Luoyang Dahua Heavy Industry's environmentally friendly EPC slag comprehensive recycling project with an annual output of 150,000 tons in a steel plant in Xingtai, Hebei.Material: waste steel slagOutput value:

Luoyang Dahua Heavy Industry's environmentally friendly EPC slag comprehensive recycling project with an annual output of 150,000 tons in a steel plant in Xingtai, Hebei.

Material: waste steel slag

Output value: 150,000 tons per year

The main equipment equipped with the production line are:

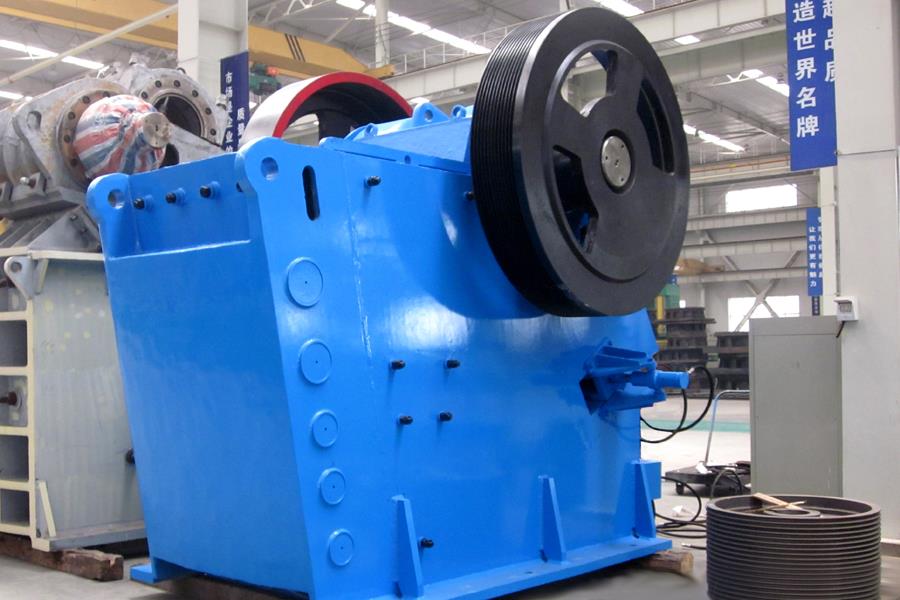

PEY series hydraulic protection jaw crusher for steel slag;

GMBZ series high-efficiency and energy-saving rod mill for steel slag;

2YKR series vibrating screen and magnetic separator for steel slag and other related main equipment and supporting equipment.

Process advantage description:

PEY series hydraulic protection jaw crusher for steel slag

Product features

The rated load of the machine can be set arbitrarily, which can be used for selective crushing of materials with different compressive strengths.

Reliable protection, automatic discharge of unbreakable materials, effectively solving the "steel stuck" problem in steel slag crushing.

Automatic reset after iron discharge, can achieve continuous production without stopping.

The single hydraulic cylinder supported by the hydraulic station can not only adjust the size of the discharge port, but also unload and discharge the unbreakable materials.

It will not produce asynchronism like the double-acting cylinder, causing the segregation of the movable jaw and damaging the machine body.

It comes with a hydraulic station and PLC automatic control system.

GMBZ series steel slag high-efficiency and energy-saving rod mill

Product features

The special discharging structure and environmental protection measures ensure uniform discharging, large discharging volume and low pollution.

The special feeder feeds the material with a large feeding volume. The equipment is equipped with auxiliary machines such as slow drive device and dry oil injection device. It can also be configured according to user requirements, and can be designed and manufactured as non-standard.

The crushing ratio is large and the purification effect is good.

Rolling bearing support saves 10~20% energy.

The equipment is easy to operate and the structure is stable and reliable.

The production line is equipped with an advanced central control system to monitor the operation and start and stop of the equipment, ensure the efficient, stable and safe operation of the production line, and escort safe production. In addition, the production line is equipped with a reliable environmental dust removal system, so that the production site can maintain a good working environment, which is also in response to the country's call for environmental protection and to achieve environmentally friendly production. According to the distribution location of the customer's workshop, our company inspected the site and designed a scientific and reasonable process according to local conditions. The humanized design also greatly improved the production efficiency of the production line and the space utilization rate of the production workshop.

Previous: SMP Crusher

Next: SMP Crusher

Luoyang Dahua Heavy Industry's environmentally friendly EPC slag comprehensive recycling project with an annual output of 150,000 tons in a steel plant in Xingtai, Hebei.Material: waste steel slagOutput value:

Luoyang Dahua Heavy Industry's environmentally friendly EPC slag comprehensive recycling project with an annual output of 150,000 tons in a steel plant in Xingtai, Hebei.

Material: waste steel slag

Output value: 150,000 tons per year

The main equipment equipped with the production line are:

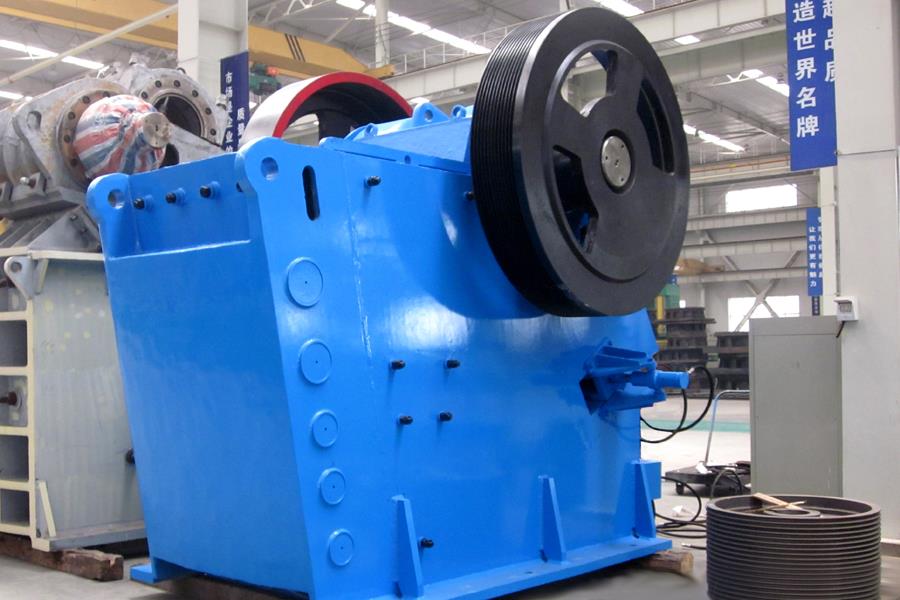

PEY series hydraulic protection jaw crusher for steel slag;

GMBZ series high-efficiency and energy-saving rod mill for steel slag;

2YKR series vibrating screen and magnetic separator for steel slag and other related main equipment and supporting equipment.

Process advantage description:

PEY series hydraulic protection jaw crusher for steel slag

Product features

The rated load of the machine can be set arbitrarily, which can be used for selective crushing of materials with different compressive strengths.

Reliable protection, automatic discharge of unbreakable materials, effectively solving the "steel stuck" problem in steel slag crushing.

Automatic reset after iron discharge, can achieve continuous production without stopping.

The single hydraulic cylinder supported by the hydraulic station can not only adjust the size of the discharge port, but also unload and discharge the unbreakable materials.

It will not produce asynchronism like the double-acting cylinder, causing the segregation of the movable jaw and damaging the machine body.

It comes with a hydraulic station and PLC automatic control system.

GMBZ series steel slag high-efficiency and energy-saving rod mill

Product features

The special discharging structure and environmental protection measures ensure uniform discharging, large discharging volume and low pollution.

The special feeder feeds the material with a large feeding volume. The equipment is equipped with auxiliary machines such as slow drive device and dry oil injection device. It can also be configured according to user requirements, and can be designed and manufactured as non-standard.

The crushing ratio is large and the purification effect is good.

Rolling bearing support saves 10~20% energy.

The equipment is easy to operate and the structure is stable and reliable.

The production line is equipped with an advanced central control system to monitor the operation and start and stop of the equipment, ensure the efficient, stable and safe operation of the production line, and escort safe production. In addition, the production line is equipped with a reliable environmental dust removal system, so that the production site can maintain a good working environment, which is also in response to the country's call for environmental protection and to achieve environmentally friendly production. According to the distribution location of the customer's workshop, our company inspected the site and designed a scientific and reasonable process according to local conditions. The humanized design also greatly improved the production efficiency of the production line and the space utilization rate of the production workshop.

Previous: SMP Crusher

Next: SMP Crusher

Anhui 2000 tons per hour granite production line

Anhui 2000 tons per hour granite production line Shanxi Jincheng 600tph limestone production line

Shanxi Jincheng 600tph limestone production line Yunnan 2000 tons construction sand and gravel aggregate production line

Yunnan 2000 tons construction sand and gravel aggregate production line Cameroon 200 tons per hour dam sand and gravel aggregate processing production line

Cameroon 200 tons per hour dam sand and gravel aggregate processing production line Tibet 200 tons per hour construction sand and gravel aggregate production line

Tibet 200 tons per hour construction sand and gravel aggregate production line Anhui 2000 tons per hour granite production line

Anhui 2000 tons per hour granite production line Shanxi Jincheng 600tph limestone production line

Shanxi Jincheng 600tph limestone production line Yunnan 2000 tons construction sand and gravel aggregate production line

Yunnan 2000 tons construction sand and gravel aggregate production line Cameroon 200 tons per hour dam sand and gravel aggregate processing production line

Cameroon 200 tons per hour dam sand and gravel aggregate processing production line Tibet 200 tons per hour construction sand and gravel aggregate production line

Tibet 200 tons per hour construction sand and gravel aggregate production line