Tailings sand making is an emerging waste reuse method that reduces pollution, lowers costs, increases profits, and is in line with the circular economy. Shibang Group's VU system is leading and the equipment is reasonably configured to ensure effi

Tailings sand making is an emerging waste reuse method that reduces pollution, lowers costs, increases profits, and is in line with the circular economy. Shibang Group's VU system is leading and the equipment is reasonably configured to ensure efficient production. The tailings sand making market has broad prospects and huge room for future development, which will support green mining.

In the mining process, tailings are by-products of mineral processing operations and usually refer to those minerals containing the lowest useful components. Unable to be further sorted, tailings are often deposited as waste. However, with the expansion of mining scale, the amount of tailings is increasing year by year, which puts great pressure on the environment. How to deal with these tailings has become an urgent problem in the current mining industry.

Mining tailings sand making equipment consultation

Economic and environmental benefits of tailings sand production

In recent years, tailings sand production, as an emerging waste reuse method, has gradually attracted attention from all walks of life. Tailings can not only be used to produce high-quality manufactured sand, but also have significant advantages in environmental protection, resource recovery and economic benefits. First, tailings sand production reduces the occupation of land by tailings and its pollution to the environment. Secondly, the cost of tailings as a raw material is low, and companies can obtain higher profit returns through this method. Furthermore, using machine-made sand produced from tailings as construction aggregate can significantly reduce the amount of cement used in concrete production, saving about 14 yuan in cement costs per cubic meter of concrete.

At the same time, tailings sand production is also in line with the circular economy development concept advocated by the country, promoting the efficient use of resources and sustainable protection of the environment. In this way, tailings achieve the transformation of "waste into resources", which not only helps alleviate environmental problems, but also promotes the improvement of economic benefits of mining companies.

Shibang Group’s tailings sand making technology

In terms of tailings sand making technology, SBM Group’s VU aggregate optimization system is undoubtedly the leader in the industry. The system uses two key equipments, VU impact crusher and VU particle optimizing machine, which can effectively eliminate needle-like materials in tailings and optimize the shape and gradation of sand particles. VU impact crushing removes sharp edges and corners in sand grains through impact crushing, significantly improving the grain shape of the finished sand. The VU particle optimizing machine uses innovative low-energy crushing and shaping technology, and uses waterfall self-scrubbing technology to remove burrs and residual edges on the surface of the sand particles, optimizing the details of the sand particles, increasing the density and gradation of the sand, and greatly improving It improves the effect of transforming tailings into high-quality manufactured sand.

Tailings sand making equipment and production process

Tailings sand making requires a series of efficient equipment to realize raw material processing, sand making, screening and other processes. Generally speaking, tailings sand making projects need to be equipped with the following equipment:

Jaw crusher: used to break large pieces of tailings into medium-sized stones, with high output and powerful processing capacity.

Cone crusher: further crushes the stones into stones below 40mm, which is efficient and durable.

Sand making machine: Process stones into machine-made sand of different specifications. The finished product has good grain shape and is easy to control.

Sand washing machine: removes soil and impurities from machine-made sand to ensure the cleanliness of the finished sand.

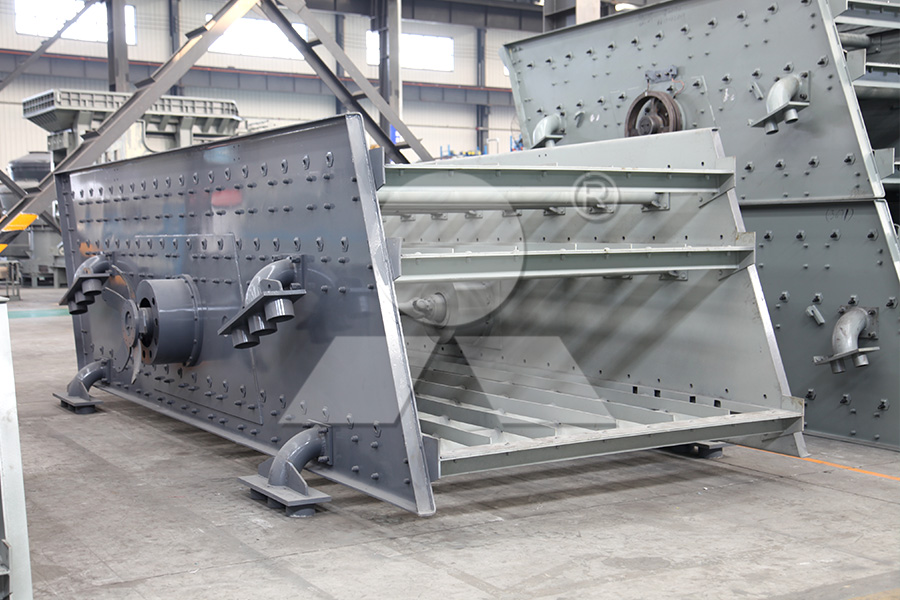

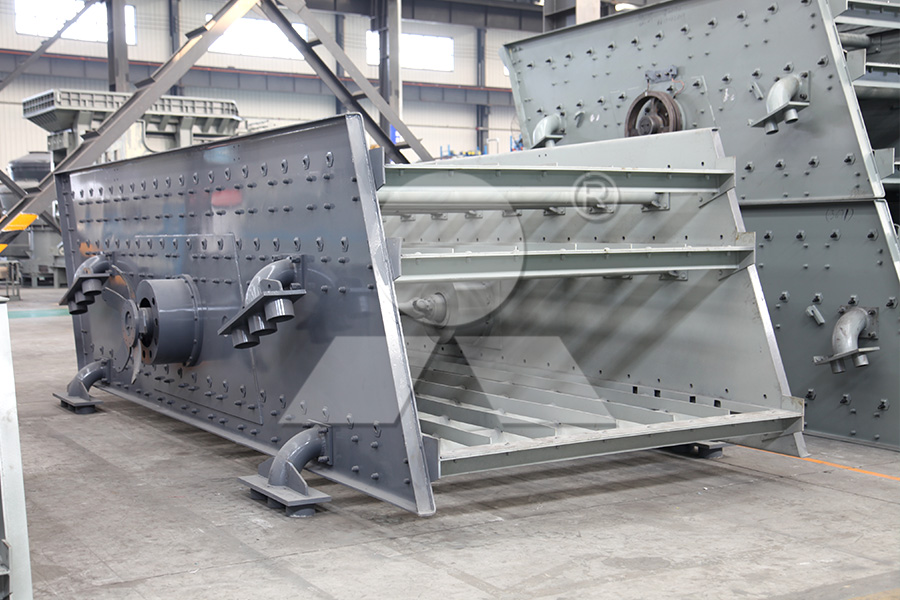

Auxiliary equipment: including feeders, vibrating screens, conveyors, etc., to ensure smooth transportation and screening of materials.

The reasonable configuration of this series of equipment ensures the efficient operation and stable production of the tailings sand making production line.

Market prospects of tailings sand making projects

According to statistics, the price of machine-made sand produced from tailings on the market is about 45 yuan per ton, which is equivalent to the price of machine-made sand made from construction waste, and has a very wide market. Especially in some areas rich in tailings resources, such as Henan, Shaanxi, Hebei and other places, tailings sand making projects have broad application prospects.

Shibang Group Case: Shaanxi 100 tons per hour tailings sand making demonstration line

Take the tailings sand making demonstration project in Shaanxi as an example. This project was jointly invested and constructed by Shibang Group and well-known local universities. The project scale is to produce 100 tons of high-quality manufactured sand per hour, which is mainly used in the construction of the Baolan-Lanzhou High-speed Railway Project. The core equipment of this project includes VSI5X1145 centrifugal impact crusher and 2Y2460 circular vibrating screen. Through advanced sand making technology, the efficient recovery and reuse of tailings is achieved.

In this project, the tailings are conveyed by a belt into the VSI5X1145 centrifugal impact crusher for preliminary crushing. After screening, 0-5mm manufactured sand is used as finished product for concrete production, and the remaining materials larger than 5mm are returned to the crusher for further processing. The entire production line is equipped with dust removal and powder selection equipment to ensure environmental protection requirements during the production process, reduce dust pollution, and promote green production.

The future of tailings sand production

With the continuous advancement of tailings treatment technology, tailings sand making can not only provide high-quality building materials, but also provide a new profit growth point for mining companies. Combined with the country's emphasis on environmental protection and resource recycling, the tailings sand making project will surely usher in a broader space for development. Investing in tailings sand making projects is not only in line with the concept of green development, but also a wise choice for enterprises to achieve efficient production, reduce costs, and enhance competitiveness.

Conclusion: The treatment of mine tailings is no longer a problem. Through modern tailings sand making technology, the waste can be converted into high-quality machine-made sand with economic value, creating more profit margins for mining companies, while promoting environmental protection and Sustainable development contributes to the construction of green mining and circular economy.

Previous: SMP Crusher

Next: SMP Crusher

Tailings sand making is an emerging waste reuse method that reduces pollution, lowers costs, increases profits, and is in line with the circular economy. Shibang Group's VU system is leading and the equipment is reasonably configured to ensure effi

Tailings sand making is an emerging waste reuse method that reduces pollution, lowers costs, increases profits, and is in line with the circular economy. Shibang Group's VU system is leading and the equipment is reasonably configured to ensure efficient production. The tailings sand making market has broad prospects and huge room for future development, which will support green mining.

In the mining process, tailings are by-products of mineral processing operations and usually refer to those minerals containing the lowest useful components. Unable to be further sorted, tailings are often deposited as waste. However, with the expansion of mining scale, the amount of tailings is increasing year by year, which puts great pressure on the environment. How to deal with these tailings has become an urgent problem in the current mining industry.

Mining tailings sand making equipment consultation

Economic and environmental benefits of tailings sand production

In recent years, tailings sand production, as an emerging waste reuse method, has gradually attracted attention from all walks of life. Tailings can not only be used to produce high-quality manufactured sand, but also have significant advantages in environmental protection, resource recovery and economic benefits. First, tailings sand production reduces the occupation of land by tailings and its pollution to the environment. Secondly, the cost of tailings as a raw material is low, and companies can obtain higher profit returns through this method. Furthermore, using machine-made sand produced from tailings as construction aggregate can significantly reduce the amount of cement used in concrete production, saving about 14 yuan in cement costs per cubic meter of concrete.

At the same time, tailings sand production is also in line with the circular economy development concept advocated by the country, promoting the efficient use of resources and sustainable protection of the environment. In this way, tailings achieve the transformation of "waste into resources", which not only helps alleviate environmental problems, but also promotes the improvement of economic benefits of mining companies.

Shibang Group’s tailings sand making technology

In terms of tailings sand making technology, SBM Group’s VU aggregate optimization system is undoubtedly the leader in the industry. The system uses two key equipments, VU impact crusher and VU particle optimizing machine, which can effectively eliminate needle-like materials in tailings and optimize the shape and gradation of sand particles. VU impact crushing removes sharp edges and corners in sand grains through impact crushing, significantly improving the grain shape of the finished sand. The VU particle optimizing machine uses innovative low-energy crushing and shaping technology, and uses waterfall self-scrubbing technology to remove burrs and residual edges on the surface of the sand particles, optimizing the details of the sand particles, increasing the density and gradation of the sand, and greatly improving It improves the effect of transforming tailings into high-quality manufactured sand.

Tailings sand making equipment and production process

Tailings sand making requires a series of efficient equipment to realize raw material processing, sand making, screening and other processes. Generally speaking, tailings sand making projects need to be equipped with the following equipment:

Jaw crusher: used to break large pieces of tailings into medium-sized stones, with high output and powerful processing capacity.

Cone crusher: further crushes the stones into stones below 40mm, which is efficient and durable.

Sand making machine: Process stones into machine-made sand of different specifications. The finished product has good grain shape and is easy to control.

Sand washing machine: removes soil and impurities from machine-made sand to ensure the cleanliness of the finished sand.

Auxiliary equipment: including feeders, vibrating screens, conveyors, etc., to ensure smooth transportation and screening of materials.

The reasonable configuration of this series of equipment ensures the efficient operation and stable production of the tailings sand making production line.

Market prospects of tailings sand making projects

According to statistics, the price of machine-made sand produced from tailings on the market is about 45 yuan per ton, which is equivalent to the price of machine-made sand made from construction waste, and has a very wide market. Especially in some areas rich in tailings resources, such as Henan, Shaanxi, Hebei and other places, tailings sand making projects have broad application prospects.

Shibang Group Case: Shaanxi 100 tons per hour tailings sand making demonstration line

Take the tailings sand making demonstration project in Shaanxi as an example. This project was jointly invested and constructed by Shibang Group and well-known local universities. The project scale is to produce 100 tons of high-quality manufactured sand per hour, which is mainly used in the construction of the Baolan-Lanzhou High-speed Railway Project. The core equipment of this project includes VSI5X1145 centrifugal impact crusher and 2Y2460 circular vibrating screen. Through advanced sand making technology, the efficient recovery and reuse of tailings is achieved.

In this project, the tailings are conveyed by a belt into the VSI5X1145 centrifugal impact crusher for preliminary crushing. After screening, 0-5mm manufactured sand is used as finished product for concrete production, and the remaining materials larger than 5mm are returned to the crusher for further processing. The entire production line is equipped with dust removal and powder selection equipment to ensure environmental protection requirements during the production process, reduce dust pollution, and promote green production.

The future of tailings sand production

With the continuous advancement of tailings treatment technology, tailings sand making can not only provide high-quality building materials, but also provide a new profit growth point for mining companies. Combined with the country's emphasis on environmental protection and resource recycling, the tailings sand making project will surely usher in a broader space for development. Investing in tailings sand making projects is not only in line with the concept of green development, but also a wise choice for enterprises to achieve efficient production, reduce costs, and enhance competitiveness.

Conclusion: The treatment of mine tailings is no longer a problem. Through modern tailings sand making technology, the waste can be converted into high-quality machine-made sand with economic value, creating more profit margins for mining companies, while promoting environmental protection and Sustainable development contributes to the construction of green mining and circular economy.

Previous: SMP Crusher

Next: SMP Crusher

Which crushing equipment is best for processing river pebbles into sand?

Which crushing equipment is best for processing river pebbles into sand? What is the price of a set of machine-made sand equipment?

What is the price of a set of machine-made sand equipment? How to build a high-yield sand production line

How to build a high-yield sand production line How much does a mobile crusher with an output of 100/150/300 tons per hour cost?

How much does a mobile crusher with an output of 100/150/300 tons per hour cost? Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste

Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste Which crushing equipment is best for processing river pebbles into sand?

Which crushing equipment is best for processing river pebbles into sand? What is the price of a set of machine-made sand equipment?

What is the price of a set of machine-made sand equipment? How to build a high-yield sand production line

How to build a high-yield sand production line How much does a mobile crusher with an output of 100/150/300 tons per hour cost?

How much does a mobile crusher with an output of 100/150/300 tons per hour cost? Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste

Waste concrete crushing line helps environmentally friendly and efficient resource recycling of construction solid waste