In the processing of basalt, the crushing stage is crucial and a crusher is required. In the medium and fine crushing stage, the cone crusher is an ideal choice. This equipment is designed for processing high-hardness materials and is very suitable for

In the processing of basalt, the crushing stage is crucial and a crusher is required. In the medium and fine crushing stage, the cone crusher is an ideal choice. This equipment is designed for processing high-hardness materials and is very suitable for basalt processing. Different crushers need to be selected for different crushing stages to ensure processing efficiency and effect. There are also many types of cone crushing equipment. When medium and fine crushing of this kind of material, which one is more suitable?

Click to consult to learn about basalt crushing equipment

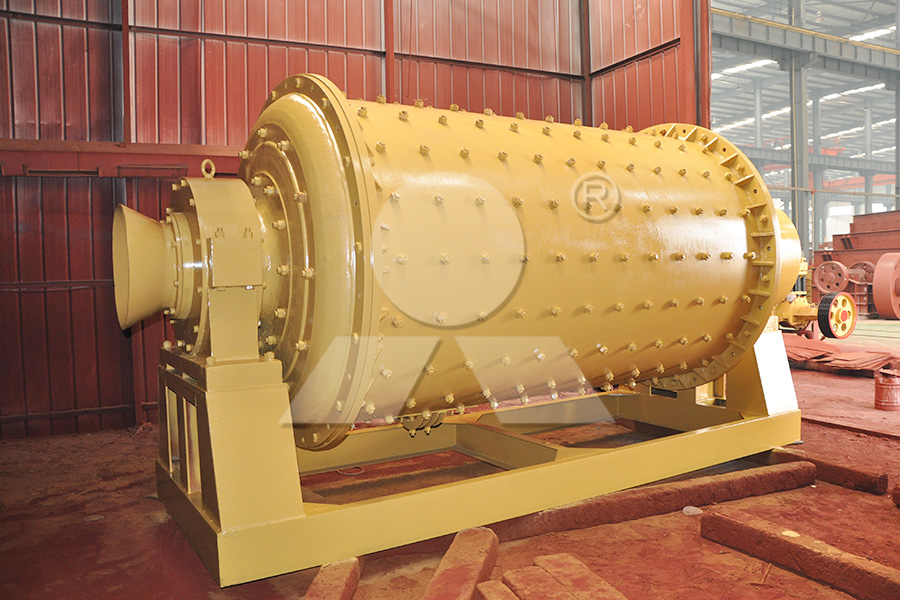

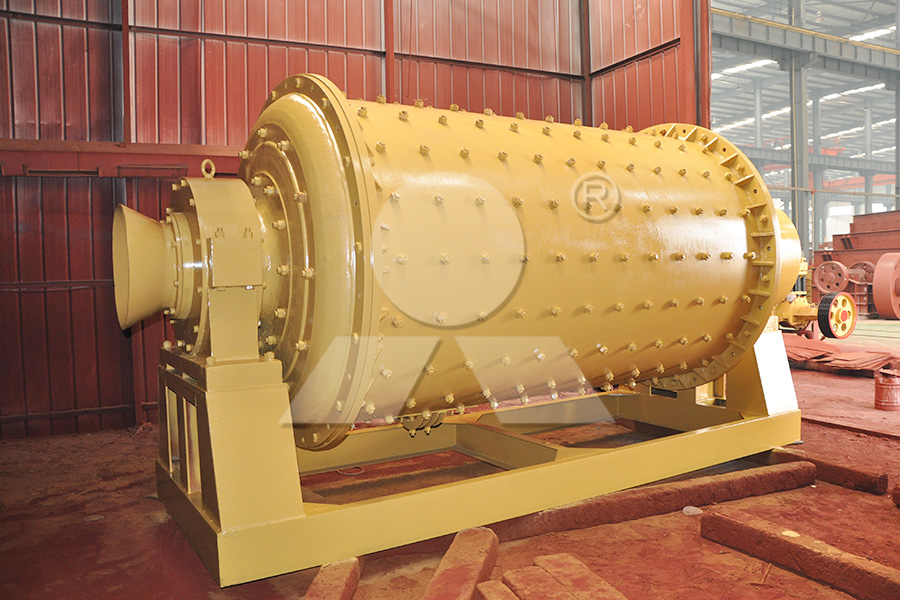

Due to its excellent performance, basalt has become an important source of stone for the construction of roads, railways, airport runways, etc. Its processing process not only pursues high efficiency, but also requires excellent finished product particle shape. Multi-cylinder hydraulic cone crusher is widely used in this field. The machine has undergone structural improvements on the traditional basis and its performance has been significantly improved. Its supporting hydraulic lubrication system not only ensures the reliable operation of the equipment, but also realizes more intelligent and humanized operation control. In addition, the machine has strong carrying capacity, small size, high efficiency and low noise. It can not only meet production capacity requirements, but also meet environmental protection requirements. It is an ideal choice for basalt processing.

However, there are many models of multi-cylinder hydraulic cone crushers. When processing basalt, you need to choose a suitable model. When choosing a specific model, there are many factors to refer to, such as the feed size of basalt, the production capacity requirements, the finished product particle size requirements, etc. In addition, it will also involve cost investment requirements, after-sales and other aspects. Only by comprehensively considering these aspects can you choose the appropriate production equipment.

Previous: SMP Crusher

Next: SMP Crusher

In the processing of basalt, the crushing stage is crucial and a crusher is required. In the medium and fine crushing stage, the cone crusher is an ideal choice. This equipment is designed for processing high-hardness materials and is very suitable for

In the processing of basalt, the crushing stage is crucial and a crusher is required. In the medium and fine crushing stage, the cone crusher is an ideal choice. This equipment is designed for processing high-hardness materials and is very suitable for basalt processing. Different crushers need to be selected for different crushing stages to ensure processing efficiency and effect. There are also many types of cone crushing equipment. When medium and fine crushing of this kind of material, which one is more suitable?

Click to consult to learn about basalt crushing equipment

Due to its excellent performance, basalt has become an important source of stone for the construction of roads, railways, airport runways, etc. Its processing process not only pursues high efficiency, but also requires excellent finished product particle shape. Multi-cylinder hydraulic cone crusher is widely used in this field. The machine has undergone structural improvements on the traditional basis and its performance has been significantly improved. Its supporting hydraulic lubrication system not only ensures the reliable operation of the equipment, but also realizes more intelligent and humanized operation control. In addition, the machine has strong carrying capacity, small size, high efficiency and low noise. It can not only meet production capacity requirements, but also meet environmental protection requirements. It is an ideal choice for basalt processing.

However, there are many models of multi-cylinder hydraulic cone crushers. When processing basalt, you need to choose a suitable model. When choosing a specific model, there are many factors to refer to, such as the feed size of basalt, the production capacity requirements, the finished product particle size requirements, etc. In addition, it will also involve cost investment requirements, after-sales and other aspects. Only by comprehensively considering these aspects can you choose the appropriate production equipment.

Previous: SMP Crusher

Next: SMP Crusher

What is the production effect of basalt sand making machine?

What is the production effect of basalt sand making machine? How to choose a 200 tons per hour iron ore mobile crushing station

How to choose a 200 tons per hour iron ore mobile crushing station What are the reasons for the shaking of jaw crusher?

What are the reasons for the shaking of jaw crusher? How to replace the crushing wall of cone crusher

How to replace the crushing wall of cone crusher What factors are related to the replacement time of crusher wearing parts?

What factors are related to the replacement time of crusher wearing parts? What is the production effect of basalt sand making machine?

What is the production effect of basalt sand making machine? How to choose a 200 tons per hour iron ore mobile crushing station

How to choose a 200 tons per hour iron ore mobile crushing station What are the reasons for the shaking of jaw crusher?

What are the reasons for the shaking of jaw crusher? How to replace the crushing wall of cone crusher

How to replace the crushing wall of cone crusher What factors are related to the replacement time of crusher wearing parts?

What factors are related to the replacement time of crusher wearing parts?