In the process of rough crushing of cobblestones, the equipment that needs to be used is a jaw crusher. This machine has various models and complete functions, and can meet different rough crushing needs. However, for specific crushing needs, you must

In the process of rough crushing of cobblestones, the equipment that needs to be used is a jaw crusher. This machine has various models and complete functions, and can meet different rough crushing needs. However, for specific crushing needs, you must choose the appropriate model. Jaw crusher, otherwise it will cause great damage to production, so how to choose this machine?

Click for consultation on the price of cobblestone crushing equipment

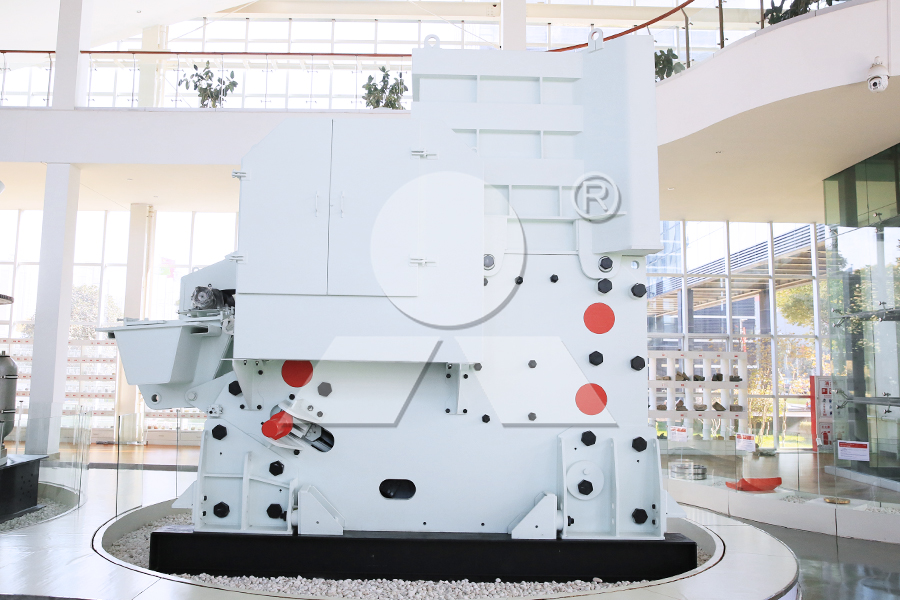

1. Production advantages of cobblestone jaw crusher

In the cobblestone rough crushing operation, the jaw crusher relies on its unique three-dimensional structure design to achieve the advantages of small footprint and low infrastructure cost. Its high crushing ratio effectively increases production and ensures significant crushing effects. . In addition, this machine can simplify the production process and significantly reduce operating costs. In actual operation, the jaw crusher has a low failure rate and operates smoothly, reducing production time lost due to shutdown maintenance. The finished cobblestones processed by this machine have complete particle shape and high quality, fully meeting production needs. To sum up, the jaw crusher is an ideal choice for coarse crushing of cobblestones.

2. Selection of cobblestone jaw crusher

When selecting the jaw crusher model required for cobblestone crushing, it is mainly based on production needs. Different models of jaw crushers have differences in material processing size, production capacity, energy consumption and finished product particles. Therefore, the appropriate model needs to be selected according to specific production needs. , when choosing, quality, after-sales service and price are also important considerations. Quality is related to the performance and life of the equipment, after-sales service affects the ease of use, and price is directly related to the investment cost. These factors all have an important impact on the use effect and investment return of the jaw crusher. Therefore, comprehensive considerations must be taken when selecting the type and cannot be ignored. .

In addition, when selecting a cobblestone jaw crusher, one thing to pay attention to is the choice of manufacturer. Due to market competition and other factors, different manufacturers may invest in the technology or manufacturing process of the machine. The process selection is different, which will affect the use of the machine, so the choice of manufacturer is also very important.

Previous: SMP Crusher

Next: SMP Crusher

In the process of rough crushing of cobblestones, the equipment that needs to be used is a jaw crusher. This machine has various models and complete functions, and can meet different rough crushing needs. However, for specific crushing needs, you must

In the process of rough crushing of cobblestones, the equipment that needs to be used is a jaw crusher. This machine has various models and complete functions, and can meet different rough crushing needs. However, for specific crushing needs, you must choose the appropriate model. Jaw crusher, otherwise it will cause great damage to production, so how to choose this machine?

Click for consultation on the price of cobblestone crushing equipment

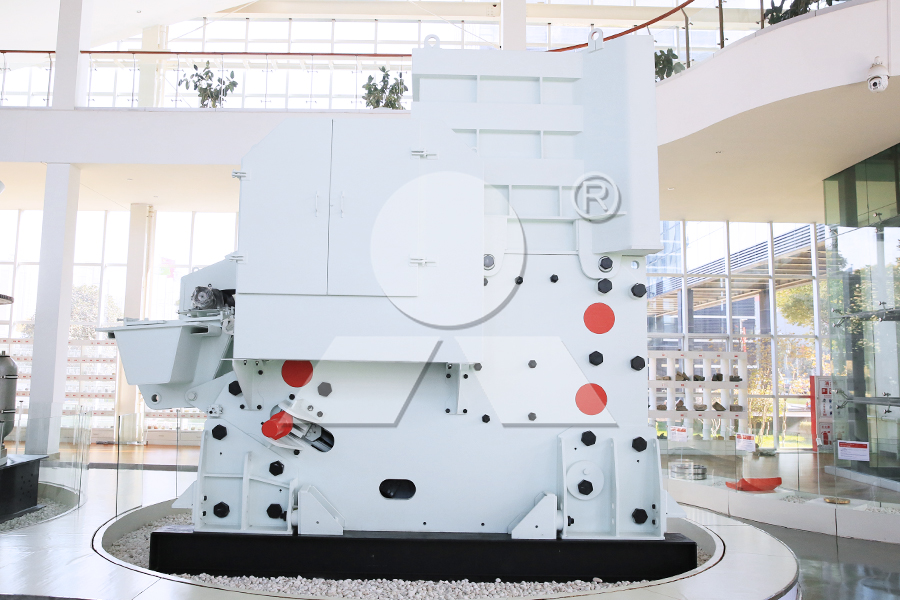

1. Production advantages of cobblestone jaw crusher

In the cobblestone rough crushing operation, the jaw crusher relies on its unique three-dimensional structure design to achieve the advantages of small footprint and low infrastructure cost. Its high crushing ratio effectively increases production and ensures significant crushing effects. . In addition, this machine can simplify the production process and significantly reduce operating costs. In actual operation, the jaw crusher has a low failure rate and operates smoothly, reducing production time lost due to shutdown maintenance. The finished cobblestones processed by this machine have complete particle shape and high quality, fully meeting production needs. To sum up, the jaw crusher is an ideal choice for coarse crushing of cobblestones.

2. Selection of cobblestone jaw crusher

When selecting the jaw crusher model required for cobblestone crushing, it is mainly based on production needs. Different models of jaw crushers have differences in material processing size, production capacity, energy consumption and finished product particles. Therefore, the appropriate model needs to be selected according to specific production needs. , when choosing, quality, after-sales service and price are also important considerations. Quality is related to the performance and life of the equipment, after-sales service affects the ease of use, and price is directly related to the investment cost. These factors all have an important impact on the use effect and investment return of the jaw crusher. Therefore, comprehensive considerations must be taken when selecting the type and cannot be ignored. .

In addition, when selecting a cobblestone jaw crusher, one thing to pay attention to is the choice of manufacturer. Due to market competition and other factors, different manufacturers may invest in the technology or manufacturing process of the machine. The process selection is different, which will affect the use of the machine, so the choice of manufacturer is also very important.

Previous: SMP Crusher

Next: SMP Crusher

300 tons per hour sand and gravel production line configuration plan

300 tons per hour sand and gravel production line configuration plan How to choose brick slag crushing equipment

How to choose brick slag crushing equipment 600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production Calcite crushing equipment, what equipment is needed for calcite ore crushing

Calcite crushing equipment, what equipment is needed for calcite ore crushing 300 tons per hour sand and gravel production line configuration plan

300 tons per hour sand and gravel production line configuration plan How to choose brick slag crushing equipment

How to choose brick slag crushing equipment 600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production Calcite crushing equipment, what equipment is needed for calcite ore crushing

Calcite crushing equipment, what equipment is needed for calcite ore crushing