In the fine machine-made sand production industry, which raw materials are more popular for making sand? Basalt, granite, river pebbles and other hard rock sand making. The following article takes basalt sand making as an example to explain the basalt

In the fine machine-made sand production industry, which raw materials are more popular for making sand? Basalt, granite, river pebbles and other hard rock sand making. The following article takes basalt sand making as an example to explain the basalt sand making production plan in detail:

Sand and gravel production line construction plan click to consult

Detailed explanation of basalt sand making production line plan

Basalt is a key component of the continental crust. It is widely distributed and rich in resources. Especially in the construction industry, it is famous for its processed machine-made sand. Because of its hard texture, wear resistance and strong pressure resistance, basalt is regarded as a high-quality sand making raw material. However, these excellent properties bring challenges to the crushing and sand making process. In order to make full use of the advantages of basalt, the key problem that needs to be solved urgently is how to overcome the crushing problem caused by its hard and wear-resistant characteristics, so as to optimize the production process and improve the quality and output of machine-made sand.

With the continuous advancement of science and technology, there are many sand making equipment and sand making equipment production lines specially launched for hard rock processing and production in the fine machine-made sand market. The common basalt sand production line process is generally divided into three processes, namely coarse crushing-medium crushing-sand making (shaping).

The entire production process is mainly composed of feeder, jaw crusher, belt conveyor, cone crusher, vibrating screen, sand making machine, and sand washing machine.

Process flow of sand production line for hard rock materials such as basalt

After the basalt stone material is sent to the jaw crushing station for coarse crushing by the feeder, it is conveyed to the cone crusher for further crushing by the belt conveyor. The qualified aggregates are processed in the sand making machine, and the unqualified ones are returned to the cone crusher for re-crushing. The finished sand making product is screened by the vibrating screen, and the unqualified ones are returned to the sand making machine for reprocessing. The qualified powder is cleaned by the sand washing machine and finally sent to the finished product pile. The whole process realizes the efficient and fine processing of basalt stone materials and ensures the quality of the finished product.

To build a high-quality basalt sand making equipment production line, the selection of machine-made sand equipment is the key

Since the volume of basalt stone is generally large, the jaw crusher with large feed particle size and high compressive strength is used as the first crusher. It not only has a large crushing ratio and high production capacity, but also has uniform finished product particle shape, which provides strong material guarantee for subsequent crushing work.

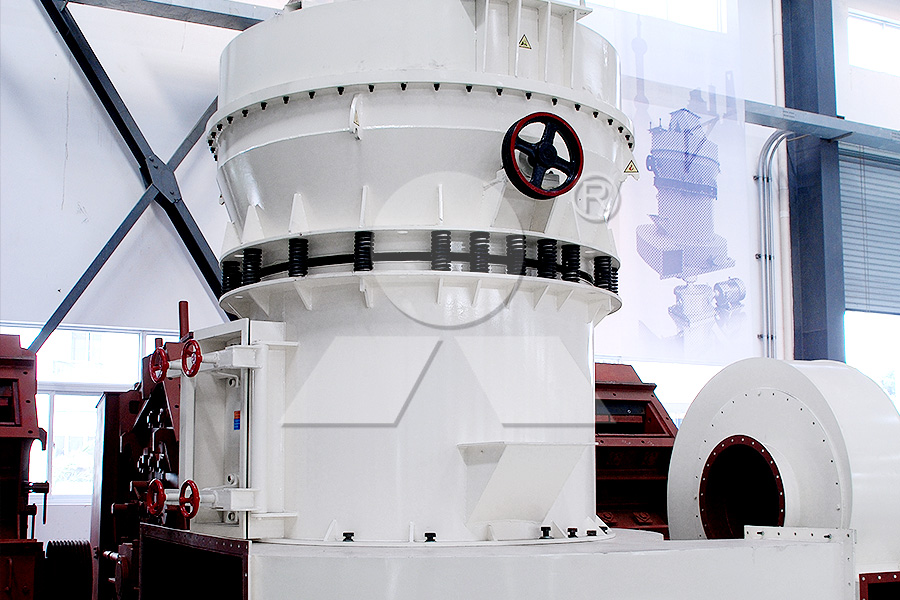

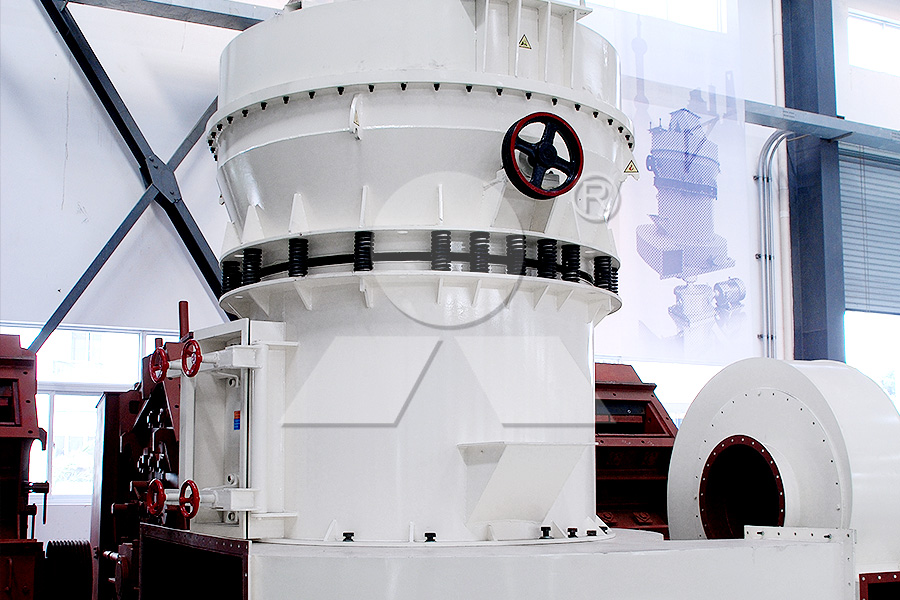

Shibang cone crusher uses the principle of lamination crushing to optimize the product particle shape and make it present a cubic shape. The equipment has high efficiency, low cost, produces fine particle shape, and operates stably and reliably. It is an ideal choice for processing medium-hardness materials, especially suitable for the second and third stage crushing processes to ensure the excellent performance of the crushing process.

As a product in the field of sand making, Shibang Group's sand making equipment not only has the characteristics of energy saving, long service life, and wide application, but also integrates sand making and shaping. The finished product particle shape is mostly cubic, with low needle-like content, and excellent quality to meet the needs of the market for high-quality machine-made sand.

Previous: SMP Crusher

Next: SMP Crusher

In the fine machine-made sand production industry, which raw materials are more popular for making sand? Basalt, granite, river pebbles and other hard rock sand making. The following article takes basalt sand making as an example to explain the basalt

In the fine machine-made sand production industry, which raw materials are more popular for making sand? Basalt, granite, river pebbles and other hard rock sand making. The following article takes basalt sand making as an example to explain the basalt sand making production plan in detail:

Sand and gravel production line construction plan click to consult

Detailed explanation of basalt sand making production line plan

Basalt is a key component of the continental crust. It is widely distributed and rich in resources. Especially in the construction industry, it is famous for its processed machine-made sand. Because of its hard texture, wear resistance and strong pressure resistance, basalt is regarded as a high-quality sand making raw material. However, these excellent properties bring challenges to the crushing and sand making process. In order to make full use of the advantages of basalt, the key problem that needs to be solved urgently is how to overcome the crushing problem caused by its hard and wear-resistant characteristics, so as to optimize the production process and improve the quality and output of machine-made sand.

With the continuous advancement of science and technology, there are many sand making equipment and sand making equipment production lines specially launched for hard rock processing and production in the fine machine-made sand market. The common basalt sand production line process is generally divided into three processes, namely coarse crushing-medium crushing-sand making (shaping).

The entire production process is mainly composed of feeder, jaw crusher, belt conveyor, cone crusher, vibrating screen, sand making machine, and sand washing machine.

Process flow of sand production line for hard rock materials such as basalt

After the basalt stone material is sent to the jaw crushing station for coarse crushing by the feeder, it is conveyed to the cone crusher for further crushing by the belt conveyor. The qualified aggregates are processed in the sand making machine, and the unqualified ones are returned to the cone crusher for re-crushing. The finished sand making product is screened by the vibrating screen, and the unqualified ones are returned to the sand making machine for reprocessing. The qualified powder is cleaned by the sand washing machine and finally sent to the finished product pile. The whole process realizes the efficient and fine processing of basalt stone materials and ensures the quality of the finished product.

To build a high-quality basalt sand making equipment production line, the selection of machine-made sand equipment is the key

Since the volume of basalt stone is generally large, the jaw crusher with large feed particle size and high compressive strength is used as the first crusher. It not only has a large crushing ratio and high production capacity, but also has uniform finished product particle shape, which provides strong material guarantee for subsequent crushing work.

Shibang cone crusher uses the principle of lamination crushing to optimize the product particle shape and make it present a cubic shape. The equipment has high efficiency, low cost, produces fine particle shape, and operates stably and reliably. It is an ideal choice for processing medium-hardness materials, especially suitable for the second and third stage crushing processes to ensure the excellent performance of the crushing process.

As a product in the field of sand making, Shibang Group's sand making equipment not only has the characteristics of energy saving, long service life, and wide application, but also integrates sand making and shaping. The finished product particle shape is mostly cubic, with low needle-like content, and excellent quality to meet the needs of the market for high-quality machine-made sand.

Previous: SMP Crusher

Next: SMP Crusher

What equipment is used to crush granite into sand

What equipment is used to crush granite into sand Which equipment to use for crushing iron ore

Which equipment to use for crushing iron ore What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore? How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced? How to improve the service life of impact sand making machine

How to improve the service life of impact sand making machine What equipment is used to crush granite into sand

What equipment is used to crush granite into sand Which equipment to use for crushing iron ore

Which equipment to use for crushing iron ore What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore? How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced? How to improve the service life of impact sand making machine

How to improve the service life of impact sand making machine