Raymond mill after a period of time, it is necessary to maintain and repair the equipment, if the maintenance and repair is not in place equipment at work will fail, bring inconvenience to our work, such as Raymond mill in the work of the phenome

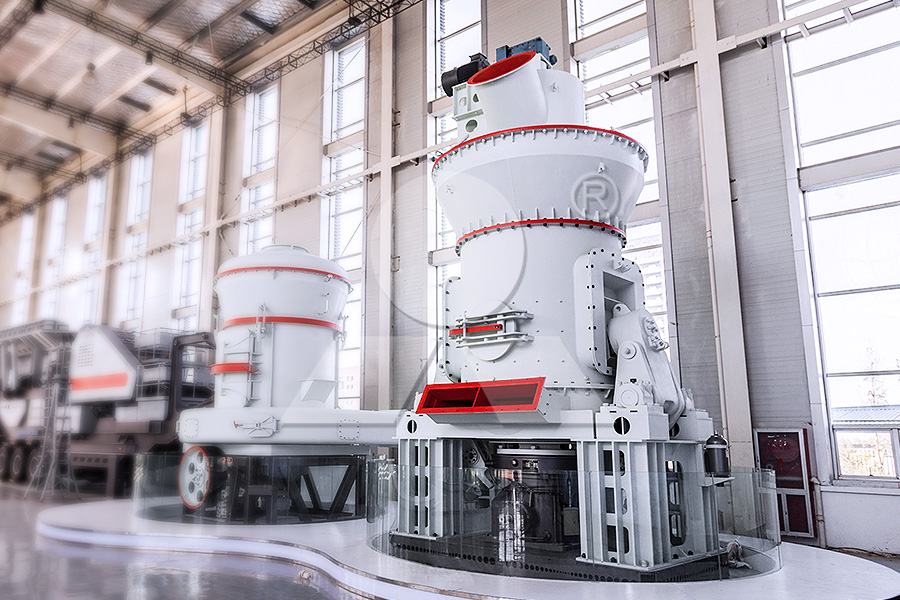

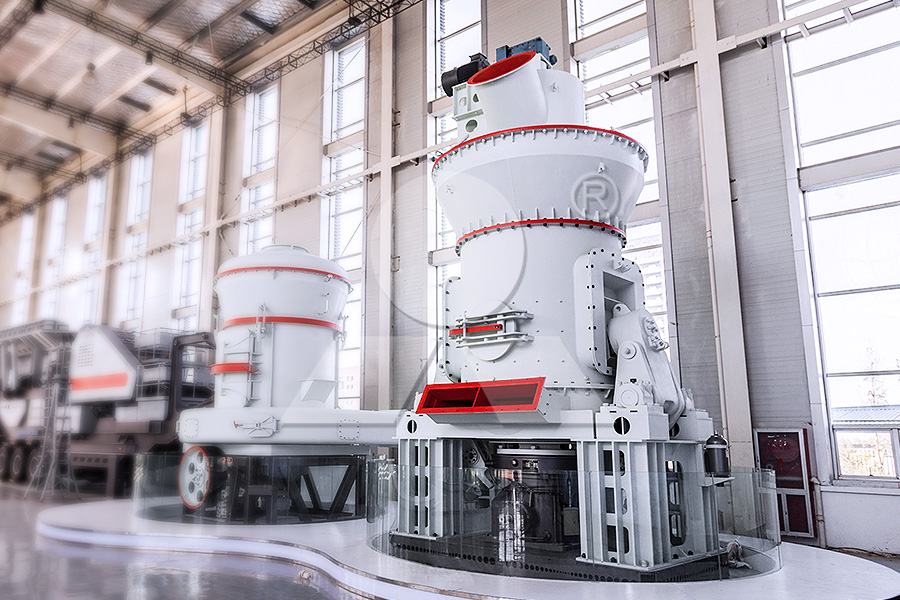

Raymond mill after a period of time, it is necessary to maintain and repair the equipment, if the maintenance and repair is not in place equipment at work will fail, bring inconvenience to our work, such as Raymond mill in the work of the phenomenon of clogging, what is the cause of this? How to solve it? The following Clirik will give you a detailed analysis.

1, too much material supply, resulting in air duct device blockage site. Duct is the main channel of the whole equipment air flow operation, it is related to the whole equipment can run smoothly. Blocked duct due to poor exhaust, will lead to the entire airflow temperature, while affecting the temperature of the motor, is the motor temperature rises, high temperature of the motor current operation is reduced, the power supply is insufficient, the equipment is not enough power to run, which affects the overall yield. The solution to this situation is mainly, adjust the feeder, properly reduce the amount of material placed, while cleaning the pipeline, remove the powder gathered in the pipeline, in addition to the duct at the valve can be properly opened up some, control the temperature of the material to ensure that the temperature of the material supplied should not be too high, the feed temperature is generally not more than 6 ℃.

2, fan blade wear, while the blade may be attached to the accumulation of powder, resulting in the blade can not run normally, affecting the final output. Solution, check the degree of wear and tear of the blade, need to be replaced in a timely manner, the blade surface attached to the powder particles to clean up, pay attention to the daily operation to check whether the blade is clean, and timely removal of powder on the blade.

3, host upper bearing oil shortage, affecting the operation of the machine. Possible problems with the quality of the oil used, oil viscosity is too large, too thick will lead to threaded pump oil can not be transported to the upper bearing, the bearing can not get timely lubrication, reduced efficiency, affecting the grinding output. Solution: Check the quality of the oil used, choose the oil products with moderate viscosity and thickness.

4, the host internal shovel knife wear, the material can not be effectively shoveled up in time, resulting in part of the material can not be ground, the amount of material grinding is reduced, resulting in a relative reduction in the final output. The solution for this situation, you can regularly check the degree of wear of the shovel knife, the need to change the shovel knife in a timely manner, and timely observation of the amount of material discharged, found that the problem is solved in a timely manner.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

Raymond mill after a period of time, it is necessary to maintain and repair the equipment, if the maintenance and repair is not in place equipment at work will fail, bring inconvenience to our work, such as Raymond mill in the work of the phenome

Raymond mill after a period of time, it is necessary to maintain and repair the equipment, if the maintenance and repair is not in place equipment at work will fail, bring inconvenience to our work, such as Raymond mill in the work of the phenomenon of clogging, what is the cause of this? How to solve it? The following Clirik will give you a detailed analysis.

1, too much material supply, resulting in air duct device blockage site. Duct is the main channel of the whole equipment air flow operation, it is related to the whole equipment can run smoothly. Blocked duct due to poor exhaust, will lead to the entire airflow temperature, while affecting the temperature of the motor, is the motor temperature rises, high temperature of the motor current operation is reduced, the power supply is insufficient, the equipment is not enough power to run, which affects the overall yield. The solution to this situation is mainly, adjust the feeder, properly reduce the amount of material placed, while cleaning the pipeline, remove the powder gathered in the pipeline, in addition to the duct at the valve can be properly opened up some, control the temperature of the material to ensure that the temperature of the material supplied should not be too high, the feed temperature is generally not more than 6 ℃.

2, fan blade wear, while the blade may be attached to the accumulation of powder, resulting in the blade can not run normally, affecting the final output. Solution, check the degree of wear and tear of the blade, need to be replaced in a timely manner, the blade surface attached to the powder particles to clean up, pay attention to the daily operation to check whether the blade is clean, and timely removal of powder on the blade.

3, host upper bearing oil shortage, affecting the operation of the machine. Possible problems with the quality of the oil used, oil viscosity is too large, too thick will lead to threaded pump oil can not be transported to the upper bearing, the bearing can not get timely lubrication, reduced efficiency, affecting the grinding output. Solution: Check the quality of the oil used, choose the oil products with moderate viscosity and thickness.

4, the host internal shovel knife wear, the material can not be effectively shoveled up in time, resulting in part of the material can not be ground, the amount of material grinding is reduced, resulting in a relative reduction in the final output. The solution for this situation, you can regularly check the degree of wear of the shovel knife, the need to change the shovel knife in a timely manner, and timely observation of the amount of material discharged, found that the problem is solved in a timely manner.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

Production price of energy-saving and environmentally friendly ultrafine grinding machine

Production price of energy-saving and environmentally friendly ultrafine grinding machine How to improve the quality change of calcium carbonate grinding machine equipment

How to improve the quality change of calcium carbonate grinding machine equipment How to select stone grinding machine equipment

How to select stone grinding machine equipment Ore Raymond Mill, Ore Superfine Mill Price

Ore Raymond Mill, Ore Superfine Mill Price 1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh

1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh Production price of energy-saving and environmentally friendly ultrafine grinding machine

Production price of energy-saving and environmentally friendly ultrafine grinding machine How to improve the quality change of calcium carbonate grinding machine equipment

How to improve the quality change of calcium carbonate grinding machine equipment How to select stone grinding machine equipment

How to select stone grinding machine equipment Ore Raymond Mill, Ore Superfine Mill Price

Ore Raymond Mill, Ore Superfine Mill Price 1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh

1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh