Although impact crusher and cone crusher are secondary crushing equipment, they are both placed on the coarse crusher. It was previously used to complete the secondary fine crushing of sand and gravel, but if you look closely there are still big differ

Although impact crusher and cone crusher are secondary crushing equipment, they are both placed on the coarse crusher. It was previously used to complete the secondary fine crushing of sand and gravel, but if you look closely there are still big differences. The difference between the two is introduced below.

Learn the difference between impact crusher and cone crusher. Click for consultation

1. Crusher Principle Comparison

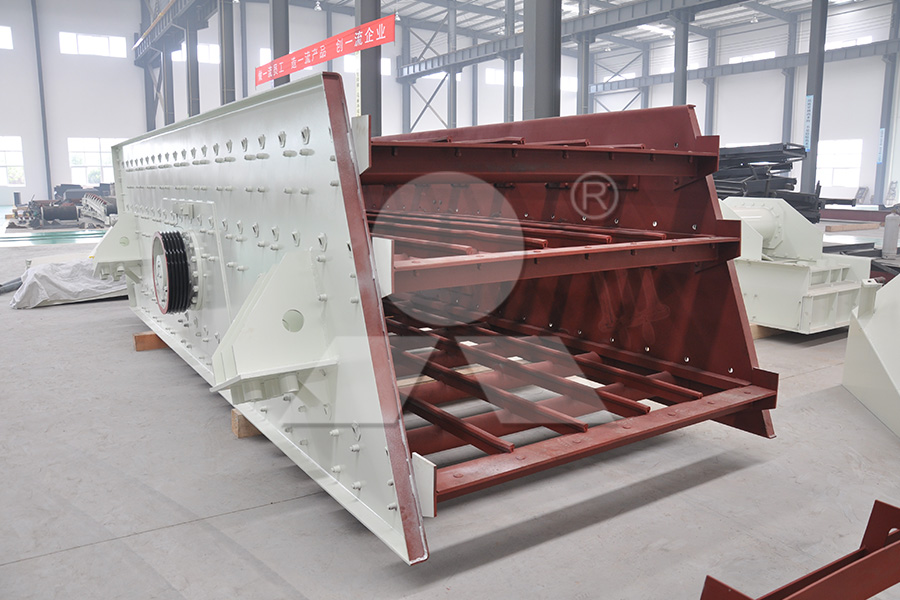

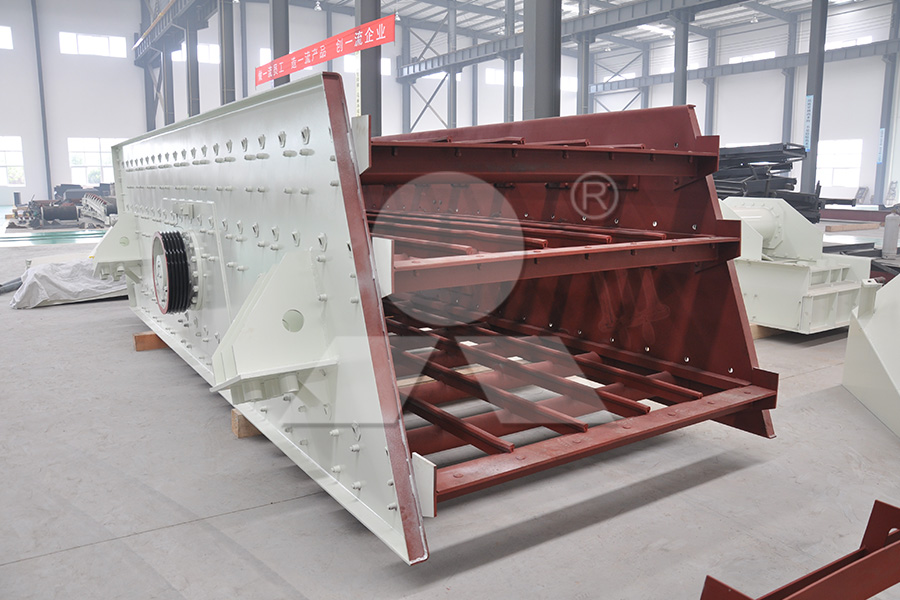

1. Impact crusher: The material is crushed by the collision and friction between the hammer and the impact plate, and has a micro-shaping effect. The material processed by the impact crusher has uniform particle size, low needle-like content and optimized gradation. The finished product has good size, few needle-like particles, and significantly improved overall quality.

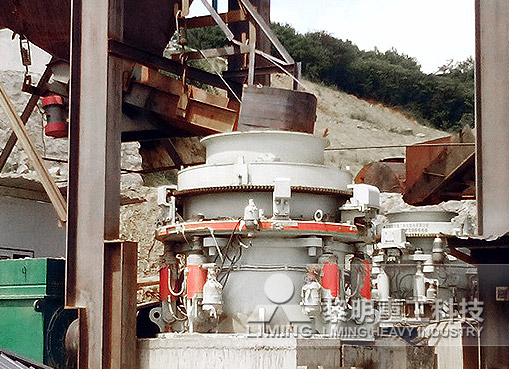

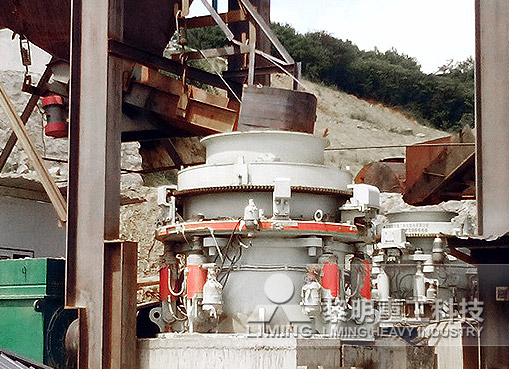

2. Cone crusher: This equipment is an innovation of the traditional cone crusher system, and adopts the layered crushing principle to achieve material crushing. Although its crushing effect is slightly inferior to that of the impact crusher and the particle shape is not ideal, it is still widely used in the market due to its low energy consumption, high output and production stability.

2. Crusher Raw Materials Comparison

Stone raw materials of different specifications have different hardness characteristics, so impact crushers and cone crushers also have different characteristics when processing stone crushing.

The impact crusher is suitable for crushing soft stones such as limestone, dolomite, weathered rock, etc. The cone crusher is more suitable for crushing high-hardness stone raw materials such as river pebbles, granite, quartz stone, basalt, etc.

Pebbles are harder than limestone and shale, so wear resistance needs to be considered when selecting processing equipment. It is recommended to use a cone crusher. Although the particle shape of its finished product is slightly inferior to that of an impact crusher, its processing capacity is strong. When crushing high-hardness pebbles, the cone crusher has high wear resistance, small wear and tear, and large output, which can bring significant economic benefits to investors. Therefore, for hard materials such as pebbles, cone crusher is a better choice.

Previous: SMP Crusher

Next: SMP Crusher

Although impact crusher and cone crusher are secondary crushing equipment, they are both placed on the coarse crusher. It was previously used to complete the secondary fine crushing of sand and gravel, but if you look closely there are still big differ

Although impact crusher and cone crusher are secondary crushing equipment, they are both placed on the coarse crusher. It was previously used to complete the secondary fine crushing of sand and gravel, but if you look closely there are still big differences. The difference between the two is introduced below.

Learn the difference between impact crusher and cone crusher. Click for consultation

1. Crusher Principle Comparison

1. Impact crusher: The material is crushed by the collision and friction between the hammer and the impact plate, and has a micro-shaping effect. The material processed by the impact crusher has uniform particle size, low needle-like content and optimized gradation. The finished product has good size, few needle-like particles, and significantly improved overall quality.

2. Cone crusher: This equipment is an innovation of the traditional cone crusher system, and adopts the layered crushing principle to achieve material crushing. Although its crushing effect is slightly inferior to that of the impact crusher and the particle shape is not ideal, it is still widely used in the market due to its low energy consumption, high output and production stability.

2. Crusher Raw Materials Comparison

Stone raw materials of different specifications have different hardness characteristics, so impact crushers and cone crushers also have different characteristics when processing stone crushing.

The impact crusher is suitable for crushing soft stones such as limestone, dolomite, weathered rock, etc. The cone crusher is more suitable for crushing high-hardness stone raw materials such as river pebbles, granite, quartz stone, basalt, etc.

Pebbles are harder than limestone and shale, so wear resistance needs to be considered when selecting processing equipment. It is recommended to use a cone crusher. Although the particle shape of its finished product is slightly inferior to that of an impact crusher, its processing capacity is strong. When crushing high-hardness pebbles, the cone crusher has high wear resistance, small wear and tear, and large output, which can bring significant economic benefits to investors. Therefore, for hard materials such as pebbles, cone crusher is a better choice.

Previous: SMP Crusher

Next: SMP Crusher

What industries are 300 tons per hour mobile crushers suitable for?

What industries are 300 tons per hour mobile crushers suitable for? What equipment is there for crushing stones? How much does one cost?

What equipment is there for crushing stones? How much does one cost? What are the functions of the main wear-resistant parts of the jaw crusher?

What are the functions of the main wear-resistant parts of the jaw crusher? Sand and gravel equipment manufacturers teach you how to buy a good cone crusher

Sand and gravel equipment manufacturers teach you how to buy a good cone crusher What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running?

What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running? What industries are 300 tons per hour mobile crushers suitable for?

What industries are 300 tons per hour mobile crushers suitable for? What equipment is there for crushing stones? How much does one cost?

What equipment is there for crushing stones? How much does one cost? What are the functions of the main wear-resistant parts of the jaw crusher?

What are the functions of the main wear-resistant parts of the jaw crusher? Sand and gravel equipment manufacturers teach you how to buy a good cone crusher

Sand and gravel equipment manufacturers teach you how to buy a good cone crusher What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running?

What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running?