Lead-zinc ore is a mineral rich in lead and zinc, which often coexists in the same ore. According to the properties and composition of the ore, it can be divided into many types such as sulfide lead-zinc ore and oxide lead-zinc ore. In China, lead-zinc

Lead-zinc ore is a mineral rich in lead and zinc, which often coexists in the same ore. According to the properties and composition of the ore, it can be divided into many types such as sulfide lead-zinc ore and oxide lead-zinc ore. In China, lead-zinc ore resources are mainly distributed in Yunnan, Inner Mongolia, Gansu, Guangdong, Hunan and Guangxi. Lead-zinc ore processing process:

Lead-zinc ore processing process and equipment click to consult

Lead-zinc ore processing mainly includes three processes: crushing, grinding and beneficiation.

First stage: crushing and screening-three-stage closed-circuit crushing

Large pieces of lead-zinc ore are first fed into the silo, and then evenly and continuously fed into the jaw crusher through a vibrating feeder for preliminary coarse crushing. The coarsely crushed ore particles are finely screened by the vibrating screen to separate gravel of different sizes. The ore of qualified particle size is then smoothly and efficiently conveyed to the single-cylinder hydraulic cone crusher by the belt conveyor for further medium crushing. After medium crushing, the ore is sent to the multi-cylinder hydraulic cone crusher again for the final fine crushing operation to obtain smaller and more uniform ore particles to meet the needs of subsequent processing or use.

Crushing lead-zinc ore can be selected from: jaw crusher, cone crusher and impact crusher, etc.

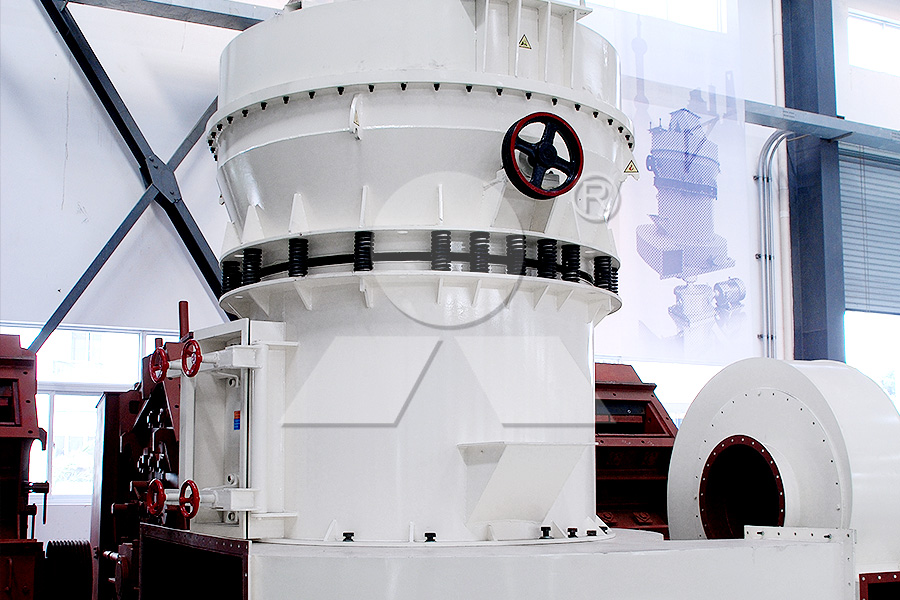

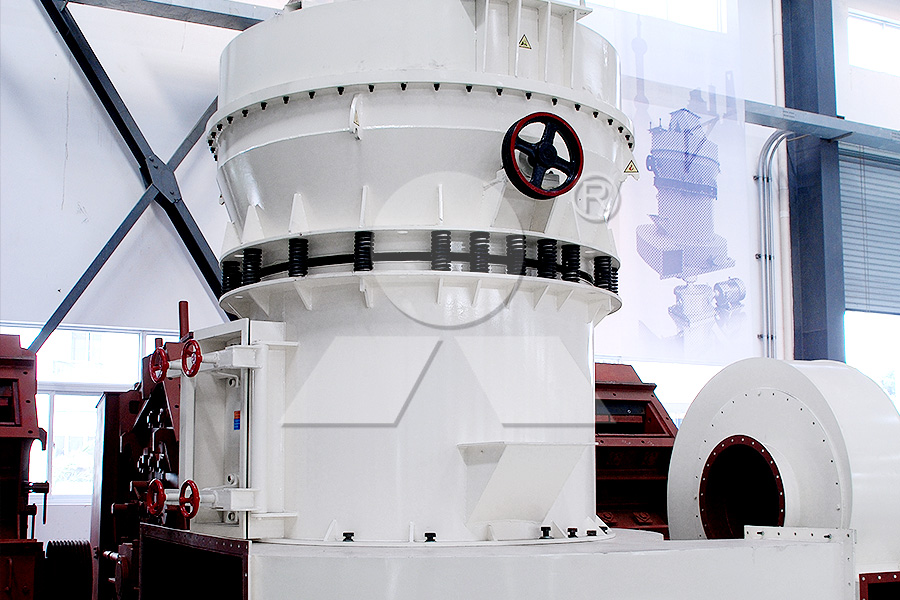

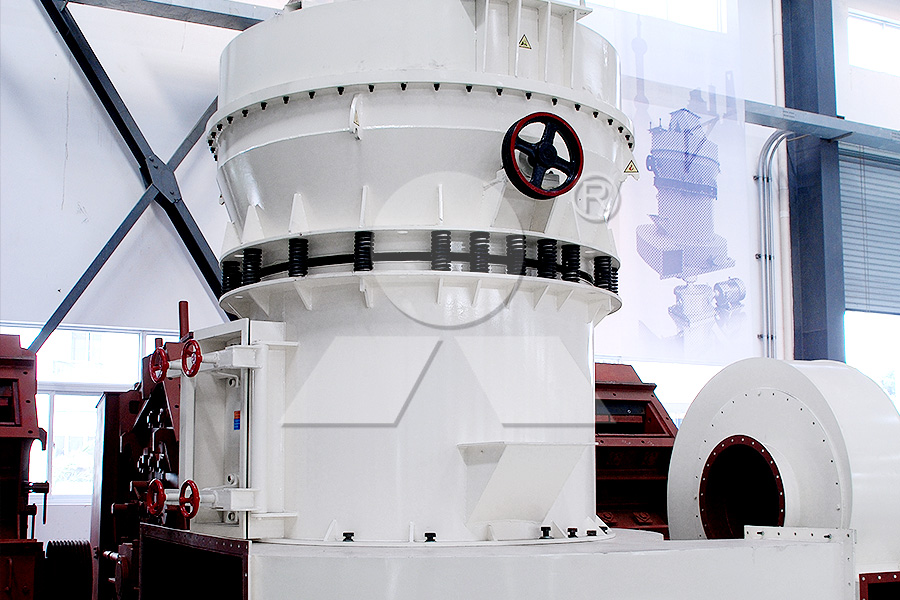

Second stage: grinding

The 0-12 mm lead-zinc ore is evenly fed into the grinding machine for grinding. After screening by the spiral classifier, the ore that does not meet the requirements is returned for re-grinding.

Third stage: ore dressing

The powder ore that meets the ore dressing requirements is sent to the magnetic separator for strong magnetic separation to remove impurities, and the obtained ore powder is sent to the dryer for drying to obtain the concentrate.

Previous: SMP Crusher

Next: SMP Crusher

Lead-zinc ore is a mineral rich in lead and zinc, which often coexists in the same ore. According to the properties and composition of the ore, it can be divided into many types such as sulfide lead-zinc ore and oxide lead-zinc ore. In China, lead-zinc

Lead-zinc ore is a mineral rich in lead and zinc, which often coexists in the same ore. According to the properties and composition of the ore, it can be divided into many types such as sulfide lead-zinc ore and oxide lead-zinc ore. In China, lead-zinc ore resources are mainly distributed in Yunnan, Inner Mongolia, Gansu, Guangdong, Hunan and Guangxi. Lead-zinc ore processing process:

Lead-zinc ore processing process and equipment click to consult

Lead-zinc ore processing mainly includes three processes: crushing, grinding and beneficiation.

First stage: crushing and screening-three-stage closed-circuit crushing

Large pieces of lead-zinc ore are first fed into the silo, and then evenly and continuously fed into the jaw crusher through a vibrating feeder for preliminary coarse crushing. The coarsely crushed ore particles are finely screened by the vibrating screen to separate gravel of different sizes. The ore of qualified particle size is then smoothly and efficiently conveyed to the single-cylinder hydraulic cone crusher by the belt conveyor for further medium crushing. After medium crushing, the ore is sent to the multi-cylinder hydraulic cone crusher again for the final fine crushing operation to obtain smaller and more uniform ore particles to meet the needs of subsequent processing or use.

Crushing lead-zinc ore can be selected from: jaw crusher, cone crusher and impact crusher, etc.

Second stage: grinding

The 0-12 mm lead-zinc ore is evenly fed into the grinding machine for grinding. After screening by the spiral classifier, the ore that does not meet the requirements is returned for re-grinding.

Third stage: ore dressing

The powder ore that meets the ore dressing requirements is sent to the magnetic separator for strong magnetic separation to remove impurities, and the obtained ore powder is sent to the dryer for drying to obtain the concentrate.

Previous: SMP Crusher

Next: SMP Crusher

How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced? How to improve the service life of impact sand making machine

How to improve the service life of impact sand making machine How to clean the inside of cone crusher

How to clean the inside of cone crusher What are the differences between coarse jaw crusher and fine jaw crusher?

What are the differences between coarse jaw crusher and fine jaw crusher? Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone

Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced? How to improve the service life of impact sand making machine

How to improve the service life of impact sand making machine How to clean the inside of cone crusher

How to clean the inside of cone crusher What are the differences between coarse jaw crusher and fine jaw crusher?

What are the differences between coarse jaw crusher and fine jaw crusher? Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone

Why is multi-cylinder hydraulic cone crusher suitable for high hardness stone