Yunnan Iron and Steel Plant built a slag crushing line to recycle iron and supply it to the brick factory to make unburned bricks. High-efficiency equipment is selected to ensure operation. Steel slag has economic and environmental value, and its utili

Yunnan Iron and Steel Plant built a slag crushing line to recycle iron and supply it to the brick factory to make unburned bricks. High-efficiency equipment is selected to ensure operation. Steel slag has economic and environmental value, and its utilization rate is high abroad. The processed steel slag has low cost and excellent performance, and has a good market prospect.

In the field of steel slag resource utilization, a steel slag crushing production line was successfully built near a steel plant in Yunnan Province, becoming an important case for promoting a green circular economy. The production line is designed to recover iron from steel slag, and at the same time, the remaining steel slag after iron removal is supplied to the local brick factory for the production of unburned bricks.

Detailed consultation on steel slag crushing production line

Project Overview

Operation time: 12 hours per day

Feed particle size: processed steel slag less than 400mm

Finished product specifications: 0-5mm

Equipment configuration

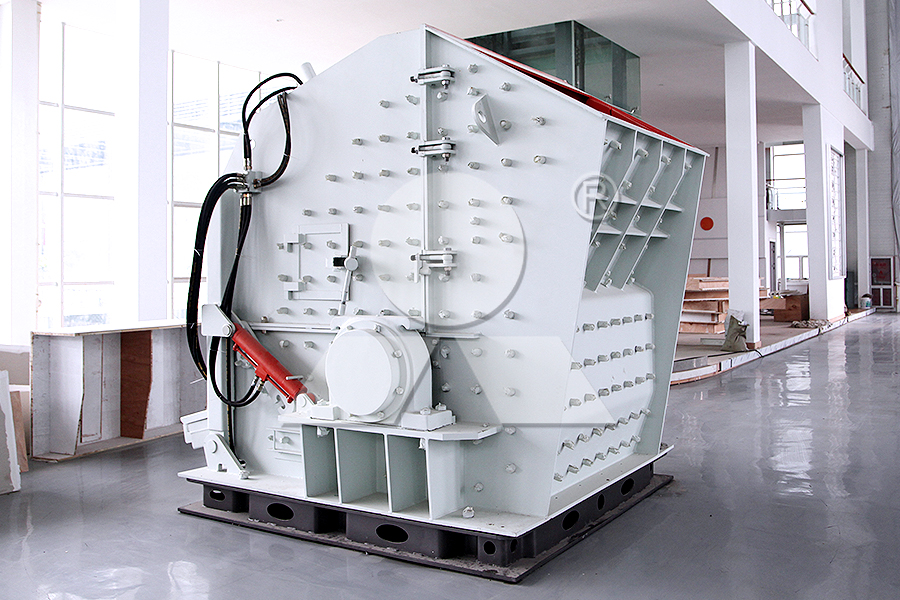

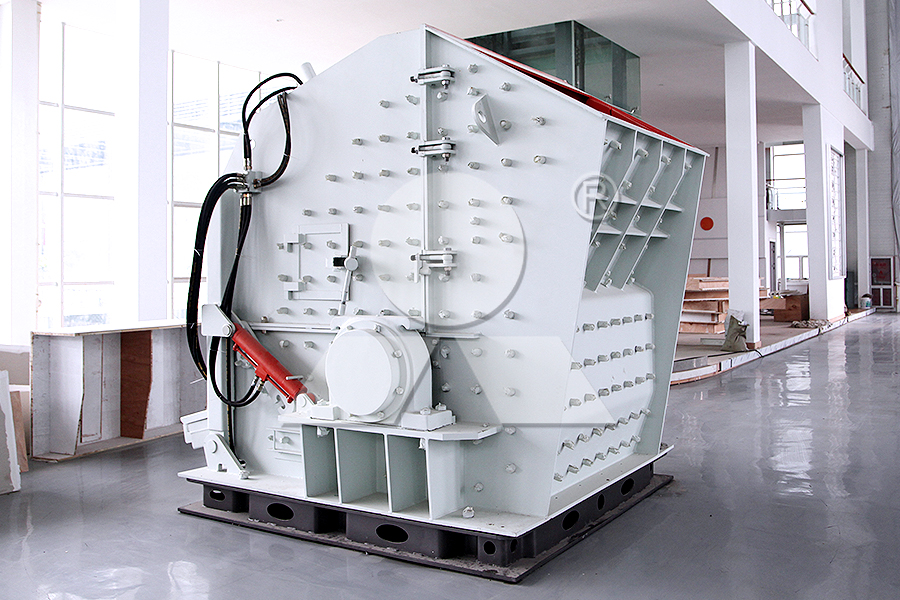

The production line uses a series of high-efficiency equipment, including PE jaw crusher, VSI5x series sand making machine, vibrating screen and feeder. These equipment ensure the stable operation and efficient output of the production line.

Current status of comprehensive utilization of steel slag

Steel slag is a by-product produced during the steel smelting process. It has significant economic and environmental value because it contains reusable components such as iron and calcium oxide. Although China produces a large amount of steel slag and its comprehensive utilization rate needs to be improved, through scientific processing technology, steel slag can be used as high-performance road aggregates, building materials, etc., which is in line with the national green development strategy.

Foreign experience and inspiration

Japan, Germany and other countries have made remarkable achievements in the utilization of steel slag, with utilization rates of more than 95% and more than 98% respectively. Steel slag is widely used in road construction, civil engineering materials and agricultural purposes in these countries.

Market prospects and advantages

The treated steel slag can replace part of natural sand and gravel, and its economic advantages are significant: the cost is more than 20% lower than that of natural stone, and it has excellent compressive properties. It is suitable for use in construction engineering, infrastructure construction and other fields.

Previous: SMP Crusher

Next: SMP Crusher

Yunnan Iron and Steel Plant built a slag crushing line to recycle iron and supply it to the brick factory to make unburned bricks. High-efficiency equipment is selected to ensure operation. Steel slag has economic and environmental value, and its utili

Yunnan Iron and Steel Plant built a slag crushing line to recycle iron and supply it to the brick factory to make unburned bricks. High-efficiency equipment is selected to ensure operation. Steel slag has economic and environmental value, and its utilization rate is high abroad. The processed steel slag has low cost and excellent performance, and has a good market prospect.

In the field of steel slag resource utilization, a steel slag crushing production line was successfully built near a steel plant in Yunnan Province, becoming an important case for promoting a green circular economy. The production line is designed to recover iron from steel slag, and at the same time, the remaining steel slag after iron removal is supplied to the local brick factory for the production of unburned bricks.

Detailed consultation on steel slag crushing production line

Project Overview

Operation time: 12 hours per day

Feed particle size: processed steel slag less than 400mm

Finished product specifications: 0-5mm

Equipment configuration

The production line uses a series of high-efficiency equipment, including PE jaw crusher, VSI5x series sand making machine, vibrating screen and feeder. These equipment ensure the stable operation and efficient output of the production line.

Current status of comprehensive utilization of steel slag

Steel slag is a by-product produced during the steel smelting process. It has significant economic and environmental value because it contains reusable components such as iron and calcium oxide. Although China produces a large amount of steel slag and its comprehensive utilization rate needs to be improved, through scientific processing technology, steel slag can be used as high-performance road aggregates, building materials, etc., which is in line with the national green development strategy.

Foreign experience and inspiration

Japan, Germany and other countries have made remarkable achievements in the utilization of steel slag, with utilization rates of more than 95% and more than 98% respectively. Steel slag is widely used in road construction, civil engineering materials and agricultural purposes in these countries.

Market prospects and advantages

The treated steel slag can replace part of natural sand and gravel, and its economic advantages are significant: the cost is more than 20% lower than that of natural stone, and it has excellent compressive properties. It is suitable for use in construction engineering, infrastructure construction and other fields.

Previous: SMP Crusher

Next: SMP Crusher

Why Jiangxi Jiaogong Group cooperated with Shibang Group to build a 3 million tons per year sand and gravel aggregate production line

Why Jiangxi Jiaogong Group cooperated with Shibang Group to build a 3 million tons per year sand and gravel aggregate production line How to choose the right crusher for limestone crushing production line

How to choose the right crusher for limestone crushing production line How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete?

How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete? Can cone crusher process iron ore? How much does one cost?

Can cone crusher process iron ore? How much does one cost? What factors should be paid attention to when choosing large stone crusher equipment

What factors should be paid attention to when choosing large stone crusher equipment Why Jiangxi Jiaogong Group cooperated with Shibang Group to build a 3 million tons per year sand and gravel aggregate production line

Why Jiangxi Jiaogong Group cooperated with Shibang Group to build a 3 million tons per year sand and gravel aggregate production line How to choose the right crusher for limestone crushing production line

How to choose the right crusher for limestone crushing production line How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete?

How to improve the quality of concrete? What equipment is needed to produce sand and gravel aggregate for concrete? Can cone crusher process iron ore? How much does one cost?

Can cone crusher process iron ore? How much does one cost? What factors should be paid attention to when choosing large stone crusher equipment

What factors should be paid attention to when choosing large stone crusher equipment