The advantages and equipment selection of the 500 tons per hour machine-made sand equipment production line are as follows:Click here to consult to learn how to build a machine-made sand production line and equipment selection

The advantages and equipment selection of the 500 tons per hour machine-made sand equipment production line are as follows:

Click here to consult to learn how to build a machine-made sand production line and equipment selection

Project Overview

Raw materials: granite

Output: 450-500 tons/hour

Application: highways, high-speed railways, mixing stations

Project Advantages

1. Optimized host, finished products meet standards

The production line is equipped with a new sand making machine that adopts the stone-on-stone working principle. This equipment has significant advantages. It can not only ensure the good particle shape of the finished sand, but also ensure the rationality of the gradation, which fully meets the strict requirements of the surrounding high-standard projects on the particle shape and gradation of the sand.

2. Optimize the design and reduce operating costs

The host equipment adopts a full thin oil lubrication method. This design is very considerate. There is no need for manual refueling every shift. Daily maintenance and repair are easy and labor-saving, which effectively saves labor costs. At the same time, the stone-on-stone working method it uses greatly reduces the loss of equipment wear-resistant parts, while ensuring production, it effectively reduces production and operation costs.

3. Full-process configuration, high production efficiency

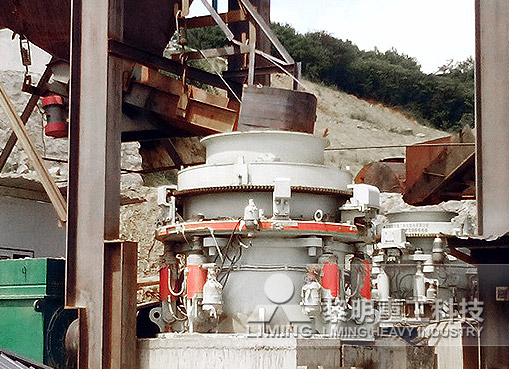

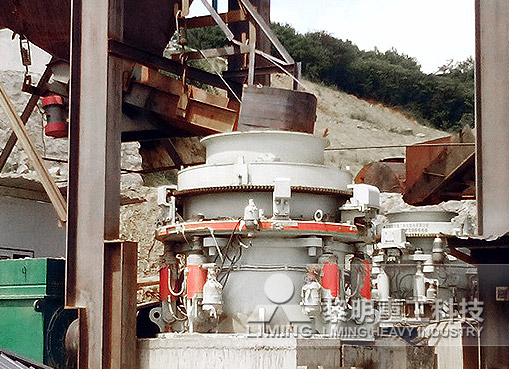

The production line's primary crushing, secondary crushing and shaping sand making main equipment. The C6X jaw crusher is used for primary crushing, the single-cylinder hydraulic cone crusher is used for secondary crushing, and the VSI6X impact sand making machine is used for shaping sand making. The advantages of the equipment combination are fully demonstrated, with high production efficiency and strong carrying capacity.

4. Flexible adjustment, sand and gravel are produced at the same time

This production line can not only be used for full sand production, but also sand and gravel can be produced at the same time. It can be flexibly adjusted according to market demand.

Equipment configuration

C6X jaw crusher HST single-cylinder hydraulic cone crusher VSI6X vertical shaft impact crusher S5X vibration screening equipment

Previous: SMP Crusher

Next: SMP Crusher

The advantages and equipment selection of the 500 tons per hour machine-made sand equipment production line are as follows:Click here to consult to learn how to build a machine-made sand production line and equipment selection

The advantages and equipment selection of the 500 tons per hour machine-made sand equipment production line are as follows:

Click here to consult to learn how to build a machine-made sand production line and equipment selection

Project Overview

Raw materials: granite

Output: 450-500 tons/hour

Application: highways, high-speed railways, mixing stations

Project Advantages

1. Optimized host, finished products meet standards

The production line is equipped with a new sand making machine that adopts the stone-on-stone working principle. This equipment has significant advantages. It can not only ensure the good particle shape of the finished sand, but also ensure the rationality of the gradation, which fully meets the strict requirements of the surrounding high-standard projects on the particle shape and gradation of the sand.

2. Optimize the design and reduce operating costs

The host equipment adopts a full thin oil lubrication method. This design is very considerate. There is no need for manual refueling every shift. Daily maintenance and repair are easy and labor-saving, which effectively saves labor costs. At the same time, the stone-on-stone working method it uses greatly reduces the loss of equipment wear-resistant parts, while ensuring production, it effectively reduces production and operation costs.

3. Full-process configuration, high production efficiency

The production line's primary crushing, secondary crushing and shaping sand making main equipment. The C6X jaw crusher is used for primary crushing, the single-cylinder hydraulic cone crusher is used for secondary crushing, and the VSI6X impact sand making machine is used for shaping sand making. The advantages of the equipment combination are fully demonstrated, with high production efficiency and strong carrying capacity.

4. Flexible adjustment, sand and gravel are produced at the same time

This production line can not only be used for full sand production, but also sand and gravel can be produced at the same time. It can be flexibly adjusted according to market demand.

Equipment configuration

C6X jaw crusher HST single-cylinder hydraulic cone crusher VSI6X vertical shaft impact crusher S5X vibration screening equipment

Previous: SMP Crusher

Next: SMP Crusher

Sichuan 150-250 tons per hour river pebble sand production line: Shibang equipment combines high efficiency and quality

Sichuan 150-250 tons per hour river pebble sand production line: Shibang equipment combines high efficiency and quality Is it better to choose single cylinder or multi-cylinder cone crusher?

Is it better to choose single cylinder or multi-cylinder cone crusher? Investing 168 million yuan, Shandong Yantai sand and gravel aggregate project: Shibang helps build an efficient and high-quality production line

Investing 168 million yuan, Shandong Yantai sand and gravel aggregate project: Shibang helps build an efficient and high-quality production line Which crushing equipment is suitable for soft rock crushing?

Which crushing equipment is suitable for soft rock crushing? Comparison of Shaping Functions between Impact Crusher and Vertical Shaft Crusher

Comparison of Shaping Functions between Impact Crusher and Vertical Shaft Crusher Sichuan 150-250 tons per hour river pebble sand production line: Shibang equipment combines high efficiency and quality

Sichuan 150-250 tons per hour river pebble sand production line: Shibang equipment combines high efficiency and quality Is it better to choose single cylinder or multi-cylinder cone crusher?

Is it better to choose single cylinder or multi-cylinder cone crusher? Investing 168 million yuan, Shandong Yantai sand and gravel aggregate project: Shibang helps build an efficient and high-quality production line

Investing 168 million yuan, Shandong Yantai sand and gravel aggregate project: Shibang helps build an efficient and high-quality production line Which crushing equipment is suitable for soft rock crushing?

Which crushing equipment is suitable for soft rock crushing? Comparison of Shaping Functions between Impact Crusher and Vertical Shaft Crusher

Comparison of Shaping Functions between Impact Crusher and Vertical Shaft Crusher