Mill is widely used in mining, metallurgy, chemical industry, building materials and other industries 280 kinds of materials of high-fine powder processing, suitable for Mohs hardness is not greater than 9.3 grade, humidity in 6% below the non-fl

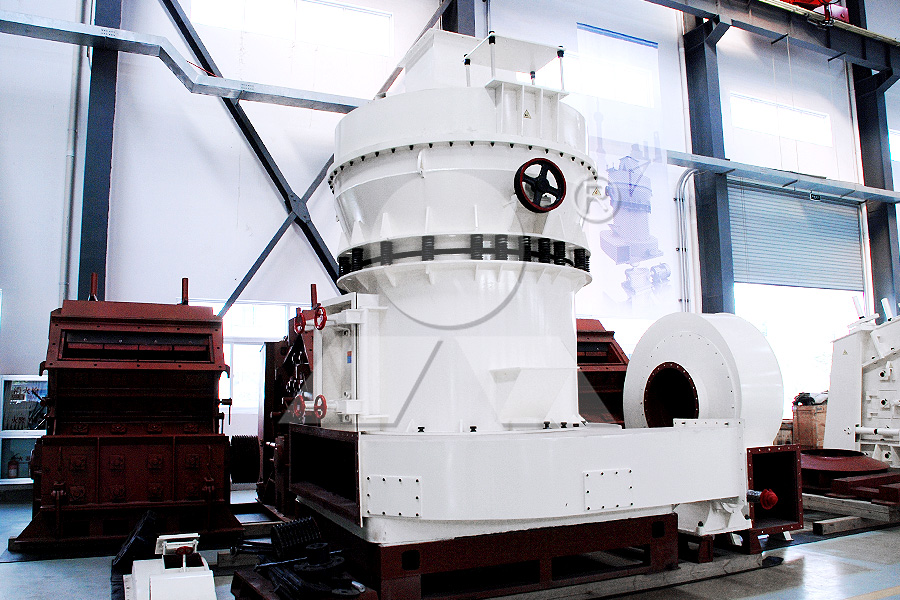

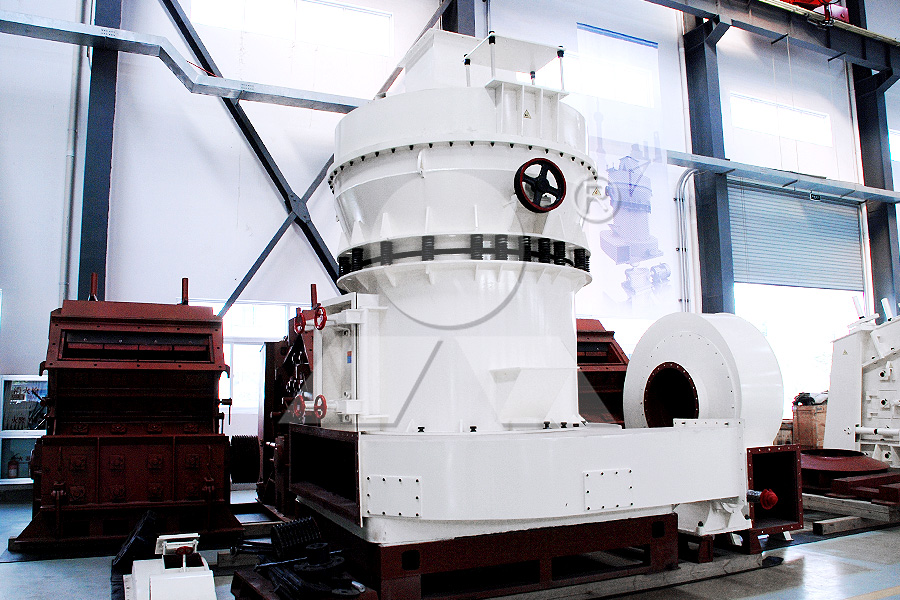

Mill is widely used in mining, metallurgy, chemical industry, building materials and other industries 280 kinds of materials of high-fine powder processing, suitable for Mohs hardness is not greater than 9.3 grade, humidity in 6% below the non-flammable and explosive materials. Such as quartz, feldspar, calcite, limestone and other materials. The equipment runs reliably, high sieve rate, long service life of wearing parts, want to keep the good performance of the machine, the correct operation and maintenance is essential, it is also to ensure that your interests and reduce the loss of the basis, then how to correctly use and maintenance of Raymond mill?

First, the correct switching steps you know?

1、Preparation work before switching on the machine

Before starting the equipment, you should check whether all the access doors are closed tightly, check whether the feed opening of the equipment is in line with the size of the feed particle size, and adjust the rotational speed of the analyser to reach the approximate finished product size requirements. In addition, it should be noted that the equipment should be started with no load, and the material should be added only after the equipment is running stably.

2, start-up steps

Starting steps: dustpan elevator - crusher - analyser - blower - Raymond Mill host, in the At the same time start the host should start the electromagnetic vibrating feeder, at this time the Raymond Mill grinding work that is the beginning.

3、Shutdown steps

Shutdown steps: first shut down the feeder to stop feeding - about one minute after stopping the host - blowing the residual powder to stop the blower - shut down the analyser.

Second, the use of the process of attention

1、Mill manufacturers will guide the installation of equipment on site, and will provide technical training to the operator, in the process of use should be a professional fixed personnel responsible for watching.

2, any part of the machine operation occurs abnormal noise, or a sudden increase in load, should immediately stop the machine to check and troubleshooting, to avoid major accidents.

3, Raymond mill according to the nature of the material is different, the degree of coarseness and fineness of the processing is different, you can adjust the top of the analyser to control the fineness.

4, located in the fan inlet pipe on the air volume control valve, generally open to a larger position, according to the fineness, the output requirements of appropriate adjustment. Located in the exhaust port exhaust pipe on the control valve, adjusted to the inlet no dust spray can be, but the air volume can not be too small, otherwise the host is easy to precipitate material in the air duct below.

Maintenance

In the working process, should regularly check the wear and tear of the wear parts of the equipment, the site also needs to have Raymond mill accessories, so as not to delay the equipment running time when it needs to be replaced. Good maintenance and timely maintenance can greatly improve the performance of the equipment, extend the service life of the equipment, so as to create more economic value for you.

Raymond mill spindle with sliding bearings or copper bushings at the upper end, the rest of the transmission part of the rolling bearings, so it must operate under good lubrication conditions, otherwise it will damage the bearings and shorten the service life, maintenance methods are as follows:

1, spindle refuelling time twice per shift, found that the oil in the oil cup no loss or loss is too slow, should immediately clean the oil channel.

2, evenly add material, add too much material will block the air duct, reduce the output, easy to burn the motor, add too little material will also reduce the output. Strictly prohibit large materials, metal blocks to join the machine, if found immediately stop and take out, otherwise it will damage the grinding roller and grinding ring or make the plum frame deformation.

3, after a period of time, the mill should be overhauled, at the same time on the grinding roller grinding ring shovel knife and other wear parts for overhaul and replacement of processing, grinding roller device before and after the use of the connecting bolts and nuts should be carefully examined to see whether there is a loosening phenomenon, lubricating oil grease whether to add enough.

4, when the remaining wall thickness of the grinding roller grinding ring is less than 10mm, has reached the end-of-life standard, should be replaced immediately.

Correct use and maintenance methods, in order to make the machine to play a better performance, to ensure the production efficiency and quality of the finished powder, so as to ensure your income.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

Mill is widely used in mining, metallurgy, chemical industry, building materials and other industries 280 kinds of materials of high-fine powder processing, suitable for Mohs hardness is not greater than 9.3 grade, humidity in 6% below the non-fl

Mill is widely used in mining, metallurgy, chemical industry, building materials and other industries 280 kinds of materials of high-fine powder processing, suitable for Mohs hardness is not greater than 9.3 grade, humidity in 6% below the non-flammable and explosive materials. Such as quartz, feldspar, calcite, limestone and other materials. The equipment runs reliably, high sieve rate, long service life of wearing parts, want to keep the good performance of the machine, the correct operation and maintenance is essential, it is also to ensure that your interests and reduce the loss of the basis, then how to correctly use and maintenance of Raymond mill?

First, the correct switching steps you know?

1、Preparation work before switching on the machine

Before starting the equipment, you should check whether all the access doors are closed tightly, check whether the feed opening of the equipment is in line with the size of the feed particle size, and adjust the rotational speed of the analyser to reach the approximate finished product size requirements. In addition, it should be noted that the equipment should be started with no load, and the material should be added only after the equipment is running stably.

2, start-up steps

Starting steps: dustpan elevator - crusher - analyser - blower - Raymond Mill host, in the At the same time start the host should start the electromagnetic vibrating feeder, at this time the Raymond Mill grinding work that is the beginning.

3、Shutdown steps

Shutdown steps: first shut down the feeder to stop feeding - about one minute after stopping the host - blowing the residual powder to stop the blower - shut down the analyser.

Second, the use of the process of attention

1、Mill manufacturers will guide the installation of equipment on site, and will provide technical training to the operator, in the process of use should be a professional fixed personnel responsible for watching.

2, any part of the machine operation occurs abnormal noise, or a sudden increase in load, should immediately stop the machine to check and troubleshooting, to avoid major accidents.

3, Raymond mill according to the nature of the material is different, the degree of coarseness and fineness of the processing is different, you can adjust the top of the analyser to control the fineness.

4, located in the fan inlet pipe on the air volume control valve, generally open to a larger position, according to the fineness, the output requirements of appropriate adjustment. Located in the exhaust port exhaust pipe on the control valve, adjusted to the inlet no dust spray can be, but the air volume can not be too small, otherwise the host is easy to precipitate material in the air duct below.

Maintenance

In the working process, should regularly check the wear and tear of the wear parts of the equipment, the site also needs to have Raymond mill accessories, so as not to delay the equipment running time when it needs to be replaced. Good maintenance and timely maintenance can greatly improve the performance of the equipment, extend the service life of the equipment, so as to create more economic value for you.

Raymond mill spindle with sliding bearings or copper bushings at the upper end, the rest of the transmission part of the rolling bearings, so it must operate under good lubrication conditions, otherwise it will damage the bearings and shorten the service life, maintenance methods are as follows:

1, spindle refuelling time twice per shift, found that the oil in the oil cup no loss or loss is too slow, should immediately clean the oil channel.

2, evenly add material, add too much material will block the air duct, reduce the output, easy to burn the motor, add too little material will also reduce the output. Strictly prohibit large materials, metal blocks to join the machine, if found immediately stop and take out, otherwise it will damage the grinding roller and grinding ring or make the plum frame deformation.

3, after a period of time, the mill should be overhauled, at the same time on the grinding roller grinding ring shovel knife and other wear parts for overhaul and replacement of processing, grinding roller device before and after the use of the connecting bolts and nuts should be carefully examined to see whether there is a loosening phenomenon, lubricating oil grease whether to add enough.

4, when the remaining wall thickness of the grinding roller grinding ring is less than 10mm, has reached the end-of-life standard, should be replaced immediately.

Correct use and maintenance methods, in order to make the machine to play a better performance, to ensure the production efficiency and quality of the finished powder, so as to ensure your income.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher