As an important support for the construction of infrastructure such as buildings, roads, and bridges, the capacity of the sand and gravel production line has always been the focus of industry attention. With the continuous advancement of technology and

As an important support for the construction of infrastructure such as buildings, roads, and bridges, the capacity of the sand and gravel production line has always been the focus of industry attention. With the continuous advancement of technology and the increasing diversification of market demand, the capacity range of sand and gravel production lines is also expanding, ranging from tens of tons to thousands of tons per hour, which can meet the needs of projects of different sizes.

Capacity configuration: flexible and tailor-made

The capacity configuration of sand and gravel production lines is not static, but is tailored according to the specific needs of customers and material characteristics. Generally speaking, the design capacity of small and medium-sized sand and gravel production lines may be between tens of tons and hundreds of tons per hour, which is suitable for small construction sites or local infrastructure construction. Large sand and gravel production lines may reach thousands of tons per hour or even higher, which can meet the needs of large-scale projects or long-term supply.

When configuring a sand and gravel production line, it is necessary to comprehensively consider factors such as the hardness, particle size, humidity of the raw materials, and the specification requirements of the finished sand and gravel. For example, for raw materials with higher hardness, more efficient crushing equipment, such as a cone crusher, may be required to ensure the stable operation and efficient output of the production line. For raw materials with higher humidity, it is necessary to consider adding sand washing equipment to improve the quality of the finished sand and gravel.

Equipment selection: high efficiency and energy saving, stable and reliable

The selection of a full set of equipment for the sand and gravel production line is directly related to the production capacity and efficiency of the production line. In terms of crushing equipment, jaw crushers, cone crushers, impact crushers, etc. have their own advantages and disadvantages, and need to be selected according to the characteristics of the raw materials and production needs. Screening equipment usually uses a vibrating screen, and its screening efficiency and accuracy are crucial to the overall efficiency of the production line.

In addition, conveying equipment, feeding equipment, and central electronic control systems are also indispensable parts of the sand and gravel production line. Efficient conveying equipment can ensure the smooth transmission of materials on the production line, reducing waiting time and energy consumption. The advanced central electronic control system can realize the automatic management and remote control of the production line, and improve production efficiency and safety.

Capacity improvement: technological innovation, management optimization

In order to improve the capacity of the sand and gravel production line, technological innovation and management optimization are equally important. On the one hand, by introducing advanced crushing, screening and sand washing equipment, the processing capacity and efficiency of the production line can be significantly improved. For example, the use of a vertical shaft impact sand making machine can produce machine-made sand with rounded particles and reasonable grading, which meets the requirements of high-standard building materials.

On the other hand, strengthening the daily management and maintenance of the production line is also the key to improving production capacity. Regularly inspect and maintain the equipment to ensure the normal operation of the equipment and extend its service life. At the same time, optimizing the production process and operating specifications, reducing unnecessary waste and downtime, is also an effective way to improve production capacity.

Actual case: the perfect combination of production capacity and efficiency

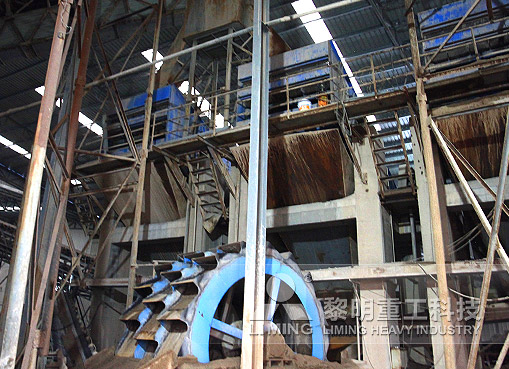

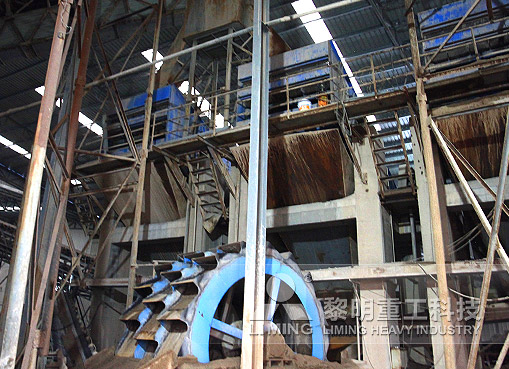

Taking a large sand and gravel production line as an example, the production line uses a full set of advanced feeders, jaw crushers, cone crushers, vibrating screens and conveyor belts, with a designed production capacity of 1,000 tons per hour. In actual operation, the production line has achieved efficient and stable operation by optimizing the production process and strengthening equipment maintenance. The sand and gravel aggregates it produces have good particle shape and reasonable grading, and are widely used in local infrastructure construction projects, winning unanimous praise from customers.

The production capacity of a full set of equipment for a sand and gravel production line is a complex and changeable issue, which needs to be tailored according to the specific needs and material characteristics of customers. Through reasonable equipment selection, technological innovation and management optimization, the production capacity and efficiency of the production line can be significantly improved to meet the needs of projects of different sizes. In future development, with the continuous advancement of technology and the continuous changes in market demand, the capacity configuration of sand and gravel production lines will become more flexible, diverse, efficient and energy-saving.

Previous: SMP Crusher

Next: SMP Crusher

As an important support for the construction of infrastructure such as buildings, roads, and bridges, the capacity of the sand and gravel production line has always been the focus of industry attention. With the continuous advancement of technology and

As an important support for the construction of infrastructure such as buildings, roads, and bridges, the capacity of the sand and gravel production line has always been the focus of industry attention. With the continuous advancement of technology and the increasing diversification of market demand, the capacity range of sand and gravel production lines is also expanding, ranging from tens of tons to thousands of tons per hour, which can meet the needs of projects of different sizes.

Capacity configuration: flexible and tailor-made

The capacity configuration of sand and gravel production lines is not static, but is tailored according to the specific needs of customers and material characteristics. Generally speaking, the design capacity of small and medium-sized sand and gravel production lines may be between tens of tons and hundreds of tons per hour, which is suitable for small construction sites or local infrastructure construction. Large sand and gravel production lines may reach thousands of tons per hour or even higher, which can meet the needs of large-scale projects or long-term supply.

When configuring a sand and gravel production line, it is necessary to comprehensively consider factors such as the hardness, particle size, humidity of the raw materials, and the specification requirements of the finished sand and gravel. For example, for raw materials with higher hardness, more efficient crushing equipment, such as a cone crusher, may be required to ensure the stable operation and efficient output of the production line. For raw materials with higher humidity, it is necessary to consider adding sand washing equipment to improve the quality of the finished sand and gravel.

Equipment selection: high efficiency and energy saving, stable and reliable

The selection of a full set of equipment for the sand and gravel production line is directly related to the production capacity and efficiency of the production line. In terms of crushing equipment, jaw crushers, cone crushers, impact crushers, etc. have their own advantages and disadvantages, and need to be selected according to the characteristics of the raw materials and production needs. Screening equipment usually uses a vibrating screen, and its screening efficiency and accuracy are crucial to the overall efficiency of the production line.

In addition, conveying equipment, feeding equipment, and central electronic control systems are also indispensable parts of the sand and gravel production line. Efficient conveying equipment can ensure the smooth transmission of materials on the production line, reducing waiting time and energy consumption. The advanced central electronic control system can realize the automatic management and remote control of the production line, and improve production efficiency and safety.

Capacity improvement: technological innovation, management optimization

In order to improve the capacity of the sand and gravel production line, technological innovation and management optimization are equally important. On the one hand, by introducing advanced crushing, screening and sand washing equipment, the processing capacity and efficiency of the production line can be significantly improved. For example, the use of a vertical shaft impact sand making machine can produce machine-made sand with rounded particles and reasonable grading, which meets the requirements of high-standard building materials.

On the other hand, strengthening the daily management and maintenance of the production line is also the key to improving production capacity. Regularly inspect and maintain the equipment to ensure the normal operation of the equipment and extend its service life. At the same time, optimizing the production process and operating specifications, reducing unnecessary waste and downtime, is also an effective way to improve production capacity.

Actual case: the perfect combination of production capacity and efficiency

Taking a large sand and gravel production line as an example, the production line uses a full set of advanced feeders, jaw crushers, cone crushers, vibrating screens and conveyor belts, with a designed production capacity of 1,000 tons per hour. In actual operation, the production line has achieved efficient and stable operation by optimizing the production process and strengthening equipment maintenance. The sand and gravel aggregates it produces have good particle shape and reasonable grading, and are widely used in local infrastructure construction projects, winning unanimous praise from customers.

The production capacity of a full set of equipment for a sand and gravel production line is a complex and changeable issue, which needs to be tailored according to the specific needs and material characteristics of customers. Through reasonable equipment selection, technological innovation and management optimization, the production capacity and efficiency of the production line can be significantly improved to meet the needs of projects of different sizes. In future development, with the continuous advancement of technology and the continuous changes in market demand, the capacity configuration of sand and gravel production lines will become more flexible, diverse, efficient and energy-saving.

Previous: SMP Crusher

Next: SMP Crusher

Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development The impact of the ratio of basalt to river sand on the project

The impact of the ratio of basalt to river sand on the project 500 tons per hour granite crushing production line equipment unveiled

500 tons per hour granite crushing production line equipment unveiled Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development The impact of the ratio of basalt to river sand on the project

The impact of the ratio of basalt to river sand on the project 500 tons per hour granite crushing production line equipment unveiled

500 tons per hour granite crushing production line equipment unveiled