The efficiency of a complete set of equipment for a sand and gravel production line is not a fixed value, but is affected by many factors. The following is a specific analysis:1. Equipment selection and configurationCrushing e

The efficiency of a complete set of equipment for a sand and gravel production line is not a fixed value, but is affected by many factors. The following is a specific analysis:

1. Equipment selection and configuration

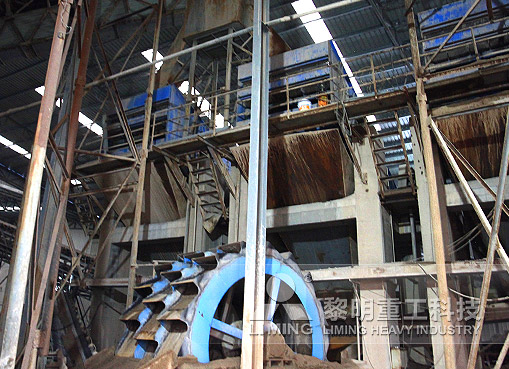

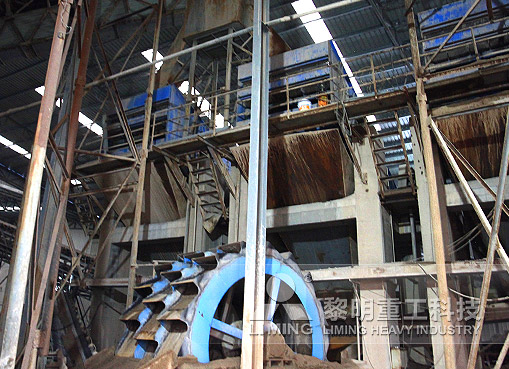

Crushing equipment: The selection and configuration of equipment such as jaw crushers, cone crushers, and impact crushers directly affect the efficiency of the production line. Different types of equipment have different processing capabilities and crushing efficiencies. Therefore, when selecting equipment, it is necessary to make reasonable combinations based on the hardness, particle size, and production requirements of the raw materials.

Screening equipment: The screening efficiency and processing capacity of screening equipment such as circular vibrating screens are also key factors affecting the efficiency of the production line. Efficient screening equipment can ensure that materials are separated quickly and accurately, improving the overall efficiency of the production line.

Sand making equipment: The sand making efficiency and finished product particle shape quality of sand making equipment such as vertical shaft impact sand making machines also have an important impact on the efficiency of the production line.

2. Raw material characteristics

Raw material hardness: Raw materials with greater hardness require longer crushing time and greater crushing force, which affects the efficiency of the production line.

Raw material particle size: The size of the raw material particle size also affects the processing capacity and efficiency of the crushing equipment. Raw materials with larger particle sizes require longer crushing time, while raw materials with smaller particle sizes may be easier to crush.

3. Production line layout and process flow

Production line layout: Reasonable production line layout can ensure the smooth transmission of materials between equipment, reduce unnecessary waiting time and energy consumption, and improve the efficiency of the production line.

Process flow: Optimized process flow can reduce repeated crushing and screening of materials and improve the overall efficiency of the production line. For example, the use of closed-loop crushing and screening technology can ensure that unqualified materials are returned to the crusher for re-crushing in time, increasing the output of qualified products.

4. Equipment maintenance and management

Equipment maintenance: Regular equipment maintenance can ensure the normal operation of equipment and extend its service life, reduce downtime caused by equipment failure, and improve the efficiency of the production line.

Equipment management: Scientific equipment management can optimize the operating parameters and operating procedures of equipment, improve equipment utilization and production efficiency.

Previous: SMP Crusher

Next: SMP Crusher

The efficiency of a complete set of equipment for a sand and gravel production line is not a fixed value, but is affected by many factors. The following is a specific analysis:1. Equipment selection and configurationCrushing e

The efficiency of a complete set of equipment for a sand and gravel production line is not a fixed value, but is affected by many factors. The following is a specific analysis:

1. Equipment selection and configuration

Crushing equipment: The selection and configuration of equipment such as jaw crushers, cone crushers, and impact crushers directly affect the efficiency of the production line. Different types of equipment have different processing capabilities and crushing efficiencies. Therefore, when selecting equipment, it is necessary to make reasonable combinations based on the hardness, particle size, and production requirements of the raw materials.

Screening equipment: The screening efficiency and processing capacity of screening equipment such as circular vibrating screens are also key factors affecting the efficiency of the production line. Efficient screening equipment can ensure that materials are separated quickly and accurately, improving the overall efficiency of the production line.

Sand making equipment: The sand making efficiency and finished product particle shape quality of sand making equipment such as vertical shaft impact sand making machines also have an important impact on the efficiency of the production line.

2. Raw material characteristics

Raw material hardness: Raw materials with greater hardness require longer crushing time and greater crushing force, which affects the efficiency of the production line.

Raw material particle size: The size of the raw material particle size also affects the processing capacity and efficiency of the crushing equipment. Raw materials with larger particle sizes require longer crushing time, while raw materials with smaller particle sizes may be easier to crush.

3. Production line layout and process flow

Production line layout: Reasonable production line layout can ensure the smooth transmission of materials between equipment, reduce unnecessary waiting time and energy consumption, and improve the efficiency of the production line.

Process flow: Optimized process flow can reduce repeated crushing and screening of materials and improve the overall efficiency of the production line. For example, the use of closed-loop crushing and screening technology can ensure that unqualified materials are returned to the crusher for re-crushing in time, increasing the output of qualified products.

4. Equipment maintenance and management

Equipment maintenance: Regular equipment maintenance can ensure the normal operation of equipment and extend its service life, reduce downtime caused by equipment failure, and improve the efficiency of the production line.

Equipment management: Scientific equipment management can optimize the operating parameters and operating procedures of equipment, improve equipment utilization and production efficiency.

Previous: SMP Crusher

Next: SMP Crusher

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development The impact of the ratio of basalt to river sand on the project

The impact of the ratio of basalt to river sand on the project The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development The impact of the ratio of basalt to river sand on the project

The impact of the ratio of basalt to river sand on the project