technology and reliable equipment:

Adopt a fully automatic control system to achieve real-time monitoring of the production process and ensure production efficiency and product quality.

Key components are made of high-quality materials and advanced processing technology to ensure stable and reliable performance of the equipment, reduce failure rate and extend equipment service life.

2. High quality of finished sand and gravel:

The production line has high operating efficiency, stable output, rounded machine-made sand particles and reasonable grading. It can completely replace natural river sand and meet the strict requirements of commercial mixing stations for sand and gravel quality.

The production line can flexibly adjust the production mode according to actual needs, realize stone crushing and shaping functions, and meet the diverse needs of different customers.

3. Low cost and convenient operation and maintenance:

The production line is reasonably designed, with high production efficiency and low operating cost, creating higher economic benefits for customers.

The main equipment is equipped with a full thin oil lubrication station and a hydraulic jacking device, which is convenient and quick to maintain, reduce labor costs and improve equipment operation efficiency.

Equipment configuration

PEW jaw crusher: High-efficiency coarse crushing equipment with strong processing capacity and stable and reliable operation.

HST single cylinder hydraulic cone crusher: medium crushing equipment, large crushing ratio, good product particle shape.

VSI6X impact crusher (sand making machine): sand making equipment, excellent finished sand particle shape and reasonable grading.

S5X vibrating screen: used to screen materials of different particle sizes to ensure the quality of finished sand.

Previous: SMP Crusher

Next: SMP Crusher

The project is located in Jiangxi Province and has built an efficient and environmentally friendly potassium-sodium feldspar crushing and sand-making production line to provide high-quality machine-made sand raw materials for surrounding commercial mix

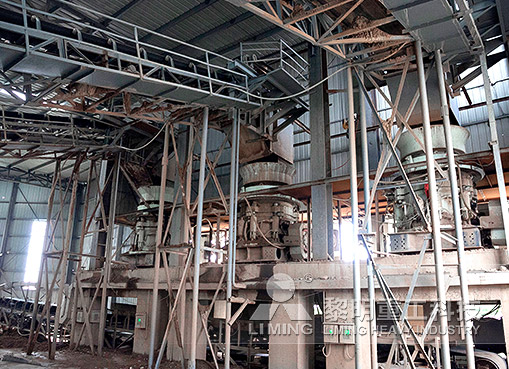

The project is located in Jiangxi Province and has built an efficient and environmentally friendly potassium-sodium feldspar crushing and sand-making production line to provide high-quality machine-made sand raw materials for surrounding commercial mixing stations.

Click here to consult for details on the construction plan of the crushing and sand-making production line

Project Overview

Raw materials: potassium-sodium feldspar

Capacity: 300 tons/hour

Discharge size: 0-5 mm

Finished product use: surrounding commercial mixing stations

Process flow

The production line adopts a three-stage crushing process to ensure that the particle shape and gradation of the finished sand meet the use requirements of the commercial mixing station:

Coarse crushing stage:

The potassium-sodium feldspar raw materials first enter the PEW jaw crusher for coarse crushing, crushing the large pieces of material to medium particle size.

Medium crushing stage:

The coarsely crushed materials enter the HST single-cylinder hydraulic cone crusher for secondary crushing, further reducing the material particle size and preparing for the sand making stage.

Sand making stage:

The medium-crushed materials enter the VSI6X impact crusher (sand making machine) for sand making, and finally produce 0-5 mm high-quality fine sand.

Project advantages

1. Technology and reliable equipment:

Adopt a fully automatic control system to achieve real-time monitoring of the production process and ensure production efficiency and product quality.

Key components are made of high-quality materials and advanced processing technology to ensure stable and reliable performance of the equipment, reduce failure rate and extend equipment service life.

2. High quality of finished sand and gravel:

The production line has high operating efficiency, stable output, rounded machine-made sand particles and reasonable grading. It can completely replace natural river sand and meet the strict requirements of commercial mixing stations for sand and gravel quality.

The production line can flexibly adjust the production mode according to actual needs, realize stone crushing and shaping functions, and meet the diverse needs of different customers.

3. Low cost and convenient operation and maintenance:

The production line is reasonably designed, with high production efficiency and low operating cost, creating higher economic benefits for customers.

The main equipment is equipped with a full thin oil lubrication station and a hydraulic jacking device, which is convenient and quick to maintain, reduce labor costs and improve equipment operation efficiency.

Equipment configuration

PEW jaw crusher: High-efficiency coarse crushing equipment with strong processing capacity and stable and reliable operation.

HST single cylinder hydraulic cone crusher: medium crushing equipment, large crushing ratio, good product particle shape.

VSI6X impact crusher (sand making machine): sand making equipment, excellent finished sand particle shape and reasonable grading.

S5X vibrating screen: used to screen materials of different particle sizes to ensure the quality of finished sand.

Previous: SMP Crusher

Next: SMP Crusher

What are the environmental protection requirements and measures for sand and gravel plants?

What are the environmental protection requirements and measures for sand and gravel plants? High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field

High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field Why is the output of crushing equipment not up to standard?

Why is the output of crushing equipment not up to standard? What are the crushing and sand making machinery and equipment? How much does one set cost?

What are the crushing and sand making machinery and equipment? How much does one set cost? Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development What are the environmental protection requirements and measures for sand and gravel plants?

What are the environmental protection requirements and measures for sand and gravel plants? High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field

High energy and low consumption sand making medium and fine crushing equipment: cone crusher application field Why is the output of crushing equipment not up to standard?

Why is the output of crushing equipment not up to standard? What are the crushing and sand making machinery and equipment? How much does one set cost?

What are the crushing and sand making machinery and equipment? How much does one set cost? Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development

Shandongs annual output of 3 million tons of solid waste crushing and sand making production line is a model of green mine development