The production line with an hourly output of 500 tons of stones is configured as follows:Raw material: limestoneFinished product size: 0-5-10-20-31.5mmFinished product use: mixing station

The production line with an hourly output of 500 tons of stones is configured as follows:

Raw material: limestone

Finished product size: 0-5-10-20-31.5mm

Finished product use: mixing station

Design capacity: 500 tons per hour

Understand the stone production line construction plan click consultation

Main equipment:

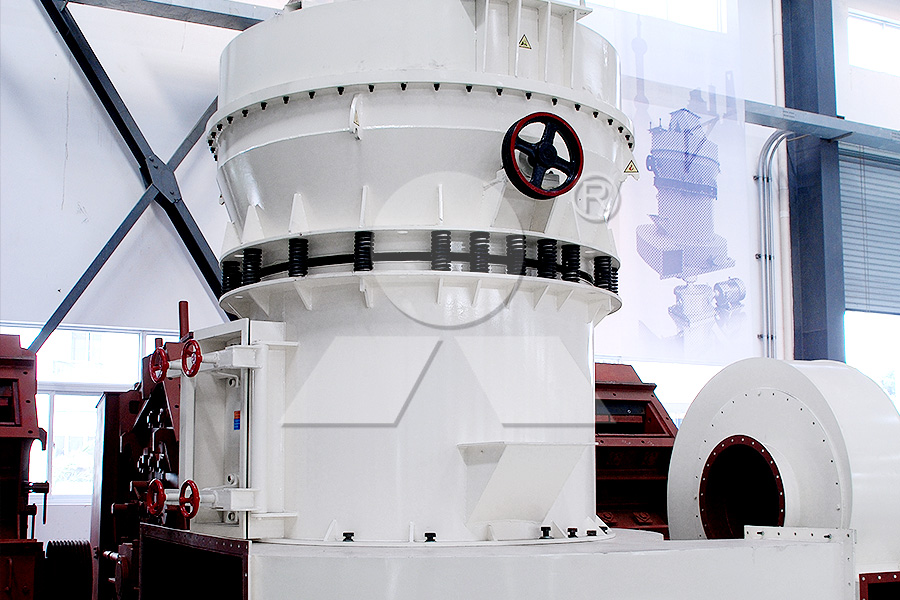

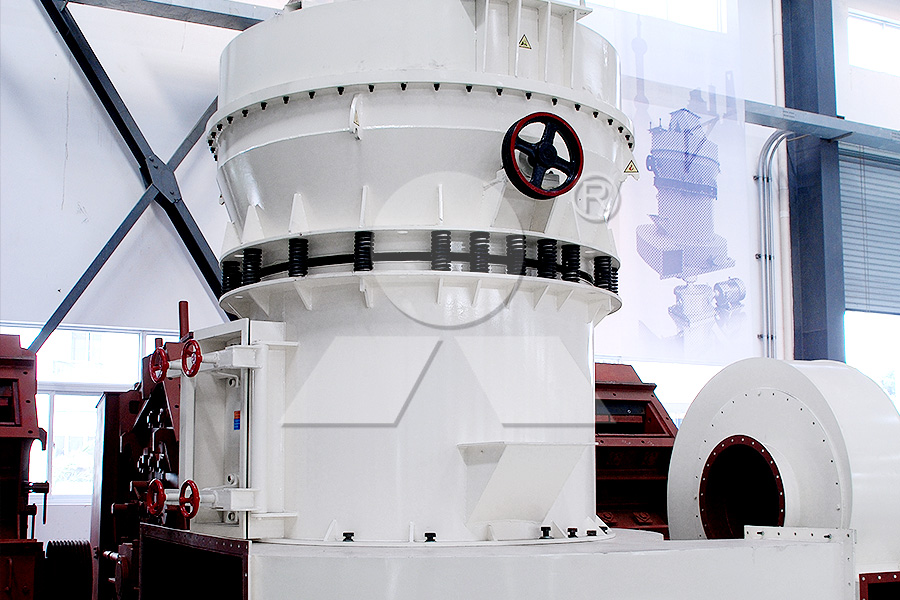

PEW Jaw Crusher CI5X Counterattack Crusher S5X Vibrating Screening Equipment

Process flow

The limestone is pre-screened by the F5X1360 feeder, and after the fine material and muck are removed, the fine material is directly sent to the Ebei break discharge belt, and the coarse material is re-entered into the transfer bin through the Ebei break. Subsequently, the material is sent to the CI5X1520 by the belt for hydraulic counterattack and thinning. The product is screened by S5X2460-2, and the large particles are broken back by PF1315 to obtain 20-31.5mm crushed stone. The remaining fine material is divided into 0-5, 10 and 20mm finished products by S5X2460-3 fine screen to realize efficient grading treatment.

Previous: SMP Crusher

Next: SMP Crusher

The production line with an hourly output of 500 tons of stones is configured as follows:Raw material: limestoneFinished product size: 0-5-10-20-31.5mmFinished product use: mixing station

The production line with an hourly output of 500 tons of stones is configured as follows:

Raw material: limestone

Finished product size: 0-5-10-20-31.5mm

Finished product use: mixing station

Design capacity: 500 tons per hour

Understand the stone production line construction plan click consultation

Main equipment:

PEW Jaw Crusher CI5X Counterattack Crusher S5X Vibrating Screening Equipment

Process flow

The limestone is pre-screened by the F5X1360 feeder, and after the fine material and muck are removed, the fine material is directly sent to the Ebei break discharge belt, and the coarse material is re-entered into the transfer bin through the Ebei break. Subsequently, the material is sent to the CI5X1520 by the belt for hydraulic counterattack and thinning. The product is screened by S5X2460-2, and the large particles are broken back by PF1315 to obtain 20-31.5mm crushed stone. The remaining fine material is divided into 0-5, 10 and 20mm finished products by S5X2460-3 fine screen to realize efficient grading treatment.

Previous: SMP Crusher

Next: SMP Crusher

What are the large gravel crushers with a daily output of 10000 tons? How much is it

What are the large gravel crushers with a daily output of 10000 tons? How much is it What are the mechanism sand equipment? About how much

What are the mechanism sand equipment? About how much Model parameters of gyratory crusher

Model parameters of gyratory crusher Introduction of river pebble sand making machine and manufacturer

Introduction of river pebble sand making machine and manufacturer Process Flow of 100-120 Tons of Limestone Fine Sand Production Line

Process Flow of 100-120 Tons of Limestone Fine Sand Production Line What are the large gravel crushers with a daily output of 10000 tons? How much is it

What are the large gravel crushers with a daily output of 10000 tons? How much is it What are the mechanism sand equipment? About how much

What are the mechanism sand equipment? About how much Model parameters of gyratory crusher

Model parameters of gyratory crusher Introduction of river pebble sand making machine and manufacturer

Introduction of river pebble sand making machine and manufacturer Process Flow of 100-120 Tons of Limestone Fine Sand Production Line

Process Flow of 100-120 Tons of Limestone Fine Sand Production Line