Material Introduction: Iron is the most widely used and consumed metal, mainly used in the iron and steel industry, the customer is located in Anshan, Liaoning, which is the city with the most iron ore content, this production line is designed for the

Material Introduction: Iron is the most widely used and consumed metal, mainly used in the iron and steel industry, the customer is located in Anshan, Liaoning, which is the city with the most iron ore content, this production line is designed for the customer by us with the combination of the nature of the customer's iron ore, the workplace and sales channels, etc., and the production capacity and product quality of this iron ore production line can meet the customer's requirements.

Iron ore material production situation:

Liaoning Anshan as the largest iron ore content of the city, where there is a lot of iron ore beneficiation, combined with the local conditions we designed this iron ore production line for the customer, the work process is divided into crushing, grinding, magnetic separation and drying.

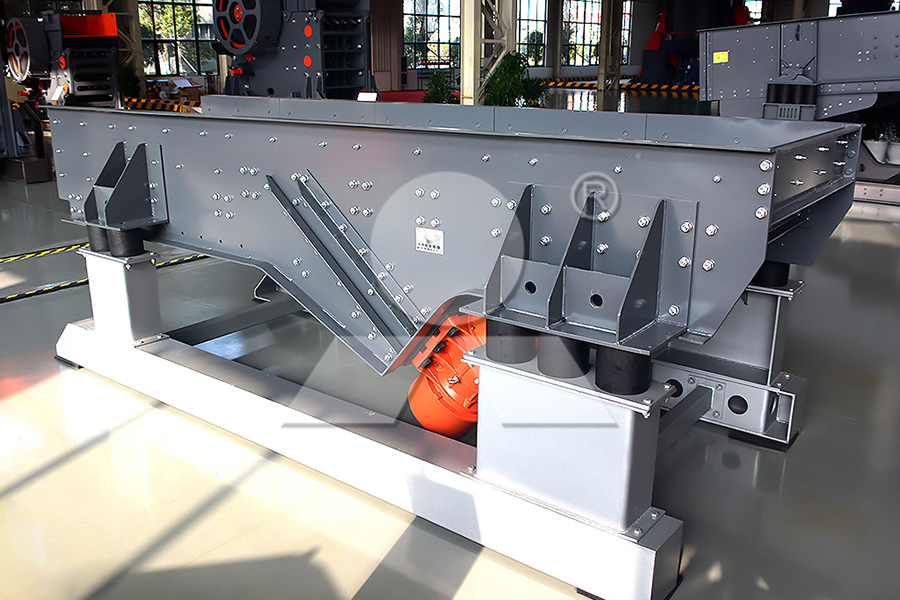

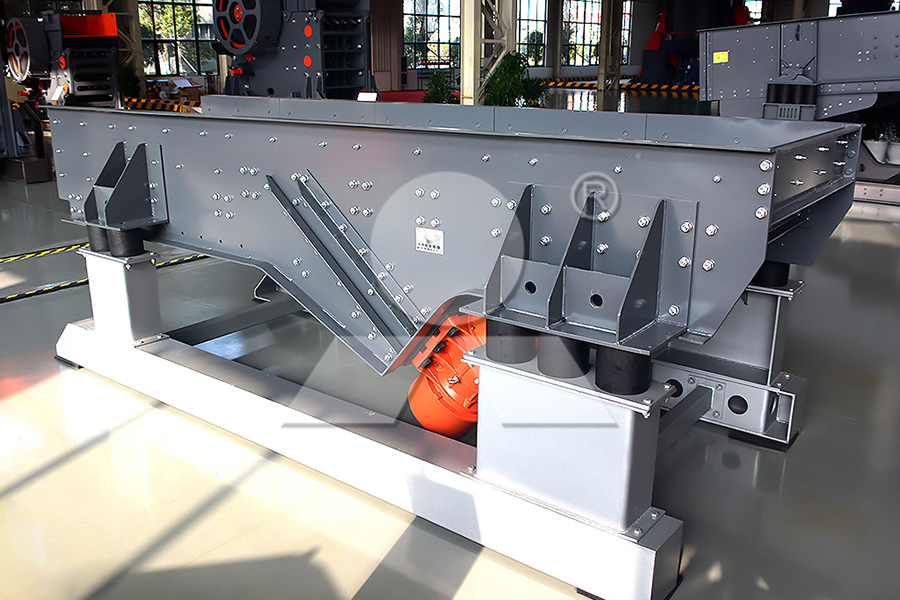

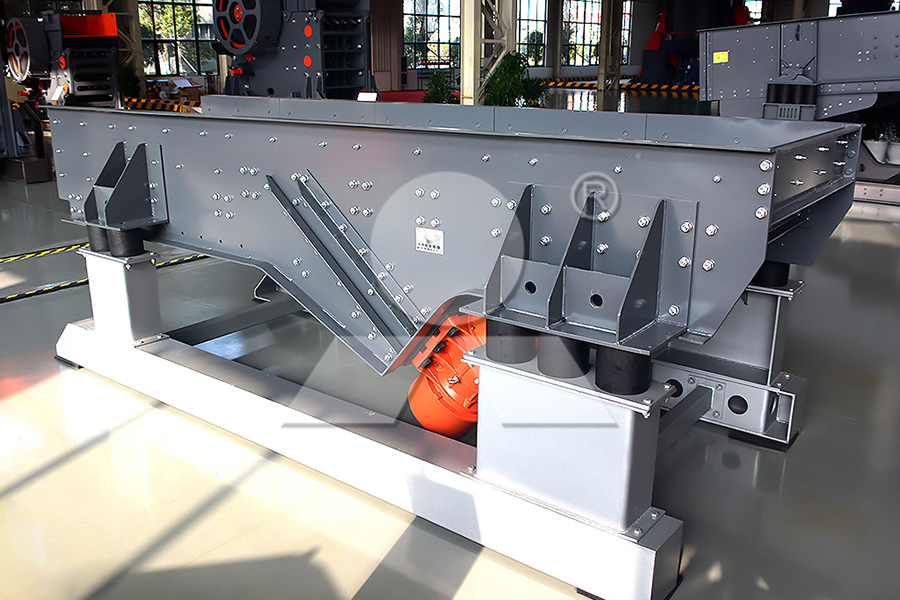

The approximate process is that the iron ore is firstly crushed by jaw crusher, and then sent to cone crusher for secondary crushing, after crushing, the qualified iron ore is screened out by vibrating screen and sent to ball mill for grinding, the unqualified is returned to cone crusher to continue crushing, after grinding, the iron ore powder is screened by classifier, the unqualified is returned to ball mill to continue crushing, and the qualified enters into the magnetic separator for rougher and finer selection, in the sub-selection link, we choose two sets of In the secondary separation, we choose two magnetic separators to screen the iron ore successively, so that the screened iron ore has high iron content and good quality.

Advantages of production line:

1、Little wear and tear of equipments: Because the cone crusher is used in the second crushing, the self-protection device of the cone crusher will discharge the materials with excessive hardness out of the whole production line, so as to ensure the subsequent equipments work normally and reduce their wear and tear;

2、Stable operation: the whole production line is matching design, so each piece of equipment can send back its best performance, to ensure the output of the production line, and produce little noise and dust pollution;

3、Good product quality: different magnetic separators are chosen to magnetically select the iron powder, which improves the content of iron powder in the product.

Customer Evaluation:

Henan Liming Heavy Industry is already the second time to cooperate with us, the previous mineral processing production line is also ordered from them, their production line produces products with high iron content, and the sales are very good in the market, so we expanded the production and ordered another set, the second production line is higher than the first production line. The second production line has higher output than the first one. Compared with the first production line, the quality and performance are better, and the after-sales service is as attentive as ever. We hope that Henan Liming Heavy Industry can keep such quality as always, and we are looking forward to cooperating with Henan Liming Heavy Industry all the time.

Previous: SMP Crusher

Next: SMP Crusher

Material Introduction: Iron is the most widely used and consumed metal, mainly used in the iron and steel industry, the customer is located in Anshan, Liaoning, which is the city with the most iron ore content, this production line is designed for the

Material Introduction: Iron is the most widely used and consumed metal, mainly used in the iron and steel industry, the customer is located in Anshan, Liaoning, which is the city with the most iron ore content, this production line is designed for the customer by us with the combination of the nature of the customer's iron ore, the workplace and sales channels, etc., and the production capacity and product quality of this iron ore production line can meet the customer's requirements.

Iron ore material production situation:

Liaoning Anshan as the largest iron ore content of the city, where there is a lot of iron ore beneficiation, combined with the local conditions we designed this iron ore production line for the customer, the work process is divided into crushing, grinding, magnetic separation and drying.

The approximate process is that the iron ore is firstly crushed by jaw crusher, and then sent to cone crusher for secondary crushing, after crushing, the qualified iron ore is screened out by vibrating screen and sent to ball mill for grinding, the unqualified is returned to cone crusher to continue crushing, after grinding, the iron ore powder is screened by classifier, the unqualified is returned to ball mill to continue crushing, and the qualified enters into the magnetic separator for rougher and finer selection, in the sub-selection link, we choose two sets of In the secondary separation, we choose two magnetic separators to screen the iron ore successively, so that the screened iron ore has high iron content and good quality.

Advantages of production line:

1、Little wear and tear of equipments: Because the cone crusher is used in the second crushing, the self-protection device of the cone crusher will discharge the materials with excessive hardness out of the whole production line, so as to ensure the subsequent equipments work normally and reduce their wear and tear;

2、Stable operation: the whole production line is matching design, so each piece of equipment can send back its best performance, to ensure the output of the production line, and produce little noise and dust pollution;

3、Good product quality: different magnetic separators are chosen to magnetically select the iron powder, which improves the content of iron powder in the product.

Customer Evaluation:

Henan Liming Heavy Industry is already the second time to cooperate with us, the previous mineral processing production line is also ordered from them, their production line produces products with high iron content, and the sales are very good in the market, so we expanded the production and ordered another set, the second production line is higher than the first production line. The second production line has higher output than the first one. Compared with the first production line, the quality and performance are better, and the after-sales service is as attentive as ever. We hope that Henan Liming Heavy Industry can keep such quality as always, and we are looking forward to cooperating with Henan Liming Heavy Industry all the time.

Previous: SMP Crusher

Next: SMP Crusher