Limestone as the 1 common ore, the main component is calcium carbonate (CaCO), Mohs hardness of 3, belongs to soft rock. It has the characteristics of chemical resistance, acid resistance, and is not easy to corrode, and is widely used in many fields s

Limestone as the 1 common ore, the main component is calcium carbonate (CaCO), Mohs hardness of 3, belongs to soft rock. It has the characteristics of chemical resistance, acid resistance, and is not easy to corrode, and is widely used in many fields such as architecture, glass, paint, and desiccant. In order to meet the growing demand for construction and infrastructure, the efficient operation of limestone sand production lines has become an important issue in the mining industry. The following is an introduction to how to convert this valuable resource into high-quality sand and gravel materials through a limestone sand production line.

Limestone sand production line price

Process flow of limestone crushing production line

Limestone sand production line mainly includes four stages: coarse crushing, medium crushing, sand making and screening.

The first stage: coarse crushing

After the limestone ore is mined from the mountain, the block material is transported to the silo by blasting operation. Through the vibrating feeder, the stone is evenly fed into the jaw crusher for preliminary coarse crushing treatment. The jaw crusher can effectively crush large pieces of stone into medium particle size, ready for subsequent processing.

The second stage: broken

The coarsely crushed stones are screened by a vibrating screen, and the screened medium granules are transported to the impact crusher through a belt conveyor for further medium crushing treatment. The crushed stones are screened by a vibrating screen again, and the stones that meet the customer's particle size requirements are sent to the finished product pile, and those that do not meet the requirements are returned to the impact crusher to continue crushing, forming a closed cycle.

The third stage: sand making

The crushed stone is transported to the sand making machine through the belt conveyor. The sand making machine further breaks and shapes the stone to produce high-quality sand. According to different needs, you can choose a double-rotor sand making machine, an impact sand making machine or a vertical shaft sand making machine to meet specific sand making requirements.

The fourth stage: screening

The finely crushed and reshaped sand is screened for coarse sand, medium sand and fine sand through a circular vibration screen. In order to meet the strict requirements of sand powder content, sand washing machine can be equipped after screening. The sand washing machine can effectively remove the fine powder in the sand, improve the purity of the sand, and recycle the sewage through the fine sand recovery device, reduce the environmental pollution and improve the sand production.

Equipment configuration of limestone sand production line

The complete limestone sand production line includes the following main equipment:

Vibrating feeder: responsible for evenly feeding the stone into the crusher cavity.

Jaw crusher: used for preliminary crushing, crushing large pieces of stone into medium particle size.

Impact crusher: used for medium crushing to further crush medium-sized stone.

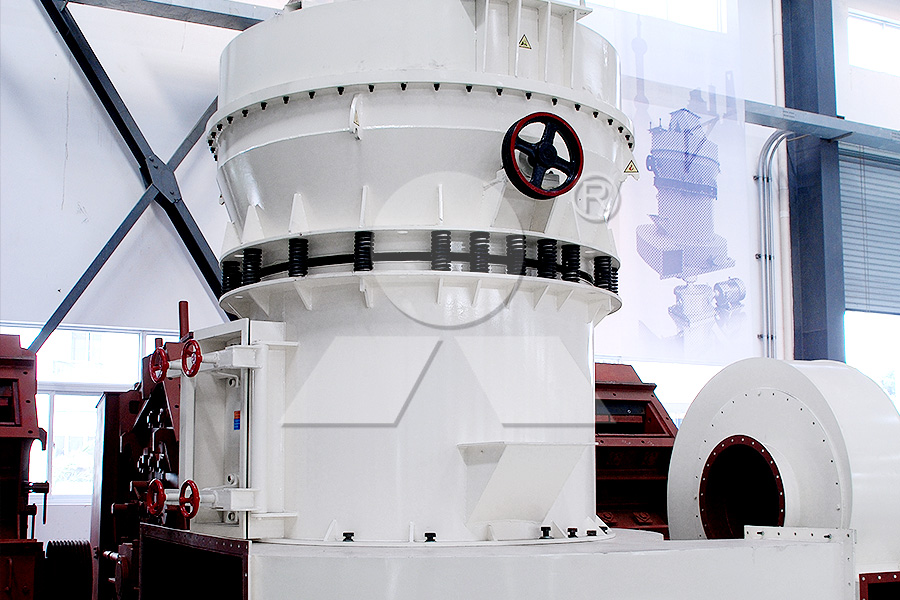

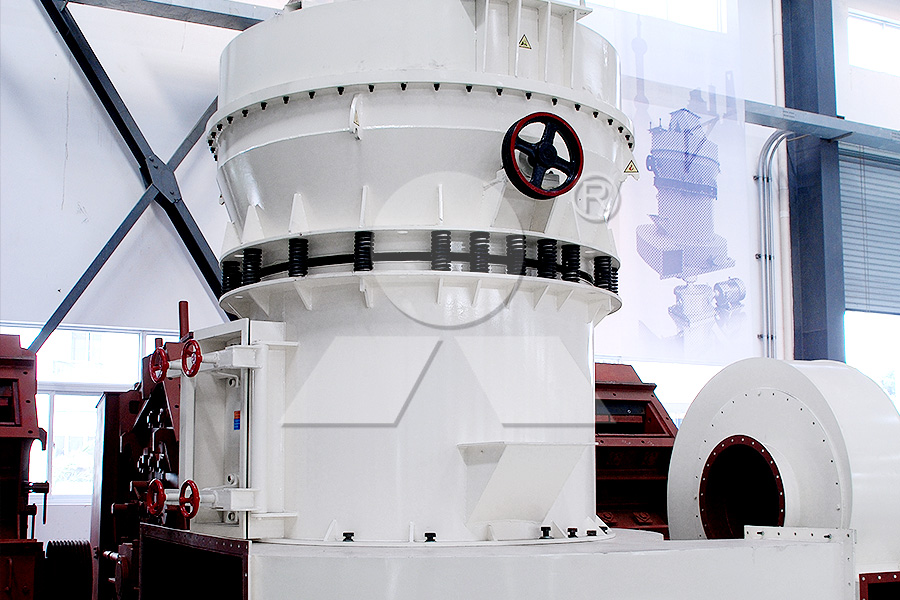

Sand making machine: finely crushing and shaping stones to produce high-quality sand.

Circular vibration sieve: used for sand screening, divided into coarse sand, medium sand, fine sand and other specifications.

Sand washing machine (optional): clean sand, remove fine powder and improve sand quality.

Conveyor: Connect all equipment to ensure smooth flow of materials.

Centralized electronic control system: realize automatic control and improve production efficiency.

Technical Advantages and Application Prospects

Complete set of matching, better quality of finished products: choose the equipment of Shibang Group, such as C6X series jaw crusher, HST single cylinder hydraulic cone crusher and VSI6X series impact crusher, which can ensure efficient crushing and high-quality finished products and meet the engineering standards.

Highly automated, good comprehensive benefits: The highly automated design of the production line improves production efficiency, reduces maintenance costs and production costs, the quality of finished products is stable, and the economic benefits are significant.

Both shaping sand making and mode switching freely: VSI6X series impact crusher can not only carry out efficient sand making, but also has shaping function, simplifying equipment configuration and meeting diversified production needs.

Strong compression resistance, durability and reliability: F5X series vibrating feeder is designed to withstand large warehouse pressure and high load, adapt to harsh initial feeding conditions, and ensure stable operation of the production line.

Conclusion

Limestone sand production line can not only efficiently transform limestone resources, but also meet the strict requirements of sand and gravel materials in high-rise buildings, water conservancy power stations, concrete mixing stations and other fields. With its short-term investment recovery cyc

Previous: SMP Crusher

Next: SMP Crusher

Limestone as the 1 common ore, the main component is calcium carbonate (CaCO), Mohs hardness of 3, belongs to soft rock. It has the characteristics of chemical resistance, acid resistance, and is not easy to corrode, and is widely used in many fields s

Limestone as the 1 common ore, the main component is calcium carbonate (CaCO), Mohs hardness of 3, belongs to soft rock. It has the characteristics of chemical resistance, acid resistance, and is not easy to corrode, and is widely used in many fields such as architecture, glass, paint, and desiccant. In order to meet the growing demand for construction and infrastructure, the efficient operation of limestone sand production lines has become an important issue in the mining industry. The following is an introduction to how to convert this valuable resource into high-quality sand and gravel materials through a limestone sand production line.

Limestone sand production line price

Process flow of limestone crushing production line

Limestone sand production line mainly includes four stages: coarse crushing, medium crushing, sand making and screening.

The first stage: coarse crushing

After the limestone ore is mined from the mountain, the block material is transported to the silo by blasting operation. Through the vibrating feeder, the stone is evenly fed into the jaw crusher for preliminary coarse crushing treatment. The jaw crusher can effectively crush large pieces of stone into medium particle size, ready for subsequent processing.

The second stage: broken

The coarsely crushed stones are screened by a vibrating screen, and the screened medium granules are transported to the impact crusher through a belt conveyor for further medium crushing treatment. The crushed stones are screened by a vibrating screen again, and the stones that meet the customer's particle size requirements are sent to the finished product pile, and those that do not meet the requirements are returned to the impact crusher to continue crushing, forming a closed cycle.

The third stage: sand making

The crushed stone is transported to the sand making machine through the belt conveyor. The sand making machine further breaks and shapes the stone to produce high-quality sand. According to different needs, you can choose a double-rotor sand making machine, an impact sand making machine or a vertical shaft sand making machine to meet specific sand making requirements.

The fourth stage: screening

The finely crushed and reshaped sand is screened for coarse sand, medium sand and fine sand through a circular vibration screen. In order to meet the strict requirements of sand powder content, sand washing machine can be equipped after screening. The sand washing machine can effectively remove the fine powder in the sand, improve the purity of the sand, and recycle the sewage through the fine sand recovery device, reduce the environmental pollution and improve the sand production.

Equipment configuration of limestone sand production line

The complete limestone sand production line includes the following main equipment:

Vibrating feeder: responsible for evenly feeding the stone into the crusher cavity.

Jaw crusher: used for preliminary crushing, crushing large pieces of stone into medium particle size.

Impact crusher: used for medium crushing to further crush medium-sized stone.

Sand making machine: finely crushing and shaping stones to produce high-quality sand.

Circular vibration sieve: used for sand screening, divided into coarse sand, medium sand, fine sand and other specifications.

Sand washing machine (optional): clean sand, remove fine powder and improve sand quality.

Conveyor: Connect all equipment to ensure smooth flow of materials.

Centralized electronic control system: realize automatic control and improve production efficiency.

Technical Advantages and Application Prospects

Complete set of matching, better quality of finished products: choose the equipment of Shibang Group, such as C6X series jaw crusher, HST single cylinder hydraulic cone crusher and VSI6X series impact crusher, which can ensure efficient crushing and high-quality finished products and meet the engineering standards.

Highly automated, good comprehensive benefits: The highly automated design of the production line improves production efficiency, reduces maintenance costs and production costs, the quality of finished products is stable, and the economic benefits are significant.

Both shaping sand making and mode switching freely: VSI6X series impact crusher can not only carry out efficient sand making, but also has shaping function, simplifying equipment configuration and meeting diversified production needs.

Strong compression resistance, durability and reliability: F5X series vibrating feeder is designed to withstand large warehouse pressure and high load, adapt to harsh initial feeding conditions, and ensure stable operation of the production line.

Conclusion

Limestone sand production line can not only efficiently transform limestone resources, but also meet the strict requirements of sand and gravel materials in high-rise buildings, water conservancy power stations, concrete mixing stations and other fields. With its short-term investment recovery cyc

Previous: SMP Crusher

Next: SMP Crusher

How to configure the production line of 500 tons of stones

How to configure the production line of 500 tons of stones What are the large gravel crushers with a daily output of 10000 tons? How much is it

What are the large gravel crushers with a daily output of 10000 tons? How much is it What are the mechanism sand equipment? About how much

What are the mechanism sand equipment? About how much Model parameters of gyratory crusher

Model parameters of gyratory crusher Introduction of river pebble sand making machine and manufacturer

Introduction of river pebble sand making machine and manufacturer How to configure the production line of 500 tons of stones

How to configure the production line of 500 tons of stones What are the large gravel crushers with a daily output of 10000 tons? How much is it

What are the large gravel crushers with a daily output of 10000 tons? How much is it What are the mechanism sand equipment? About how much

What are the mechanism sand equipment? About how much Model parameters of gyratory crusher

Model parameters of gyratory crusher Introduction of river pebble sand making machine and manufacturer

Introduction of river pebble sand making machine and manufacturer