With the increasing demand for sand and gravel, machine-made sand has become the mainstream. The price of sand making machine is affected by specifications, quality, output and supply and demand, and is usually between 500,000 and 3 million. Choose the

With the increasing demand for sand and gravel, machine-made sand has become the mainstream. The price of sand making machine is affected by specifications, quality, output and supply and demand, and is usually between 500,000 and 3 million. Choose the right model and configuration to improve production efficiency and achieve a considerable return on investment

With the vigorous development of infrastructure construction, the demand for sand and gravel aggregates continues to increase, and the traditional natural sand supply has been unable to meet market demand. As a result, machine-made sand has gradually become the mainstream of the market as a substitute for natural sand, promoting the rapid development and widespread application of sand making machine equipment. So, what is the cost of investing in a sand production line? Let's find out.

Quotation for a set of machine-made sand equipment

1. Factors affecting the price of sand making machine

The price of sand making machine is affected by many factors, and the specific price varies depending on the manufacturer, equipment configuration, production requirements, etc. The main influencing factors include:

Equipment specifications and models: Sand making machines have a variety of models, and different specifications and models are suitable for different production needs. Larger equipment is usually suitable for large-scale production, and the price is naturally higher; while small and medium-sized equipment is more suitable for small-scale sand and gravel plants, and the price is relatively cheap.

Quality and performance: The quality of equipment directly affects its production efficiency and service life. High-quality equipment is more expensive, but it has stable operation and low failure rate, which can bring higher return on investment. Conversely, poor-quality equipment is cheap, but may increase the cost of later repairs and replacements.

Production demand and output: The higher the output demand of the production line, the more equipment is required, and the cost will naturally increase. Therefore, the greater the output demand, the higher the overall price of the production line.

Supply and demand relationship: Changes in market supply and demand will also affect prices. When demand is high and supply is insufficient, equipment prices may rise; conversely, they may fall.

2. Types and prices of sand making equipment

Different types of sand making equipment have large price differences. The following are several common sand making machines and their price ranges:

VSI sand making machine: It is a traditional sand making equipment suitable for medium-sized production lines, and the price is about 200,000-800,000.

VSI5X sand making machine: It adopts German technology, has high crushing efficiency and longer service life, and the price is generally between 300,000 and 1.2 million.

VSI6X sand making machine: a new generation of high-efficiency and low-cost sand making and shaping equipment, with a price range of approximately RMB 200,000 to RMB 1.5 million.

3. Complete configuration of sand making production line

Sand making production line is not just a single sand making machine, it usually includes a combination of multiple equipment, and the specific configuration depends on the output demand. Common sand making production line configurations include:

Vibrating feeder: feeds the material evenly into the crusher.

Crushing equipment: such as jaw crusher, cone crusher, impact crusher, etc., for coarse and medium crushing.

Sand making machine: used to process the crushed material into machine-made sand that meets market demand.

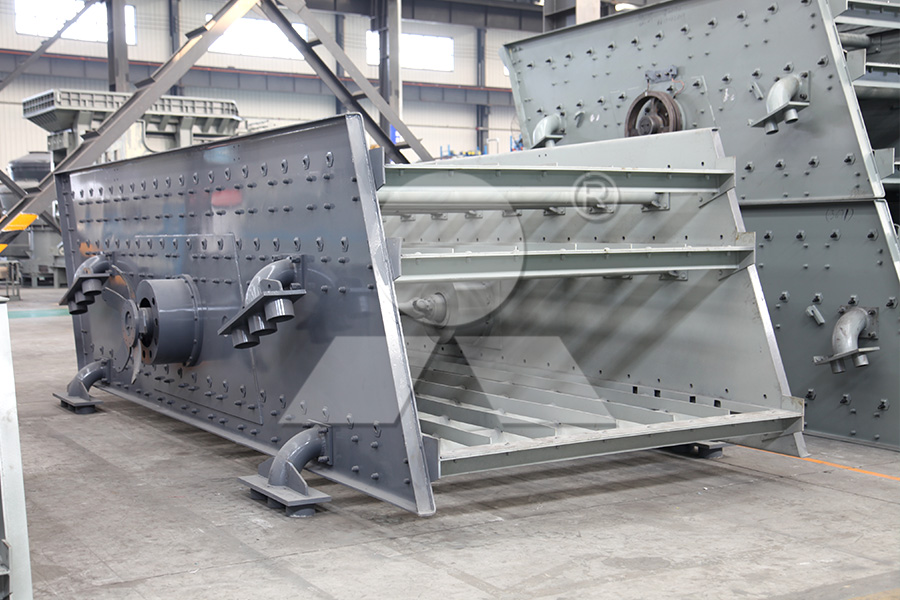

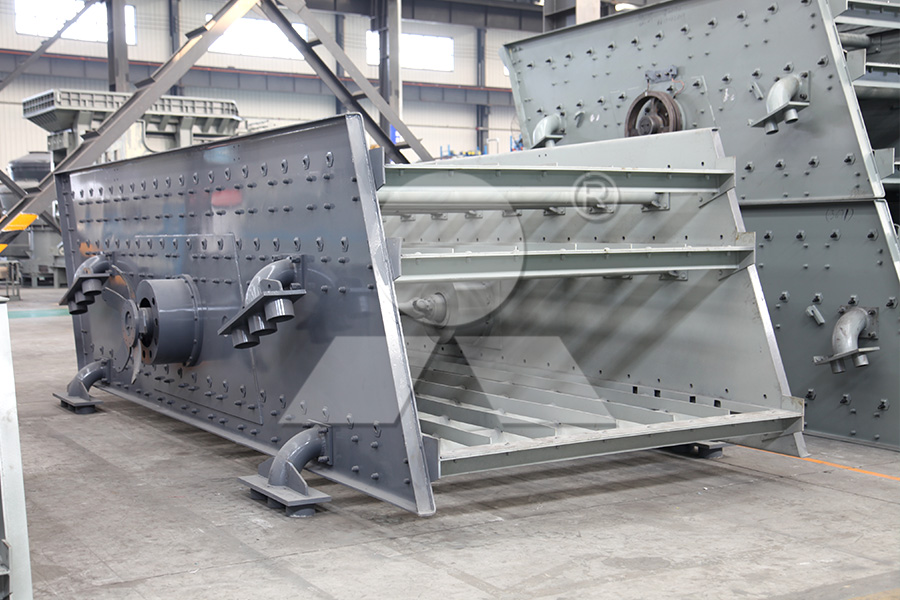

Vibrating screen: screens the material after sand making to ensure the particle size of the finished product.

Sand washing machine: used to clean machine-made sand, remove impurities, and improve the quality of the finished product.

Conveying equipment: such as belt conveyor, used to transport materials between different equipment.

The equipment selection and configuration of the entire production line will directly affect the overall investment cost. Generally speaking, the price of a small sand production line is between 500,000 and 1 million, while the price of a large-scale production line may be as high as 3 million or more.

4. How to choose a suitable sand making machine?

Choose the model according to production needs: The scale, output and type of sand and gravel required of the production line determine the choice of sand making machine. Small plants can choose HX series equipment, while large-scale sand plants are more suitable for VSI or VSI5X series.

Pay attention to cost performance and after-sales service: When purchasing sand making equipment, you should not only consider the price of the equipment, but also pay attention to the cost performance of the equipment and the after-sales service provided by the manufacturer. High-quality after-sales service can reduce the cost of later maintenance and ensure the long-term stable operation of the production line.

Consult professional manufacturers: Choose well-known and reputable manufacturers who can customize the production line according to the actual needs of customers to ensure that the equipment is highly matched with production needs.

5. Return on investment of sand production line

Although the initial investment of sand production line is large, its return on investment period is usually short. Efficient and stable production lines can greatly improve production efficiency and reduce production costs. Therefore, under the premise of reasonable configuration, in the long run, the return on investment of machine-made sand production line is very considerable.

In summary, the price of sand making machine is affected by multiple factors, usually between 500,000 and 3 million. According to different market demands, choosing the right equipment and configuration can effectively improve production efficiency and achieve a good return on investment. If you plan to invest in a sand making production line, it is recommended to consult professional manufacturers and obtain accurate quotes based on your own needs, production scale and budget.

Previous: SMP Crusher

Next: SMP Crusher

With the increasing demand for sand and gravel, machine-made sand has become the mainstream. The price of sand making machine is affected by specifications, quality, output and supply and demand, and is usually between 500,000 and 3 million. Choose the

With the increasing demand for sand and gravel, machine-made sand has become the mainstream. The price of sand making machine is affected by specifications, quality, output and supply and demand, and is usually between 500,000 and 3 million. Choose the right model and configuration to improve production efficiency and achieve a considerable return on investment

With the vigorous development of infrastructure construction, the demand for sand and gravel aggregates continues to increase, and the traditional natural sand supply has been unable to meet market demand. As a result, machine-made sand has gradually become the mainstream of the market as a substitute for natural sand, promoting the rapid development and widespread application of sand making machine equipment. So, what is the cost of investing in a sand production line? Let's find out.

Quotation for a set of machine-made sand equipment

1. Factors affecting the price of sand making machine

The price of sand making machine is affected by many factors, and the specific price varies depending on the manufacturer, equipment configuration, production requirements, etc. The main influencing factors include:

Equipment specifications and models: Sand making machines have a variety of models, and different specifications and models are suitable for different production needs. Larger equipment is usually suitable for large-scale production, and the price is naturally higher; while small and medium-sized equipment is more suitable for small-scale sand and gravel plants, and the price is relatively cheap.

Quality and performance: The quality of equipment directly affects its production efficiency and service life. High-quality equipment is more expensive, but it has stable operation and low failure rate, which can bring higher return on investment. Conversely, poor-quality equipment is cheap, but may increase the cost of later repairs and replacements.

Production demand and output: The higher the output demand of the production line, the more equipment is required, and the cost will naturally increase. Therefore, the greater the output demand, the higher the overall price of the production line.

Supply and demand relationship: Changes in market supply and demand will also affect prices. When demand is high and supply is insufficient, equipment prices may rise; conversely, they may fall.

2. Types and prices of sand making equipment

Different types of sand making equipment have large price differences. The following are several common sand making machines and their price ranges:

VSI sand making machine: It is a traditional sand making equipment suitable for medium-sized production lines, and the price is about 200,000-800,000.

VSI5X sand making machine: It adopts German technology, has high crushing efficiency and longer service life, and the price is generally between 300,000 and 1.2 million.

VSI6X sand making machine: a new generation of high-efficiency and low-cost sand making and shaping equipment, with a price range of approximately RMB 200,000 to RMB 1.5 million.

3. Complete configuration of sand making production line

Sand making production line is not just a single sand making machine, it usually includes a combination of multiple equipment, and the specific configuration depends on the output demand. Common sand making production line configurations include:

Vibrating feeder: feeds the material evenly into the crusher.

Crushing equipment: such as jaw crusher, cone crusher, impact crusher, etc., for coarse and medium crushing.

Sand making machine: used to process the crushed material into machine-made sand that meets market demand.

Vibrating screen: screens the material after sand making to ensure the particle size of the finished product.

Sand washing machine: used to clean machine-made sand, remove impurities, and improve the quality of the finished product.

Conveying equipment: such as belt conveyor, used to transport materials between different equipment.

The equipment selection and configuration of the entire production line will directly affect the overall investment cost. Generally speaking, the price of a small sand production line is between 500,000 and 1 million, while the price of a large-scale production line may be as high as 3 million or more.

4. How to choose a suitable sand making machine?

Choose the model according to production needs: The scale, output and type of sand and gravel required of the production line determine the choice of sand making machine. Small plants can choose HX series equipment, while large-scale sand plants are more suitable for VSI or VSI5X series.

Pay attention to cost performance and after-sales service: When purchasing sand making equipment, you should not only consider the price of the equipment, but also pay attention to the cost performance of the equipment and the after-sales service provided by the manufacturer. High-quality after-sales service can reduce the cost of later maintenance and ensure the long-term stable operation of the production line.

Consult professional manufacturers: Choose well-known and reputable manufacturers who can customize the production line according to the actual needs of customers to ensure that the equipment is highly matched with production needs.

5. Return on investment of sand production line

Although the initial investment of sand production line is large, its return on investment period is usually short. Efficient and stable production lines can greatly improve production efficiency and reduce production costs. Therefore, under the premise of reasonable configuration, in the long run, the return on investment of machine-made sand production line is very considerable.

In summary, the price of sand making machine is affected by multiple factors, usually between 500,000 and 3 million. According to different market demands, choosing the right equipment and configuration can effectively improve production efficiency and achieve a good return on investment. If you plan to invest in a sand making production line, it is recommended to consult professional manufacturers and obtain accurate quotes based on your own needs, production scale and budget.

Previous: SMP Crusher

Next: SMP Crusher

How to build a high-yield sand production line

How to build a high-yield sand production line How much does a mobile crusher with an output of 100/150/300 tons per hour cost?

How much does a mobile crusher with an output of 100/150/300 tons per hour cost? Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste

Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste 500 tons per hour sand making machine price

500 tons per hour sand making machine price How to choose equipment for crushing and reusing old cement pavement

How to choose equipment for crushing and reusing old cement pavement How to build a high-yield sand production line

How to build a high-yield sand production line How much does a mobile crusher with an output of 100/150/300 tons per hour cost?

How much does a mobile crusher with an output of 100/150/300 tons per hour cost? Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste

Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste 500 tons per hour sand making machine price

500 tons per hour sand making machine price How to choose equipment for crushing and reusing old cement pavement

How to choose equipment for crushing and reusing old cement pavement