Choosing a suitable sand making machine requires considering many factors, including your production needs, raw material characteristics, budget, maintenance costs, and future expansion needs.How to choose sand making equipment Click

Choosing a suitable sand making machine requires considering many factors, including your production needs, raw material characteristics, budget, maintenance costs, and future expansion needs.

How to choose sand making equipment Click to consult

1. Production needs

If you want to make sand efficiently, the first step is to clarify the production needs, among which the hourly sand and gravel output is the key. The output data is directly related to the specifications and types of sand making machines. For example, if the output demand is large, it is necessary to match equipment with strong processing capacity and large specifications; if the output demand is small, a small sand making machine can meet it.

2. Raw material characteristics

When choosing a sand making machine, you must fully consider the characteristics of the raw materials to be processed. Factors such as hardness, humidity, and particle size are crucial. Different types of sand making machines have different adaptability to raw materials. For example, raw materials with too high hardness need to be matched with sand making machines with strong wear resistance to ensure that sand making operations are carried out efficiently and stably.

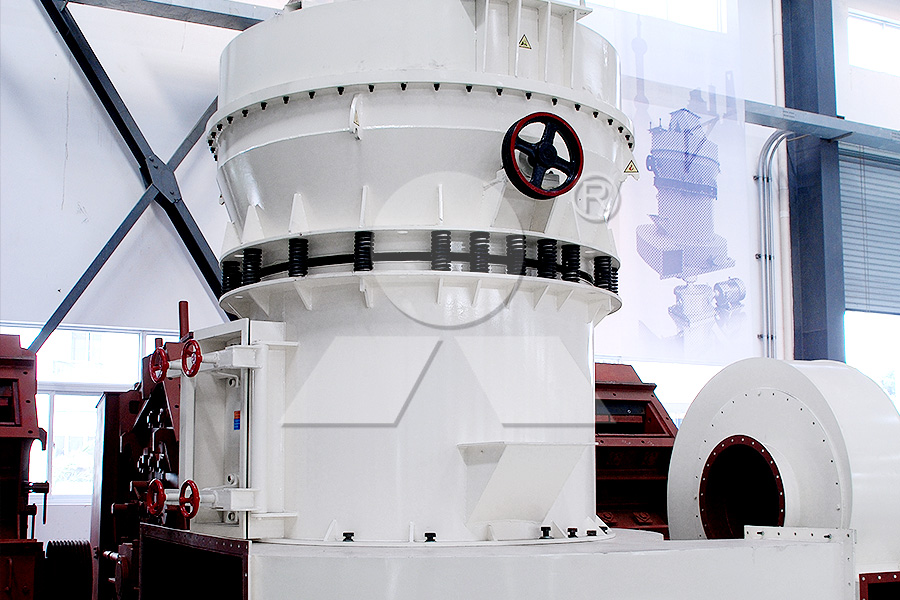

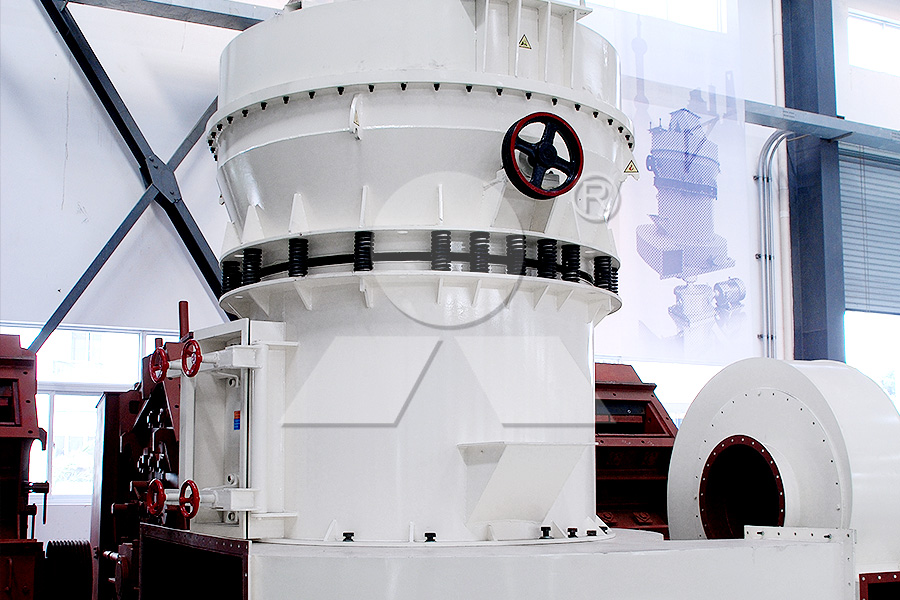

3. Sand making machine type

When selecting a sand making machine, you need to combine your own needs with the characteristics of the raw materials. If you are looking for high output and processing medium-hard materials, impact sand making machine is a good choice; for medium and fine crushing of hard materials, cone sand making machine is more suitable; and jaw sand making machine is good at coarse crushing of materials of various hardness, and you can make appropriate choices based on these characteristics.

4. Energy consumption

Pay attention to the energy consumption of the sand making machine, especially the energy consumption cost under long-term operation. Choosing a sand making machine with high energy efficiency can help you save a certain amount of energy costs.

5. Equipment quality

Choose a sand making machine with well-known brands and reliable quality, which can reduce the failure rate and extend the service life of the equipment.

6. Maintenance and service

Understand the maintenance requirements and warranty policy of the sand making machine, as well as the service support of the supplier. Make sure you can get repair and maintenance support in time to avoid production interruptions.

7. Cost budget

Choose a sand making machine with a high cost performance according to your budget constraints. You don’t have to choose the cheapest one, but consider the balance between performance and quality/price.

Previous: SMP Crusher

Next: SMP Crusher

Choosing a suitable sand making machine requires considering many factors, including your production needs, raw material characteristics, budget, maintenance costs, and future expansion needs.How to choose sand making equipment Click

Choosing a suitable sand making machine requires considering many factors, including your production needs, raw material characteristics, budget, maintenance costs, and future expansion needs.

How to choose sand making equipment Click to consult

1. Production needs

If you want to make sand efficiently, the first step is to clarify the production needs, among which the hourly sand and gravel output is the key. The output data is directly related to the specifications and types of sand making machines. For example, if the output demand is large, it is necessary to match equipment with strong processing capacity and large specifications; if the output demand is small, a small sand making machine can meet it.

2. Raw material characteristics

When choosing a sand making machine, you must fully consider the characteristics of the raw materials to be processed. Factors such as hardness, humidity, and particle size are crucial. Different types of sand making machines have different adaptability to raw materials. For example, raw materials with too high hardness need to be matched with sand making machines with strong wear resistance to ensure that sand making operations are carried out efficiently and stably.

3. Sand making machine type

When selecting a sand making machine, you need to combine your own needs with the characteristics of the raw materials. If you are looking for high output and processing medium-hard materials, impact sand making machine is a good choice; for medium and fine crushing of hard materials, cone sand making machine is more suitable; and jaw sand making machine is good at coarse crushing of materials of various hardness, and you can make appropriate choices based on these characteristics.

4. Energy consumption

Pay attention to the energy consumption of the sand making machine, especially the energy consumption cost under long-term operation. Choosing a sand making machine with high energy efficiency can help you save a certain amount of energy costs.

5. Equipment quality

Choose a sand making machine with well-known brands and reliable quality, which can reduce the failure rate and extend the service life of the equipment.

6. Maintenance and service

Understand the maintenance requirements and warranty policy of the sand making machine, as well as the service support of the supplier. Make sure you can get repair and maintenance support in time to avoid production interruptions.

7. Cost budget

Choose a sand making machine with a high cost performance according to your budget constraints. You don’t have to choose the cheapest one, but consider the balance between performance and quality/price.

Previous: SMP Crusher

Next: SMP Crusher

How to build a high-quality basalt sand making equipment production line

How to build a high-quality basalt sand making equipment production line What equipment is used to crush granite into sand

What equipment is used to crush granite into sand Which equipment to use for crushing iron ore

Which equipment to use for crushing iron ore What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore? How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced? How to build a high-quality basalt sand making equipment production line

How to build a high-quality basalt sand making equipment production line What equipment is used to crush granite into sand

What equipment is used to crush granite into sand Which equipment to use for crushing iron ore

Which equipment to use for crushing iron ore What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore? How is high-quality machine-made sand produced?

How is high-quality machine-made sand produced?