In construction engineering, sand and gravel aggregates, as a major component of concrete, account for 60% to 80% of its weight, directly affecting the strength and durability of the entire building structure. Therefore, improving the quality of sand a

In construction engineering, sand and gravel aggregates, as a major component of concrete, account for 60% to 80% of its weight, directly affecting the strength and durability of the entire building structure. Therefore, improving the quality of sand and gravel aggregates is a crucial step in ensuring the quality of concrete construction. All of this relies on the scientific and rational selection and application of crushing equipment.

More Sand and Gravel Aggregate Crushing Equipment Configuration Cases

I. Unveiling the Crushing Mechanism: A Multifaceted Approach to Mechanical Energy

The crushing of sand and gravel aggregates is essentially a process of mechanical energy acting on the stone. This process is complex and sophisticated, encompassing various crushing mechanisms such as compression, splitting, fracturing, shearing, and impact. In actual operation, these mechanisms often intertwine and work together on the stone to achieve efficient crushing.

II. Smart Selection: Multi-dimensional Consideration, Precise Matching

1. Raw Material Characteristics First

The primary consideration in selecting equipment for a stone crushing production line is the type and hardness of the raw material. From the softness of limestone to the hardness of granite, different rock characteristics require different crushers. For example, soft and brittle rocks are suitable for jaw crushers, impact crushers, or hammer crushers; while hard and brittle rocks require the precise operation of cone crushers and shaping crushers.

2. Performance and Applicability are Equally Important

The performance and applicability of the crusher are equally crucial. Jaw crushers are known for their large crushing ratio and are suitable for coarse crushing operations; cone crushers and impact crushers demonstrate excellent performance in medium and fine crushing and can produce products with good particle shape. At the same time, the appropriate model must be selected according to the hardness of the stone to ensure crushing efficiency and quality.

3. Matching Output with Demand

The design of the production line must also fully consider output requirements to ensure efficient matching and coordinated operation between equipment. In addition, for crushed stones with special particle shape requirements, shaping crushers are also required for fine processing.

III. Precise Configuration of Basalt Crushing Production Line

Taking basalt as an example, its high hardness and abrasiveness place higher demands on crushing equipment. In the crushing process design, we adopt crushing equipment based on the layering principle to reduce wear on wear-resistant parts and improve crushing efficiency. Overview of the Four-Stage Production Line:

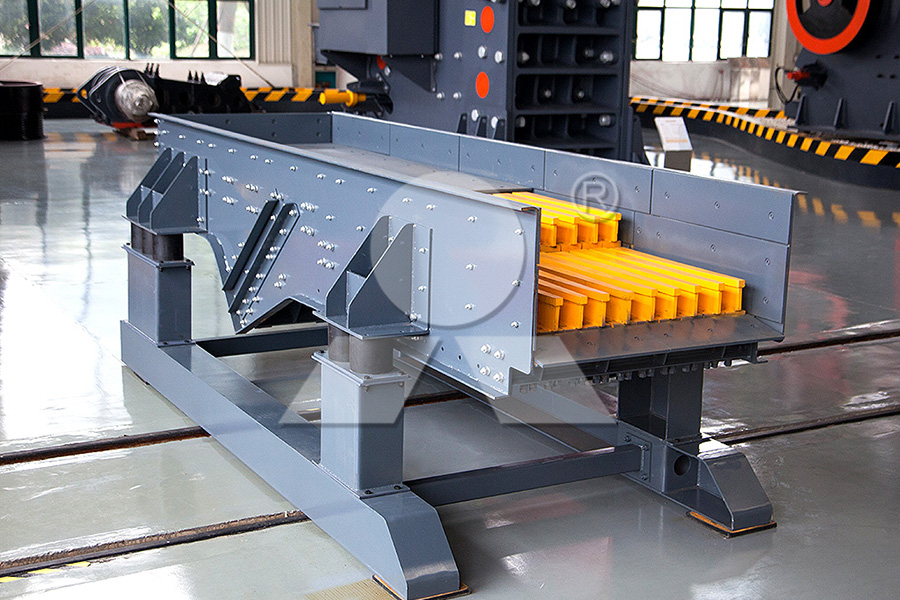

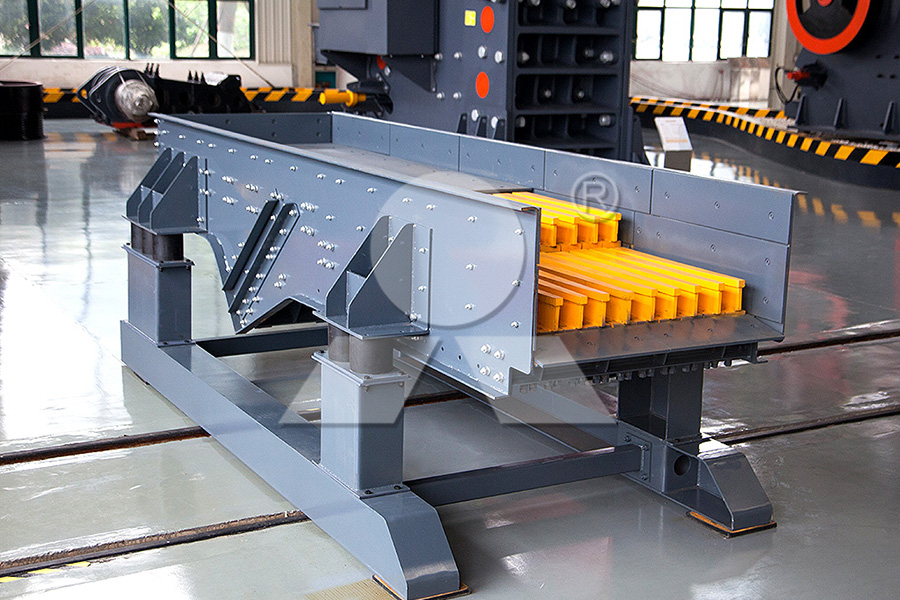

Feeding: A vibrating feeder provides precise material feeding.

Coarse Crushing: A jaw crusher crushes the aggregate to the appropriate particle size.

Medium Crushing: A cone crusher or fine jaw crusher further refines the particle size.

Fine Crushing: An impact crusher or cone crusher produces high-quality crushed stone.

Screening and Dust Removal: A vibrating screen selects qualified crushed stone, and a dry dust collector ensures a clean environment.

Shaping: Unqualified crushed stone is further processed to ensure perfect particle shape.

Conveying: Belt conveyors achieve fully automated conveying.

It is worth noting that the configuration of dust removal equipment needs to be flexibly adjusted according to the cleanliness of the crushed stone and process requirements. Through this series of refined equipment selection and process design, we can not only effectively improve the processing quality of sand and gravel aggregates, but also provide a solid material guarantee for concrete construction.

Previous: SMP Crusher

Next: SMP Crusher

In construction engineering, sand and gravel aggregates, as a major component of concrete, account for 60% to 80% of its weight, directly affecting the strength and durability of the entire building structure. Therefore, improving the quality of sand a

In construction engineering, sand and gravel aggregates, as a major component of concrete, account for 60% to 80% of its weight, directly affecting the strength and durability of the entire building structure. Therefore, improving the quality of sand and gravel aggregates is a crucial step in ensuring the quality of concrete construction. All of this relies on the scientific and rational selection and application of crushing equipment.

More Sand and Gravel Aggregate Crushing Equipment Configuration Cases

I. Unveiling the Crushing Mechanism: A Multifaceted Approach to Mechanical Energy

The crushing of sand and gravel aggregates is essentially a process of mechanical energy acting on the stone. This process is complex and sophisticated, encompassing various crushing mechanisms such as compression, splitting, fracturing, shearing, and impact. In actual operation, these mechanisms often intertwine and work together on the stone to achieve efficient crushing.

II. Smart Selection: Multi-dimensional Consideration, Precise Matching

1. Raw Material Characteristics First

The primary consideration in selecting equipment for a stone crushing production line is the type and hardness of the raw material. From the softness of limestone to the hardness of granite, different rock characteristics require different crushers. For example, soft and brittle rocks are suitable for jaw crushers, impact crushers, or hammer crushers; while hard and brittle rocks require the precise operation of cone crushers and shaping crushers.

2. Performance and Applicability are Equally Important

The performance and applicability of the crusher are equally crucial. Jaw crushers are known for their large crushing ratio and are suitable for coarse crushing operations; cone crushers and impact crushers demonstrate excellent performance in medium and fine crushing and can produce products with good particle shape. At the same time, the appropriate model must be selected according to the hardness of the stone to ensure crushing efficiency and quality.

3. Matching Output with Demand

The design of the production line must also fully consider output requirements to ensure efficient matching and coordinated operation between equipment. In addition, for crushed stones with special particle shape requirements, shaping crushers are also required for fine processing.

III. Precise Configuration of Basalt Crushing Production Line

Taking basalt as an example, its high hardness and abrasiveness place higher demands on crushing equipment. In the crushing process design, we adopt crushing equipment based on the layering principle to reduce wear on wear-resistant parts and improve crushing efficiency. Overview of the Four-Stage Production Line:

Feeding: A vibrating feeder provides precise material feeding.

Coarse Crushing: A jaw crusher crushes the aggregate to the appropriate particle size.

Medium Crushing: A cone crusher or fine jaw crusher further refines the particle size.

Fine Crushing: An impact crusher or cone crusher produces high-quality crushed stone.

Screening and Dust Removal: A vibrating screen selects qualified crushed stone, and a dry dust collector ensures a clean environment.

Shaping: Unqualified crushed stone is further processed to ensure perfect particle shape.

Conveying: Belt conveyors achieve fully automated conveying.

It is worth noting that the configuration of dust removal equipment needs to be flexibly adjusted according to the cleanliness of the crushed stone and process requirements. Through this series of refined equipment selection and process design, we can not only effectively improve the processing quality of sand and gravel aggregates, but also provide a solid material guarantee for concrete construction.

Previous: SMP Crusher

Next: SMP Crusher

Shibang Gansu Lintao 500-ton-per-hour basalt crushing and sand making project

Shibang Gansu Lintao 500-ton-per-hour basalt crushing and sand making project Advantages of the C6X jaw crusher for basalt crushing

Advantages of the C6X jaw crusher for basalt crushing Configuration of a silicon ore crushing and processing production line

Configuration of a silicon ore crushing and processing production line Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project

Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project What types of sand making machines have a capacity of 100 tons per hour? How much does one cost?

What types of sand making machines have a capacity of 100 tons per hour? How much does one cost? Shibang Gansu Lintao 500-ton-per-hour basalt crushing and sand making project

Shibang Gansu Lintao 500-ton-per-hour basalt crushing and sand making project Advantages of the C6X jaw crusher for basalt crushing

Advantages of the C6X jaw crusher for basalt crushing Configuration of a silicon ore crushing and processing production line

Configuration of a silicon ore crushing and processing production line Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project

Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project What types of sand making machines have a capacity of 100 tons per hour? How much does one cost?

What types of sand making machines have a capacity of 100 tons per hour? How much does one cost?