The first step in iron ore processing is crushing, which aims to crush large pieces of iron ore to the required particle size for subsequent grinding and beneficiation. In view of the high hardness of iron ore, the principle of "more crushing and

The first step in iron ore processing is crushing, which aims to crush large pieces of iron ore to the required particle size for subsequent grinding and beneficiation. In view of the high hardness of iron ore, the principle of "more crushing and less grinding" should be followed, and a three-stage one-closed-circuit crushing mode should be adopted to efficiently complete the crushing operation.

Click here to consult iron ore equipment selection

1. Coarse crushing: jaw crusher or gyratory crusher

The large pieces of ore are first crushed to medium size by jaw crusher or gyratory crusher, laying the foundation for the subsequent medium and fine crushing. Jaw crusher is the first choice for coarse crushing of most ores due to its wide versatility; while gyratory crusher is more suitable for large metal mining projects, with high production capacity and an hourly output of more than 2,000 tons.

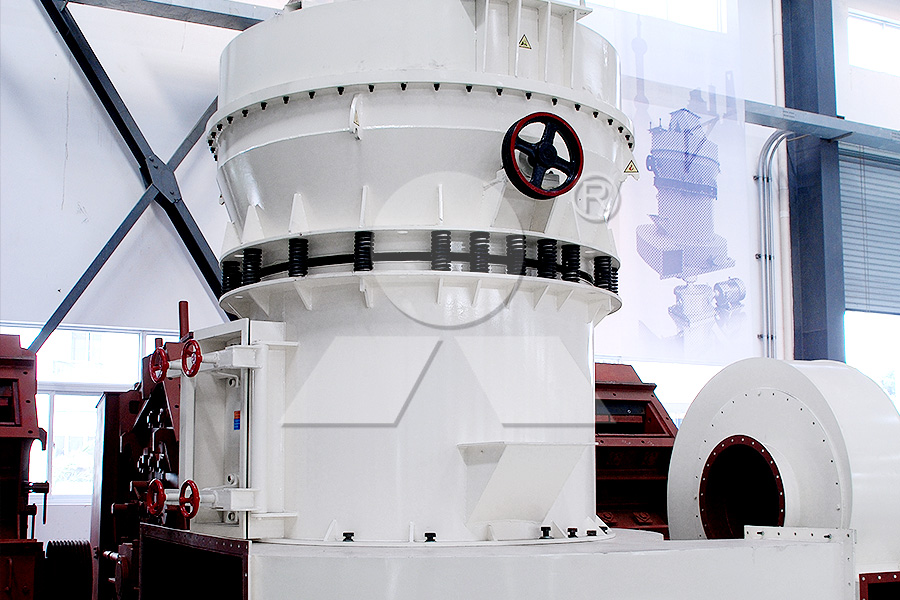

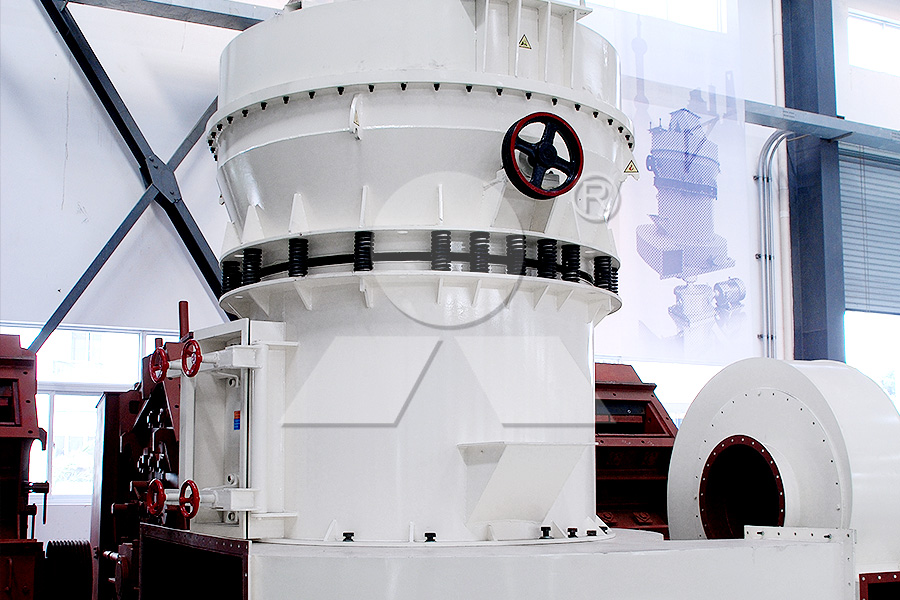

2. Medium crushing: standard cone crusher

The iron ore treated by jaw crusher is sent to standard cone crusher for further fine crushing. The single-cylinder hydraulic cone crusher is the preferred equipment. Its hydraulic system has better performance than the spring system, which can significantly improve the crushing efficiency and output, and simplify the subsequent maintenance work, which is more advantageous.

3. Fine crushing link: short-head cone crusher

The iron ore after medium crushing is sent to the short-head cone crusher for further fine crushing. The representative equipment can be selected as a multi-cylinder hydraulic cone crusher, which has different crushing chamber types such as coarse, medium, fine, and ultra-fine. The discharge range can reach 6-38mm, and the output fine material can be directly sent to the grinding equipment.

This is a classic configuration for iron ore crushing, and the equipment can be increased or decreased according to actual production needs. You can also choose a flexible mobile crushing station according to the production scale and working conditions of different projects.

Previous: SMP Crusher

Next: SMP Crusher

The first step in iron ore processing is crushing, which aims to crush large pieces of iron ore to the required particle size for subsequent grinding and beneficiation. In view of the high hardness of iron ore, the principle of "more crushing and

The first step in iron ore processing is crushing, which aims to crush large pieces of iron ore to the required particle size for subsequent grinding and beneficiation. In view of the high hardness of iron ore, the principle of "more crushing and less grinding" should be followed, and a three-stage one-closed-circuit crushing mode should be adopted to efficiently complete the crushing operation.

Click here to consult iron ore equipment selection

1. Coarse crushing: jaw crusher or gyratory crusher

The large pieces of ore are first crushed to medium size by jaw crusher or gyratory crusher, laying the foundation for the subsequent medium and fine crushing. Jaw crusher is the first choice for coarse crushing of most ores due to its wide versatility; while gyratory crusher is more suitable for large metal mining projects, with high production capacity and an hourly output of more than 2,000 tons.

2. Medium crushing: standard cone crusher

The iron ore treated by jaw crusher is sent to standard cone crusher for further fine crushing. The single-cylinder hydraulic cone crusher is the preferred equipment. Its hydraulic system has better performance than the spring system, which can significantly improve the crushing efficiency and output, and simplify the subsequent maintenance work, which is more advantageous.

3. Fine crushing link: short-head cone crusher

The iron ore after medium crushing is sent to the short-head cone crusher for further fine crushing. The representative equipment can be selected as a multi-cylinder hydraulic cone crusher, which has different crushing chamber types such as coarse, medium, fine, and ultra-fine. The discharge range can reach 6-38mm, and the output fine material can be directly sent to the grinding equipment.

This is a classic configuration for iron ore crushing, and the equipment can be increased or decreased according to actual production needs. You can also choose a flexible mobile crushing station according to the production scale and working conditions of different projects.

Previous: SMP Crusher

Next: SMP Crusher

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore? How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced? How to improve the service life of impact sand making machine

How to improve the service life of impact sand making machine How to clean the inside of cone crusher

How to clean the inside of cone crusher What are the differences between coarse jaw crusher and fine jaw crusher?

What are the differences between coarse jaw crusher and fine jaw crusher? What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore? How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced? How to improve the service life of impact sand making machine

How to improve the service life of impact sand making machine How to clean the inside of cone crusher

How to clean the inside of cone crusher What are the differences between coarse jaw crusher and fine jaw crusher?

What are the differences between coarse jaw crusher and fine jaw crusher?