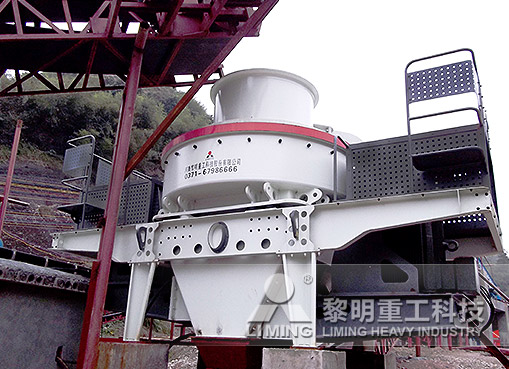

The hazards and causes of motor vibration in the crusher during the operation of the gravel production line are mainly as follows:Click here to learn about crushing equipment

The hazards and causes of motor vibration in the crusher during the operation of the gravel production line are mainly as follows:

Click here to learn about crushing equipment

First, the hazards of motor vibration

1) Vibration will consume a certain amount of energy, which will reduce the efficiency of the motor, and directly affect the crushing process of the crusher;

2) Vibration will cause more wear on the bearings inside the motor, and its service life will be greatly reduced, which will increase the operating cost of the crusher;

3) Vibration will cause the motor rotor to bend or break, and reduce the tightness of some parts, which will directly affect the operation of equipment such as the crusher;

4) The vibration of the motor will reduce the insulation resistance, which will cause great hidden dangers to the safety of the crusher staff;

Second, the cause of motor vibration

Motor vibration is mainly caused by base vibration, rotor imbalance and motor bearing vibration. Base vibration originates from the rotor excitation force or the electromagnetic vibration of the stator core, and needs to be solved from these two aspects. Rotor imbalance is caused by static, dynamic or mixed imbalance of the crusher rotor. Adjusting the rotor balance is an effective means to reduce vibration. As for motor bearing vibration, it is usually caused by the relative vibration between the bearing and the rotor or the vibration of the bearing seat. The solution lies in taking measures for these two aspects. Therefore, taking corresponding solutions for different causes of motor vibration is the key to ensuring the stable operation of the motor.

Previous: SMP Crusher

Next: SMP Crusher

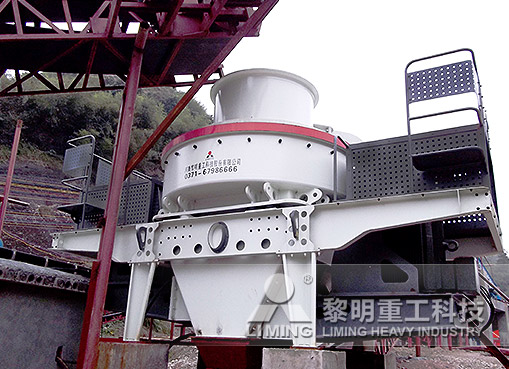

The hazards and causes of motor vibration in the crusher during the operation of the gravel production line are mainly as follows:Click here to learn about crushing equipment

The hazards and causes of motor vibration in the crusher during the operation of the gravel production line are mainly as follows:

Click here to learn about crushing equipment

First, the hazards of motor vibration

1) Vibration will consume a certain amount of energy, which will reduce the efficiency of the motor, and directly affect the crushing process of the crusher;

2) Vibration will cause more wear on the bearings inside the motor, and its service life will be greatly reduced, which will increase the operating cost of the crusher;

3) Vibration will cause the motor rotor to bend or break, and reduce the tightness of some parts, which will directly affect the operation of equipment such as the crusher;

4) The vibration of the motor will reduce the insulation resistance, which will cause great hidden dangers to the safety of the crusher staff;

Second, the cause of motor vibration

Motor vibration is mainly caused by base vibration, rotor imbalance and motor bearing vibration. Base vibration originates from the rotor excitation force or the electromagnetic vibration of the stator core, and needs to be solved from these two aspects. Rotor imbalance is caused by static, dynamic or mixed imbalance of the crusher rotor. Adjusting the rotor balance is an effective means to reduce vibration. As for motor bearing vibration, it is usually caused by the relative vibration between the bearing and the rotor or the vibration of the bearing seat. The solution lies in taking measures for these two aspects. Therefore, taking corresponding solutions for different causes of motor vibration is the key to ensuring the stable operation of the motor.

Previous: SMP Crusher

Next: SMP Crusher