"A 400-ton sand and gravel production line needs to customize the equipment plan according to the characteristics of the stone. The fixed type has flexible configuration, low cost but complex installation; the mobile type is not restricted by the

"A 400-ton sand and gravel production line needs to customize the equipment plan according to the characteristics of the stone. The fixed type has flexible configuration, low cost but complex installation; the mobile type is not restricted by the site and can be moved at any time. Reasonable selection of crusher type and process flow is the key to improving efficiency."

Due to the differences in stone types, the hardness, humidity and other characteristics of the stone are different, so different equipment plans need to be configured. For a sand and gravel production line with an output of 400 tons per hour, its production scale is large, and the demand for crushers is more prominent, which requires reasonable planning to meet production requirements.

Click to consult to learn how to build a sand and gravel production line

Currently, there are two types of configurations for a 400-ton sand and gravel production line per hour: fixed and mobile. Customers can choose different configurations according to the type and purpose of gravel. Generally, manufacturers will adapt to local conditions, simplify the process flow, and reduce customers' investment costs.

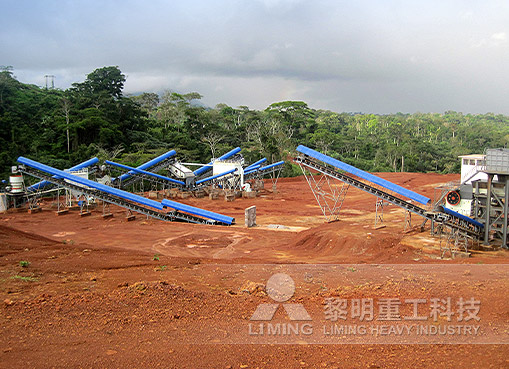

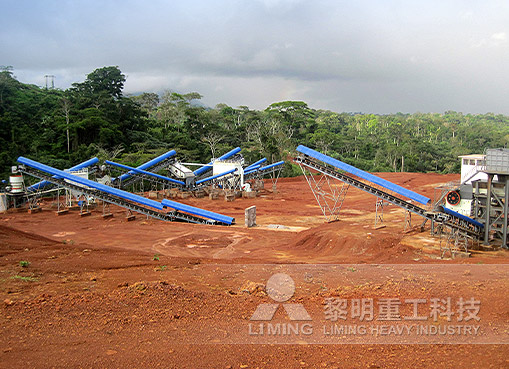

Fixed sand and gravel aggregate production line

Generally, fixed production lines tend to be located in flat and large material yards. It has many advantages, such as high flexibility in equipment configuration, strong processing capacity, and relatively low investment costs. However, its installation process is relatively complicated, and piling operations are required during the installation process, and corresponding auxiliary equipment is also required.

Workflow

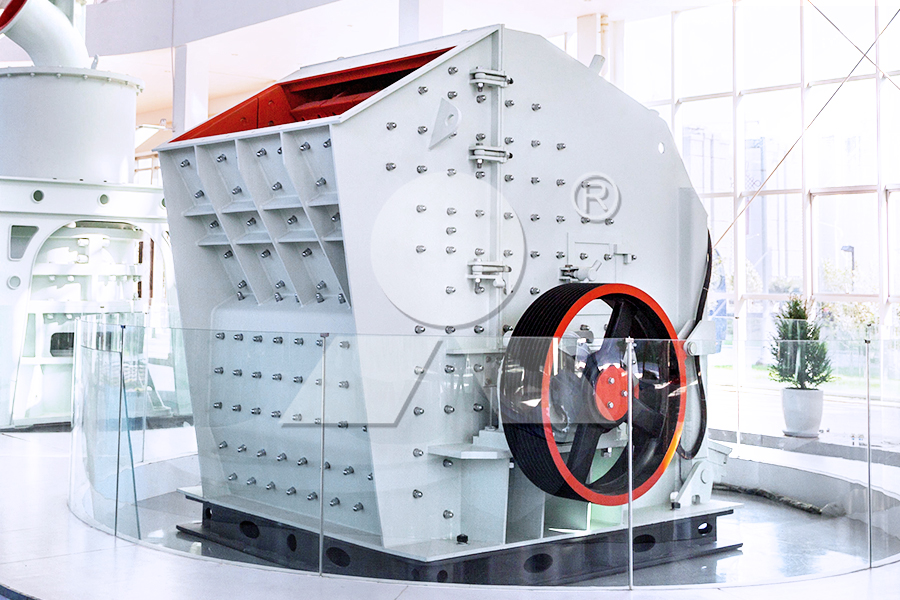

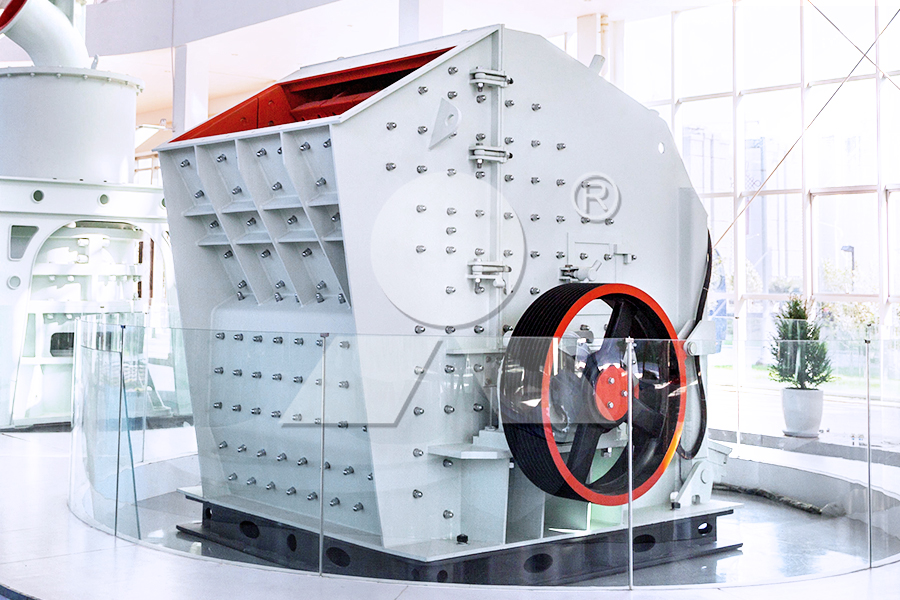

In the sand and gravel production process, first, the stone is evenly and stably fed into the crusher for coarse crushing by a vibrating feeder. The coarsely crushed stone is transported to the fine crusher through a conveyor belt. After screening, qualified finished products will be sent to the finished product storage yard; unqualified stones will be returned to the fine crusher through another conveyor belt for re-crushing. According to the hardness difference of the stone, the impact crusher or cone crusher can be flexibly selected to undertake the fine crushing task.

Mobile sand and gravel aggregate production line

The mobile production line is relatively simple to operate. All equipment is installed on mobile equipment, and the stone can be processed anywhere. After processing, it can be driven away at any time without being restricted by the site. It can be its own production line or a joint production of multiple machines.

Previous: SMP Crusher

Next: SMP Crusher

"A 400-ton sand and gravel production line needs to customize the equipment plan according to the characteristics of the stone. The fixed type has flexible configuration, low cost but complex installation; the mobile type is not restricted by the

"A 400-ton sand and gravel production line needs to customize the equipment plan according to the characteristics of the stone. The fixed type has flexible configuration, low cost but complex installation; the mobile type is not restricted by the site and can be moved at any time. Reasonable selection of crusher type and process flow is the key to improving efficiency."

Due to the differences in stone types, the hardness, humidity and other characteristics of the stone are different, so different equipment plans need to be configured. For a sand and gravel production line with an output of 400 tons per hour, its production scale is large, and the demand for crushers is more prominent, which requires reasonable planning to meet production requirements.

Click to consult to learn how to build a sand and gravel production line

Currently, there are two types of configurations for a 400-ton sand and gravel production line per hour: fixed and mobile. Customers can choose different configurations according to the type and purpose of gravel. Generally, manufacturers will adapt to local conditions, simplify the process flow, and reduce customers' investment costs.

Fixed sand and gravel aggregate production line

Generally, fixed production lines tend to be located in flat and large material yards. It has many advantages, such as high flexibility in equipment configuration, strong processing capacity, and relatively low investment costs. However, its installation process is relatively complicated, and piling operations are required during the installation process, and corresponding auxiliary equipment is also required.

Workflow

In the sand and gravel production process, first, the stone is evenly and stably fed into the crusher for coarse crushing by a vibrating feeder. The coarsely crushed stone is transported to the fine crusher through a conveyor belt. After screening, qualified finished products will be sent to the finished product storage yard; unqualified stones will be returned to the fine crusher through another conveyor belt for re-crushing. According to the hardness difference of the stone, the impact crusher or cone crusher can be flexibly selected to undertake the fine crushing task.

Mobile sand and gravel aggregate production line

The mobile production line is relatively simple to operate. All equipment is installed on mobile equipment, and the stone can be processed anywhere. After processing, it can be driven away at any time without being restricted by the site. It can be its own production line or a joint production of multiple machines.

Previous: SMP Crusher

Next: SMP Crusher

How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design