For the processing of the same material, due to different production capacity requirements or different finished product requirements, different configurations of production processes are required, but the general processing process is similar. Here we

For the processing of the same material, due to different production capacity requirements or different finished product requirements, different configurations of production processes are required, but the general processing process is similar. Here we introduce the production process of a 150-ton pebble sand making machine.

Click here to consult to understand the process of pebble sand making machine

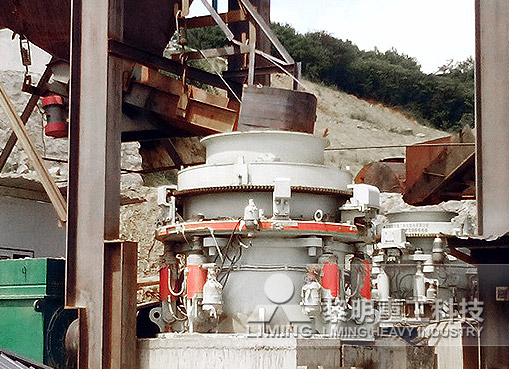

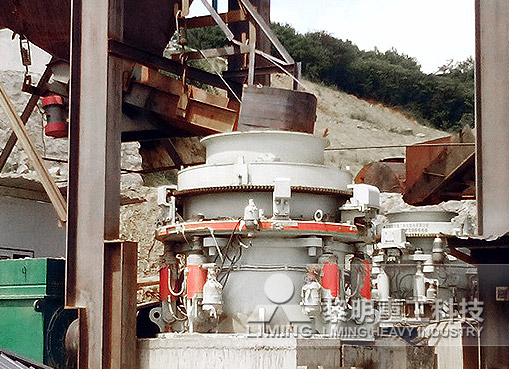

First of all, for the pebble sand making process, the equipment that needs to be selected mainly includes jaw crusher, cone crusher and sand making machine. According to the production demand of 150 tons per hour and the nature of pebbles, the models of equipment that need to be configured are mainly as follows: one PE600*900 jaw crusher, one CS160 cone crusher, two VSI1140 impact crushers, and some auxiliary production equipment, such as feeders, belt conveyors, etc.

After introducing the configuration of the 150-ton pebble sand making machine, we can now introduce its production process, which is roughly as follows: the feeder adds the pebbles to the jaw crusher for coarse crushing. The coarsely crushed pebbles are conveyed by the belt conveyor to the cone crusher for secondary crushing. If the particle size of the crushed material meets the feeding requirements of the sand making machine, then the sand making operation can be carried out. Otherwise, it is necessary to return to the crushing stage to continue the crushing link until it meets the feeding requirements of the sand making equipment. If the material processed by the sand making machine does not meet the requirements of the finished product, it is also necessary to perform the sand making operation again. This cyclic production method can ensure the uniformity of the finished product particles. The finished product particle size of this production line is between 0-5 mm.

In this sand making process, in addition to the selection of equipment, these different equipment must also match each other, so as to ensure the smooth operation of the sand making process and obtain the expected production capacity requirements. Pebbles can be used in different industries such as garden construction and sidewalks after being processed by the sand making machine. Of course, different industries have different requirements for pebbles, so sand making machine production lines with different configurations are required.

Previous: SMP Crusher

Next: SMP Crusher

For the processing of the same material, due to different production capacity requirements or different finished product requirements, different configurations of production processes are required, but the general processing process is similar. Here we

For the processing of the same material, due to different production capacity requirements or different finished product requirements, different configurations of production processes are required, but the general processing process is similar. Here we introduce the production process of a 150-ton pebble sand making machine.

Click here to consult to understand the process of pebble sand making machine

First of all, for the pebble sand making process, the equipment that needs to be selected mainly includes jaw crusher, cone crusher and sand making machine. According to the production demand of 150 tons per hour and the nature of pebbles, the models of equipment that need to be configured are mainly as follows: one PE600*900 jaw crusher, one CS160 cone crusher, two VSI1140 impact crushers, and some auxiliary production equipment, such as feeders, belt conveyors, etc.

After introducing the configuration of the 150-ton pebble sand making machine, we can now introduce its production process, which is roughly as follows: the feeder adds the pebbles to the jaw crusher for coarse crushing. The coarsely crushed pebbles are conveyed by the belt conveyor to the cone crusher for secondary crushing. If the particle size of the crushed material meets the feeding requirements of the sand making machine, then the sand making operation can be carried out. Otherwise, it is necessary to return to the crushing stage to continue the crushing link until it meets the feeding requirements of the sand making equipment. If the material processed by the sand making machine does not meet the requirements of the finished product, it is also necessary to perform the sand making operation again. This cyclic production method can ensure the uniformity of the finished product particles. The finished product particle size of this production line is between 0-5 mm.

In this sand making process, in addition to the selection of equipment, these different equipment must also match each other, so as to ensure the smooth operation of the sand making process and obtain the expected production capacity requirements. Pebbles can be used in different industries such as garden construction and sidewalks after being processed by the sand making machine. Of course, different industries have different requirements for pebbles, so sand making machine production lines with different configurations are required.

Previous: SMP Crusher

Next: SMP Crusher

Which crusher is used to crush gold ore? What are its characteristics?

Which crusher is used to crush gold ore? What are its characteristics? Why does the cone crusher shake so much?

Why does the cone crusher shake so much? What are the contents of regular inspection of jaw crusher in ore crusher?

What are the contents of regular inspection of jaw crusher in ore crusher? The process flow and equipment selection of the machine-made sand production line, the price of a machine-made sand production line

The process flow and equipment selection of the machine-made sand production line, the price of a machine-made sand production line 800 tons per hour large cone crusher: HPT multi-cylinder hydraulic cone crusher

800 tons per hour large cone crusher: HPT multi-cylinder hydraulic cone crusher Which crusher is used to crush gold ore? What are its characteristics?

Which crusher is used to crush gold ore? What are its characteristics? Why does the cone crusher shake so much?

Why does the cone crusher shake so much? What are the contents of regular inspection of jaw crusher in ore crusher?

What are the contents of regular inspection of jaw crusher in ore crusher? The process flow and equipment selection of the machine-made sand production line, the price of a machine-made sand production line

The process flow and equipment selection of the machine-made sand production line, the price of a machine-made sand production line 800 tons per hour large cone crusher: HPT multi-cylinder hydraulic cone crusher

800 tons per hour large cone crusher: HPT multi-cylinder hydraulic cone crusher