"Granite is hard and difficult to process. Choosing the right equipment is the key: jaw crusher for coarse crushing → cone crusher for medium and fine crushing → vibrating screen for classification → vertical shaft impact crusher for sand ma

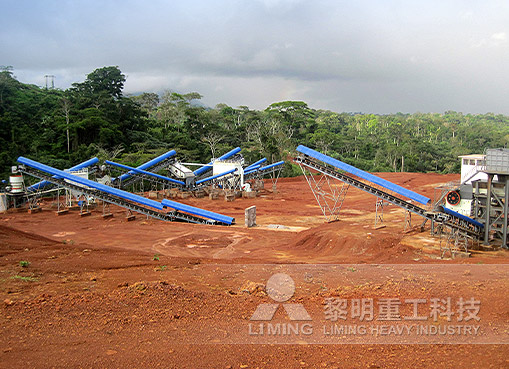

"Granite is hard and difficult to process. Choosing the right equipment is the key: jaw crusher for coarse crushing → cone crusher for medium and fine crushing → vibrating screen for classification → vertical shaft impact crusher for sand making → sand washing and impurity removal. The efficient production line can also recycle wastewater and waste."

Granite is an intrusive rock in magmatic rock. The main mineral components are quartz, potassium feldspar and acidic plagioclase. Among them, the content of quartz is relatively high, up to 50-60%, which leads to the high hardness of granite and greater processing difficulty. So, how to choose equipment for granite stone production line?

Click to consult to understand the construction plan of granite stone production line

1. Coarse crushing equipment

In the stone processing process, jaw crushers are usually used. The granite mined from the mountain is transported to the ore bin by a dump truck, and then the granite is sent to the jaw crusher in a uniform and stable state with the help of a vibrating feeder for coarse crushing. The coarsely crushed stone will be transported to the medium crushing buffer bin.

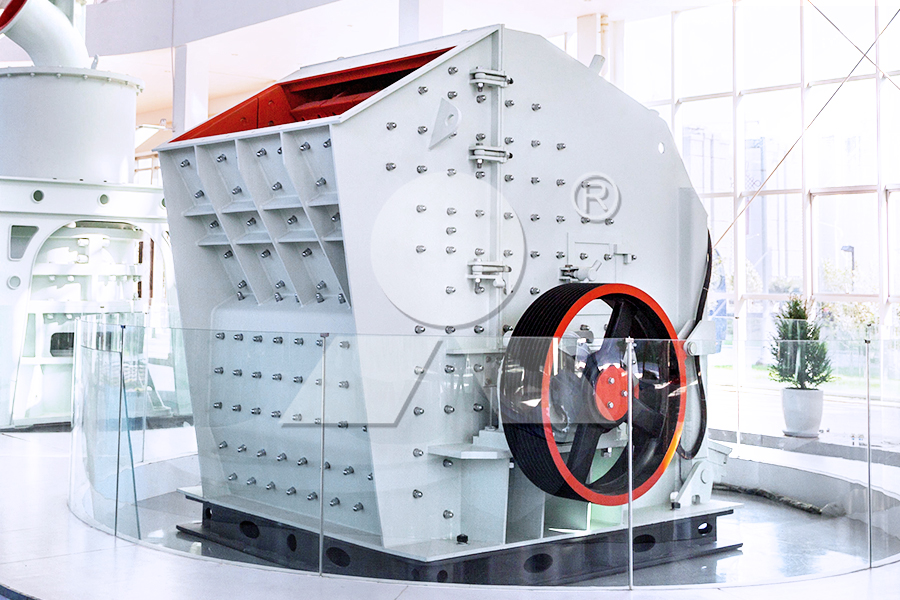

2. Medium and fine crushing equipment

Granite is hard, and cone crushers are generally used in the medium and fine crushing stages. In actual production, a combination of single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher can be used. This method has higher crushing efficiency and can reduce machine wear. It is very suitable for large-scale granite stone production lines. The crushed stones will be transported to the screening workshop.

3. Screening equipment

The medium and fine crushed materials are guided by the conveyor and the pre-screening bulk material chute and sent to the vibrating screen for classification. Stones with a particle size of more than 31.5mm are sent to the fine crushing buffer ore bin for temporary storage; stones with a particle size of less than 31.5mm can be accurately sorted into 5-10mm, 10-20mm, 20-31.5mm and other specifications of stones after screening.

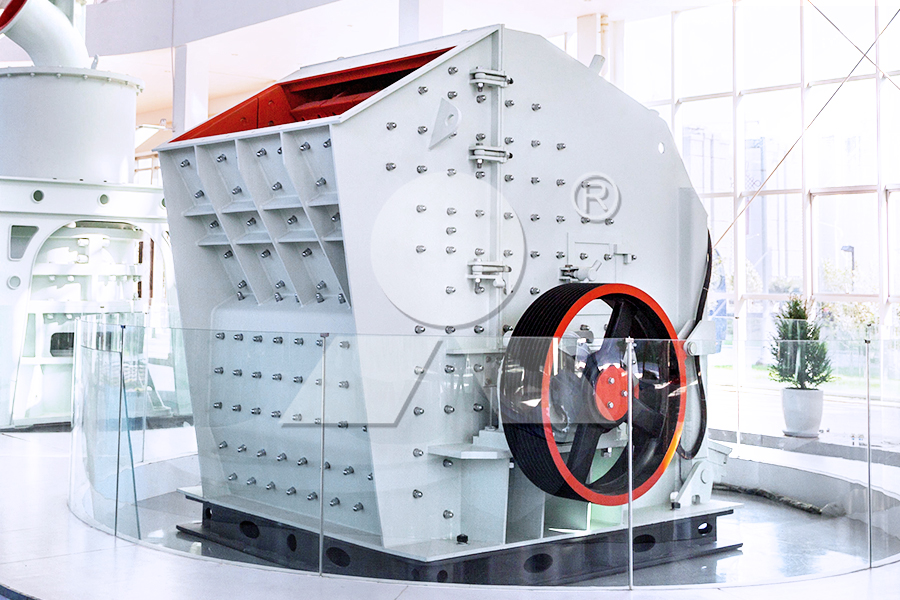

4. Shaping sand making equipment

In the shaping sand making process, vertical shaft impact crushers are usually used. This equipment has two crushing modes: stone-on-stone and stone-on-iron. It has various functions and can not only shape the stone but also realize sand making operations. With its excellent performance, it can eventually produce high-quality machine-made sand with a particle size of 0-5mm.

5. Sand washing equipment

If you want to remove impurities, you can send the output finished sand to the sand washing machine for cleaning, and after being processed by the dewatering screen, it is stored in the finished product silo by the conveyor.

After flocculation and concentration, the sewage is filtered by the filter press. The overflow liquid of the concentrator and the filtrate of the filter press enter the circulating water pool in the factory area, which is reused without discharge. The mud cake can be used as raw material for the brick factory.

Previous: SMP Crusher

Next: SMP Crusher

"Granite is hard and difficult to process. Choosing the right equipment is the key: jaw crusher for coarse crushing → cone crusher for medium and fine crushing → vibrating screen for classification → vertical shaft impact crusher for sand ma

"Granite is hard and difficult to process. Choosing the right equipment is the key: jaw crusher for coarse crushing → cone crusher for medium and fine crushing → vibrating screen for classification → vertical shaft impact crusher for sand making → sand washing and impurity removal. The efficient production line can also recycle wastewater and waste."

Granite is an intrusive rock in magmatic rock. The main mineral components are quartz, potassium feldspar and acidic plagioclase. Among them, the content of quartz is relatively high, up to 50-60%, which leads to the high hardness of granite and greater processing difficulty. So, how to choose equipment for granite stone production line?

Click to consult to understand the construction plan of granite stone production line

1. Coarse crushing equipment

In the stone processing process, jaw crushers are usually used. The granite mined from the mountain is transported to the ore bin by a dump truck, and then the granite is sent to the jaw crusher in a uniform and stable state with the help of a vibrating feeder for coarse crushing. The coarsely crushed stone will be transported to the medium crushing buffer bin.

2. Medium and fine crushing equipment

Granite is hard, and cone crushers are generally used in the medium and fine crushing stages. In actual production, a combination of single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher can be used. This method has higher crushing efficiency and can reduce machine wear. It is very suitable for large-scale granite stone production lines. The crushed stones will be transported to the screening workshop.

3. Screening equipment

The medium and fine crushed materials are guided by the conveyor and the pre-screening bulk material chute and sent to the vibrating screen for classification. Stones with a particle size of more than 31.5mm are sent to the fine crushing buffer ore bin for temporary storage; stones with a particle size of less than 31.5mm can be accurately sorted into 5-10mm, 10-20mm, 20-31.5mm and other specifications of stones after screening.

4. Shaping sand making equipment

In the shaping sand making process, vertical shaft impact crushers are usually used. This equipment has two crushing modes: stone-on-stone and stone-on-iron. It has various functions and can not only shape the stone but also realize sand making operations. With its excellent performance, it can eventually produce high-quality machine-made sand with a particle size of 0-5mm.

5. Sand washing equipment

If you want to remove impurities, you can send the output finished sand to the sand washing machine for cleaning, and after being processed by the dewatering screen, it is stored in the finished product silo by the conveyor.

After flocculation and concentration, the sewage is filtered by the filter press. The overflow liquid of the concentrator and the filtrate of the filter press enter the circulating water pool in the factory area, which is reused without discharge. The mud cake can be used as raw material for the brick factory.

Previous: SMP Crusher

Next: SMP Crusher

How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction

Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction

Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction