The lead-zinc ore processing line in Xilin, Northeast China has a daily capacity of 5,000 tonnes, which adopts HPT cone crusher and jaw crusher to achieve high efficiency crushing, with scientific process, stable operation, cost saving, improved effici

The lead-zinc ore processing line in Xilin, Northeast China has a daily capacity of 5,000 tonnes, which adopts HPT cone crusher and jaw crusher to achieve high efficiency crushing, with scientific process, stable operation, cost saving, improved efficiency and product quality to meet the market demand, and has become a model in the industry.

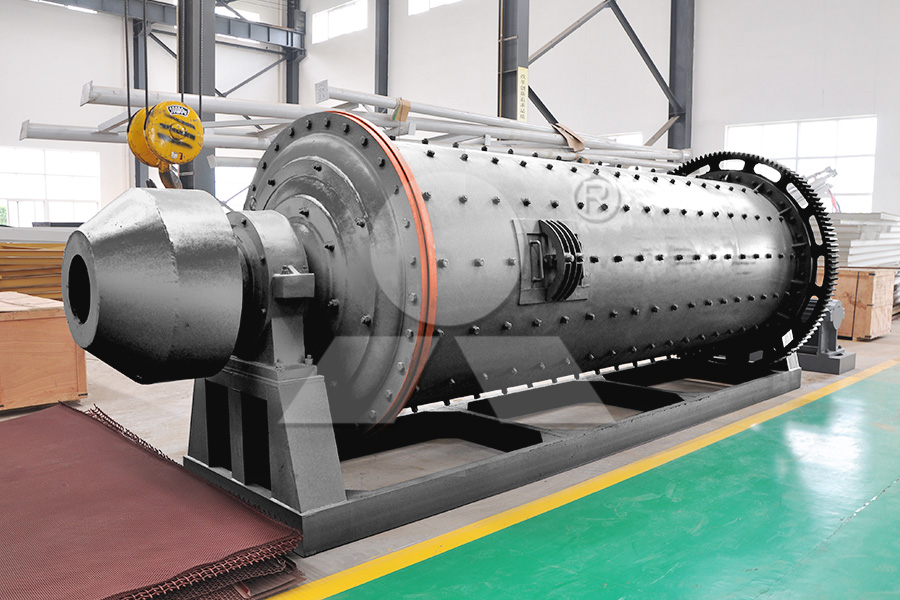

In the field of metal smelting, the processing of lead-zinc ore is crucial. The lead-zinc ore processing line located in Xilin, Northeast China, with a daily processing capacity of 5,000 tonnes, demonstrates excellent productivity and advanced process configuration.

Equipment Configuration

In order to achieve a highly efficient crushing process, the NEXILIN lead-zinc ore processing line adopts the following equipment configuration:

Core equipment at crushing stage

In the crushing stage of lead-zinc ore, the process is usually divided into two parts: crushing and screening. Its main purpose is to crush the large lead-zinc ore to the appropriate particle size, in order to achieve the initial dissociation between the minerals, so as to lay a solid foundation for the subsequent beneficiation process.

1、Primary crushing: The lead-zinc ore is roughly crushed by jaw crusher. With its powerful crushing capacity and stable performance, the jaw crusher ensures efficient crushing of large ores.

2.Secondary Crushing: The roughly crushed material is conveyed into the HPT Cone Crusher for medium and fine crushing. the HPT Cone Crusher further refines the ore to the desired size with its high efficiency and stable crushing capacity.

3、Screening: The materials after medium and fine crushing are screened by the screening equipment to ensure that the size meets the requirements of the next stage of processing, while the unqualified materials are returned to the cone crusher for further crushing.

Advantages of production line

Northeast Xilin lead-zinc ore processing production line achieves efficient production and high-quality product output by virtue of its advanced equipment configuration and scientific process flow. Below are a few of the significant advantages of this production line:

High-efficiency crushing: The combination of HPT series cone crusher and jaw crusher ensures efficient crushing and particle size control of the ore.

Stable operation: The high performance and stability of the equipment ensures continuous and efficient operation of the production line.

Cost saving: Optimised crushing and screening process reduces unnecessary reworking of materials and saves production costs.

Customer Feedback

Since its commissioning, the lead-zinc ore processing line in Xilin, Northeast China, has been widely praised. Customers say that the production line not only improves production efficiency, but also significantly improves product quality and meets market demand.

Conclusion

Northeast Xilin lead-zinc ore processing line, with its high efficiency and stable production capacity, has set a new benchmark for lead-zinc ore processing. Through scientific equipment configuration and optimised process flow, the production line has demonstrated strong competitiveness in the field of metal smelting and become a model in the industry.

Previous: SMP Crusher

Next: SMP Crusher

The lead-zinc ore processing line in Xilin, Northeast China has a daily capacity of 5,000 tonnes, which adopts HPT cone crusher and jaw crusher to achieve high efficiency crushing, with scientific process, stable operation, cost saving, improved effici

The lead-zinc ore processing line in Xilin, Northeast China has a daily capacity of 5,000 tonnes, which adopts HPT cone crusher and jaw crusher to achieve high efficiency crushing, with scientific process, stable operation, cost saving, improved efficiency and product quality to meet the market demand, and has become a model in the industry.

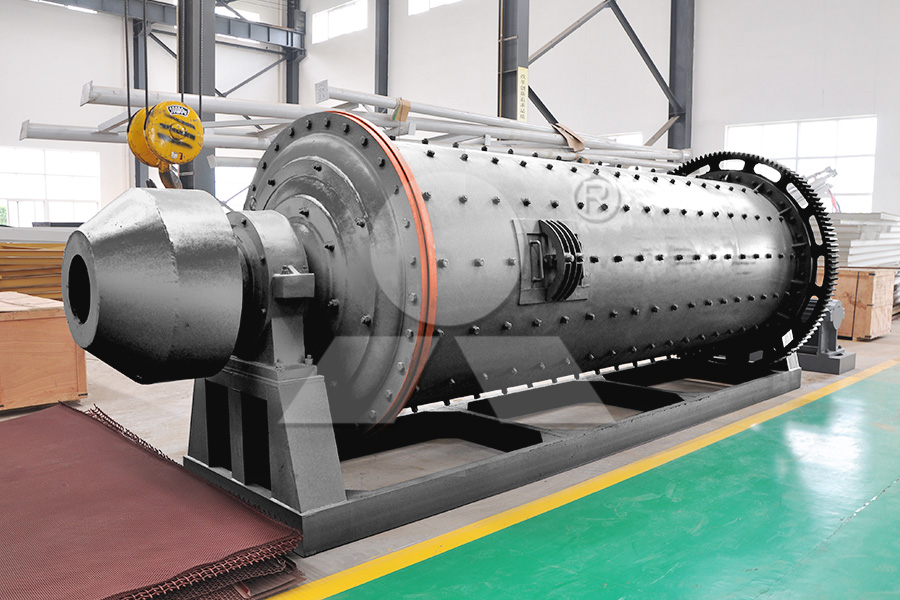

In the field of metal smelting, the processing of lead-zinc ore is crucial. The lead-zinc ore processing line located in Xilin, Northeast China, with a daily processing capacity of 5,000 tonnes, demonstrates excellent productivity and advanced process configuration.

Equipment Configuration

In order to achieve a highly efficient crushing process, the NEXILIN lead-zinc ore processing line adopts the following equipment configuration:

Core equipment at crushing stage

In the crushing stage of lead-zinc ore, the process is usually divided into two parts: crushing and screening. Its main purpose is to crush the large lead-zinc ore to the appropriate particle size, in order to achieve the initial dissociation between the minerals, so as to lay a solid foundation for the subsequent beneficiation process.

1、Primary crushing: The lead-zinc ore is roughly crushed by jaw crusher. With its powerful crushing capacity and stable performance, the jaw crusher ensures efficient crushing of large ores.

2.Secondary Crushing: The roughly crushed material is conveyed into the HPT Cone Crusher for medium and fine crushing. the HPT Cone Crusher further refines the ore to the desired size with its high efficiency and stable crushing capacity.

3、Screening: The materials after medium and fine crushing are screened by the screening equipment to ensure that the size meets the requirements of the next stage of processing, while the unqualified materials are returned to the cone crusher for further crushing.

Advantages of production line

Northeast Xilin lead-zinc ore processing production line achieves efficient production and high-quality product output by virtue of its advanced equipment configuration and scientific process flow. Below are a few of the significant advantages of this production line:

High-efficiency crushing: The combination of HPT series cone crusher and jaw crusher ensures efficient crushing and particle size control of the ore.

Stable operation: The high performance and stability of the equipment ensures continuous and efficient operation of the production line.

Cost saving: Optimised crushing and screening process reduces unnecessary reworking of materials and saves production costs.

Customer Feedback

Since its commissioning, the lead-zinc ore processing line in Xilin, Northeast China, has been widely praised. Customers say that the production line not only improves production efficiency, but also significantly improves product quality and meets market demand.

Conclusion

Northeast Xilin lead-zinc ore processing line, with its high efficiency and stable production capacity, has set a new benchmark for lead-zinc ore processing. Through scientific equipment configuration and optimised process flow, the production line has demonstrated strong competitiveness in the field of metal smelting and become a model in the industry.

Previous: SMP Crusher

Next: SMP Crusher

Manganese ore crushing treatment process and equipment application

Manganese ore crushing treatment process and equipment application What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine How to configure 300 tonnes per hour manganese ore crushing production line

How to configure 300 tonnes per hour manganese ore crushing production line Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project

Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project Manganese ore crushing treatment process and equipment application

Manganese ore crushing treatment process and equipment application What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine What are the influencing factors of construction waste crusher and how much is construction waste crusher machine

What are the influencing factors of construction waste crusher and how much is construction waste crusher machine How to configure 300 tonnes per hour manganese ore crushing production line

How to configure 300 tonnes per hour manganese ore crushing production line Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project

Case of Inner Mongolia 12 million tonnes per annum iron ore treatment project