The sand making machine production line generally includes two parts: crushing and sand making. Different materials, output, particle size requirements, etc., require different equipment. Here is a detailed introduction.1. Jaw crushe

The sand making machine production line generally includes two parts: crushing and sand making. Different materials, output, particle size requirements, etc., require different equipment. Here is a detailed introduction.

1. Jaw crusher (coarse crushing, head crushing): When faced with processing large-grained raw materials, equipment using extrusion crushing technology is preferred. This equipment is famous for its deep cavity crushing design, which effectively improves operating efficiency. Its unique adjustable discharge granularity function ensures diverse product specifications. The equipment has strong processing capabilities and a production capacity ranging from 12 to 1510 tons/hour, making it easy to handle mass production tasks. At the same time, the upper limit of the feed particle size can reach 1280mm, which is widely adaptable to a variety of raw material specifications, providing efficient and flexible crushing solutions for industrial production.

2. Impact crusher (medium crushing, medium crushing): This equipment is specially designed for brittle and soft stones. It uses the principle of efficient impact crushing to ensure that materials are evenly and finely crushed. The processed finished stone is cube-shaped with excellent particle shape, meeting high standard requirements. Production capacity: 50-2000 tons/hour, feed particle size ≤1300mm;

3. Cone crusher (medium crushing, medium crushing): This equipment uses the squeeze crushing principle, combined with multiple cavity designs, and is specially customized for hard stone materials and large processing plants. Its high-efficiency crushing capacity, combined with durable wearing parts, significantly extends the service life and reduces maintenance costs. It is an ideal choice in the field of hard stone processing, ensuring an efficient and stable production process. Production capacity: 45-2130 tons/hour , Feeding particle size ≤ 350mm;

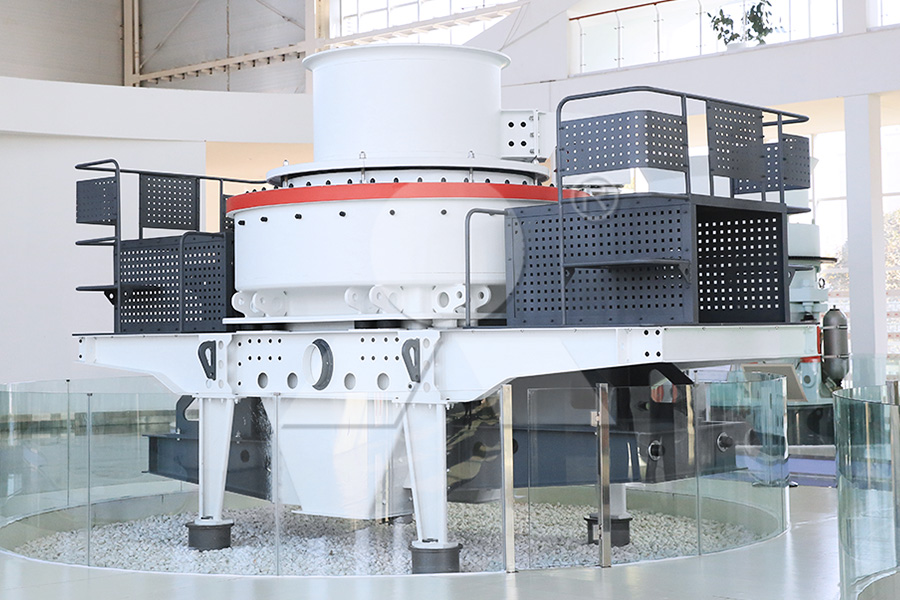

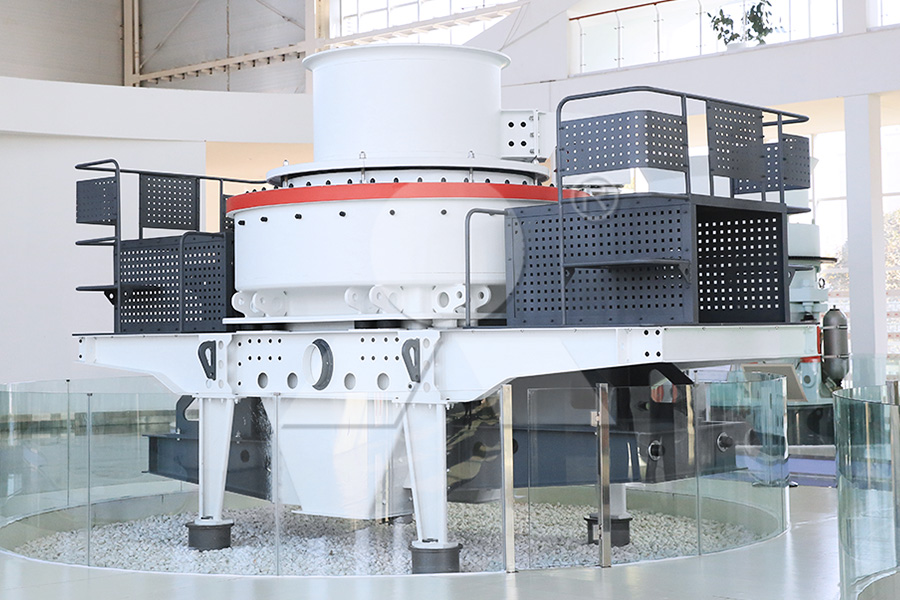

4. Sand making machine: In order to meet the crushing needs of different users, the structure of the crushing cavity is optimized, and the "rock on stone" and "rock on iron" crushing modes are configured, and the "rock on stone" material lining and "stone on iron" impact block structure All are specially designed according to the working status of the equipment, which significantly improves the crushing efficiency of the equipment. Production capacity: 60-640 tons/hour, feed particle size ≤50mm;

5. Auxiliary equipment: including screening equipment, feeders, sand washers, conveyors, etc., mainly connecting various crushing and sand making equipment to ensure stable operation of the entire production line.

How much does a set of equipment for a sand making machine production line cost?

A complete set of sand making machine equipment configuration: feeder + jaw crusher + impact crusher/cone crusher + sand making machine + vibrating screen + sand washing machine + conveyor.

How to configure a complete sand making machine production line needs to consider the specific needs of the customer. Output and particle size requirements all have an impact on the selection of equipment. According to the market price, a production line generally ranges from 300,000 to over one million.

Previous: SMP Crusher

Next: SMP Crusher

The sand making machine production line generally includes two parts: crushing and sand making. Different materials, output, particle size requirements, etc., require different equipment. Here is a detailed introduction.1. Jaw crushe

The sand making machine production line generally includes two parts: crushing and sand making. Different materials, output, particle size requirements, etc., require different equipment. Here is a detailed introduction.

1. Jaw crusher (coarse crushing, head crushing): When faced with processing large-grained raw materials, equipment using extrusion crushing technology is preferred. This equipment is famous for its deep cavity crushing design, which effectively improves operating efficiency. Its unique adjustable discharge granularity function ensures diverse product specifications. The equipment has strong processing capabilities and a production capacity ranging from 12 to 1510 tons/hour, making it easy to handle mass production tasks. At the same time, the upper limit of the feed particle size can reach 1280mm, which is widely adaptable to a variety of raw material specifications, providing efficient and flexible crushing solutions for industrial production.

2. Impact crusher (medium crushing, medium crushing): This equipment is specially designed for brittle and soft stones. It uses the principle of efficient impact crushing to ensure that materials are evenly and finely crushed. The processed finished stone is cube-shaped with excellent particle shape, meeting high standard requirements. Production capacity: 50-2000 tons/hour, feed particle size ≤1300mm;

3. Cone crusher (medium crushing, medium crushing): This equipment uses the squeeze crushing principle, combined with multiple cavity designs, and is specially customized for hard stone materials and large processing plants. Its high-efficiency crushing capacity, combined with durable wearing parts, significantly extends the service life and reduces maintenance costs. It is an ideal choice in the field of hard stone processing, ensuring an efficient and stable production process. Production capacity: 45-2130 tons/hour , Feeding particle size ≤ 350mm;

4. Sand making machine: In order to meet the crushing needs of different users, the structure of the crushing cavity is optimized, and the "rock on stone" and "rock on iron" crushing modes are configured, and the "rock on stone" material lining and "stone on iron" impact block structure All are specially designed according to the working status of the equipment, which significantly improves the crushing efficiency of the equipment. Production capacity: 60-640 tons/hour, feed particle size ≤50mm;

5. Auxiliary equipment: including screening equipment, feeders, sand washers, conveyors, etc., mainly connecting various crushing and sand making equipment to ensure stable operation of the entire production line.

How much does a set of equipment for a sand making machine production line cost?

A complete set of sand making machine equipment configuration: feeder + jaw crusher + impact crusher/cone crusher + sand making machine + vibrating screen + sand washing machine + conveyor.

How to configure a complete sand making machine production line needs to consider the specific needs of the customer. Output and particle size requirements all have an impact on the selection of equipment. According to the market price, a production line generally ranges from 300,000 to over one million.

Previous: SMP Crusher

Next: SMP Crusher

Equipment selection and process of manganese ore crushing production line

Equipment selection and process of manganese ore crushing production line Dolomite crushing and sand making production line

Dolomite crushing and sand making production line Design scheme and equipment configuration of 100 tons per hour steel slag sand making production line

Design scheme and equipment configuration of 100 tons per hour steel slag sand making production line What are the machines for crushing stones into sand and how much do they cost?

What are the machines for crushing stones into sand and how much do they cost? What are the models of 100 tons per hour stone cone crusher? How much does one cost?

What are the models of 100 tons per hour stone cone crusher? How much does one cost? Equipment selection and process of manganese ore crushing production line

Equipment selection and process of manganese ore crushing production line Dolomite crushing and sand making production line

Dolomite crushing and sand making production line Design scheme and equipment configuration of 100 tons per hour steel slag sand making production line

Design scheme and equipment configuration of 100 tons per hour steel slag sand making production line What are the machines for crushing stones into sand and how much do they cost?

What are the machines for crushing stones into sand and how much do they cost? What are the models of 100 tons per hour stone cone crusher? How much does one cost?

What are the models of 100 tons per hour stone cone crusher? How much does one cost?