The following are the main types of equipment for crushing stones:Click here to learn about stone crushing equipment1. Jaw crusherThe C6X jaw crusher has been optimized in structure to achieve efficient crushing and hig

The following are the main types of equipment for crushing stones:

Click here to learn about stone crushing equipment

1. Jaw crusher

The C6X jaw crusher has been optimized in structure to achieve efficient crushing and higher return on investment. It uses centralized grease lubrication, and can be selected manually or automatically to simplify maintenance. The double wedge adjusts the discharge port, making operation more convenient. These improvements make the equipment more efficient at the same power consumption and the work site cleaner.

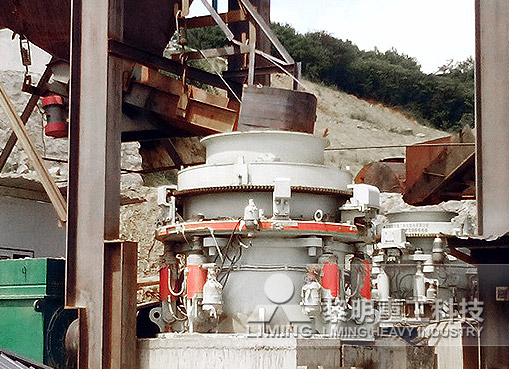

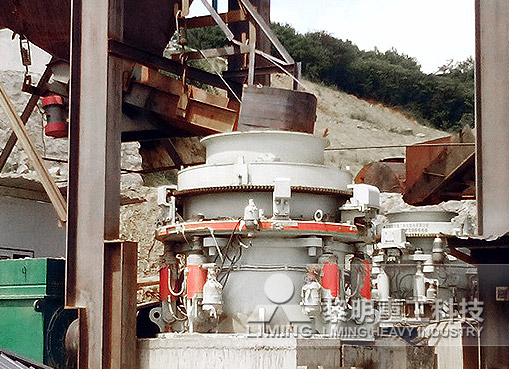

2. Cone crusher

The cone crusher launched by Shibang Group is designed for medium and high hardness rocks. The integrated control system simplifies operation and improves safety performance. It adopts the principle of laminated crushing, with high efficiency and low wear. The finished product is in a cubic shape and has rich fine particle sizes. The multi-cavity configuration can be converted by replacing a small number of parts to meet the needs of medium and fine crushing, realizing the multi-functional application of the equipment.

3. Impact crusher

The CI5X series impact crusher is equipped with a large moment of inertia, high-precision heavy-duty rotor and high-quality bearings to ensure that the material is fully accelerated and crushed to achieve a higher crushing ratio. Its multifunctional fully hydraulic operating system can be adjusted accurately and quickly, which is convenient for maintenance and replacement of parts and adjustment of the particle size of the discharge material, effectively saving labor and time costs.

4. Vertical shaft impact crusher

The VSI6X vertical shaft impact crusher optimizes the crushing cavity, adopts the "stone hitting stone" and "stone hitting iron" crushing methods, and specially designs the material lining and impact block structure to improve the crushing efficiency. At the same time, it is equipped with a simple lifting device to reduce the difficulty of maintaining the impeller and bearing cylinder, and no additional large lifting equipment is required.

How much does a stone crushing equipment cost?

The specific price of a stone crushing equipment should also be combined with the actual selection. Due to different equipment models, the cost required for manufacturing is also different. In addition, there are many large crusher manufacturers on the market, with different business models, processes, and selected raw materials. Generally, one equipment ranges from hundreds of thousands to millions.

Previous: SMP Crusher

Next: SMP Crusher

The following are the main types of equipment for crushing stones:Click here to learn about stone crushing equipment1. Jaw crusherThe C6X jaw crusher has been optimized in structure to achieve efficient crushing and hig

The following are the main types of equipment for crushing stones:

Click here to learn about stone crushing equipment

1. Jaw crusher

The C6X jaw crusher has been optimized in structure to achieve efficient crushing and higher return on investment. It uses centralized grease lubrication, and can be selected manually or automatically to simplify maintenance. The double wedge adjusts the discharge port, making operation more convenient. These improvements make the equipment more efficient at the same power consumption and the work site cleaner.

2. Cone crusher

The cone crusher launched by Shibang Group is designed for medium and high hardness rocks. The integrated control system simplifies operation and improves safety performance. It adopts the principle of laminated crushing, with high efficiency and low wear. The finished product is in a cubic shape and has rich fine particle sizes. The multi-cavity configuration can be converted by replacing a small number of parts to meet the needs of medium and fine crushing, realizing the multi-functional application of the equipment.

3. Impact crusher

The CI5X series impact crusher is equipped with a large moment of inertia, high-precision heavy-duty rotor and high-quality bearings to ensure that the material is fully accelerated and crushed to achieve a higher crushing ratio. Its multifunctional fully hydraulic operating system can be adjusted accurately and quickly, which is convenient for maintenance and replacement of parts and adjustment of the particle size of the discharge material, effectively saving labor and time costs.

4. Vertical shaft impact crusher

The VSI6X vertical shaft impact crusher optimizes the crushing cavity, adopts the "stone hitting stone" and "stone hitting iron" crushing methods, and specially designs the material lining and impact block structure to improve the crushing efficiency. At the same time, it is equipped with a simple lifting device to reduce the difficulty of maintaining the impeller and bearing cylinder, and no additional large lifting equipment is required.

How much does a stone crushing equipment cost?

The specific price of a stone crushing equipment should also be combined with the actual selection. Due to different equipment models, the cost required for manufacturing is also different. In addition, there are many large crusher manufacturers on the market, with different business models, processes, and selected raw materials. Generally, one equipment ranges from hundreds of thousands to millions.

Previous: SMP Crusher

Next: SMP Crusher

What are the functions of the main wear-resistant parts of the jaw crusher?

What are the functions of the main wear-resistant parts of the jaw crusher? Sand and gravel equipment manufacturers teach you how to buy a good cone crusher

Sand and gravel equipment manufacturers teach you how to buy a good cone crusher What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running?

What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running? Effective measures to reduce wear of crushing equipment

Effective measures to reduce wear of crushing equipment How to correctly configure the stone production line in the quarry

How to correctly configure the stone production line in the quarry What are the functions of the main wear-resistant parts of the jaw crusher?

What are the functions of the main wear-resistant parts of the jaw crusher? Sand and gravel equipment manufacturers teach you how to buy a good cone crusher

Sand and gravel equipment manufacturers teach you how to buy a good cone crusher What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running?

What are the reasons for the failure of lubrication of the sand making machine after the 300 tons per hour sand and gravel production line is running? Effective measures to reduce wear of crushing equipment

Effective measures to reduce wear of crushing equipment How to correctly configure the stone production line in the quarry

How to correctly configure the stone production line in the quarry