Hunan has built a 500-ton wet sand production line, which uses two-stage crushing + fine sand making technology to produce 0-5mm high-speed rail grade machine-made sand. The hydraulic automation equipment is energy-saving and environmentally friendly,

Hunan has built a 500-ton wet sand production line, which uses two-stage crushing + fine sand making technology to produce 0-5mm high-speed rail grade machine-made sand. The hydraulic automation equipment is energy-saving and environmentally friendly, providing high-quality aggregates for major projects.

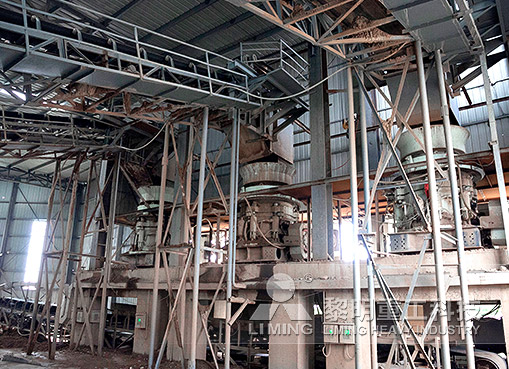

In order to solve the problem of high-quality sand and gravel supply, Hunan has built a 500-ton river pebble/limestone crushing and sand production line. In terms of production technology, the project adopts advanced wet processing technology and is equipped with a two-stage crushing + fine sand making process. This process setting can handle raw materials such as river pebbles and limestone with medium hardness or below. Through multi-stage crushing and fine shaping, it can produce 0-5mm high-quality machine-made sand that meets the requirements of major projects such as high-speed rail and highways. The project is designed to have a processing capacity of up to 500 tons per hour, which fully meets the sand needs of the company's own mixing station and surrounding key projects.

Click here to consult about the stone production line construction plan

In terms of equipment configuration, the entire production line adopts the automated crushing and screening system provided by Shibang: F5X series vibrating feeder realizes uniform feeding; C6X jaw crusher completes coarse crushing; HST single-cylinder hydraulic cone crusher and HPT multi-cylinder hydraulic cone crusher constitute the secondary medium crushing link; VSI6X vertical shaft impact crusher constitutes the core of sand making process; S5X series vibrating screen realizes efficient screening. The whole set of equipment adopts hydraulic control technology, which is easy to operate and runs smoothly.

In terms of technical advantages, the project has the following characteristics:

1. The process equipment is advanced and reliable, and the core equipment with independent intellectual property rights is adopted. The production process and equipment configuration are in line with the current advanced level of the industry;

2. The design plan fully combines the site conditions and uses the original terrain drop to achieve energy saving and consumption reduction, while ensuring the processing capacity and reducing the equipment investment and operating costs;

3. Green environmental protection meets the standards, the wet process effectively controls dust pollution, and is equipped with a complete wastewater treatment system to achieve clean production.

The successful commissioning of this project not only meets the company's own raw material needs for concrete production, but also provides high-quality sand and gravel aggregate support for local key projects, achieving a win-win situation in terms of economic and social benefits. The production process and equipment configuration scheme adopted by it have important reference value for similar sand and gravel processing projects, and provide useful experience for promoting technological progress and green development in the industry.

With the improvement of the level of building industrialization and increasingly stringent environmental protection requirements, this high-standard, high-efficiency, low-energy consumption modern sand and gravel production line will become an important direction for the development of the industry. In the future, by continuously optimizing process parameters and equipment performance, sand and gravel aggregate production will develop in a smarter and more environmentally friendly direction.

Previous: SMP Crusher

Next: SMP Crusher

Hunan has built a 500-ton wet sand production line, which uses two-stage crushing + fine sand making technology to produce 0-5mm high-speed rail grade machine-made sand. The hydraulic automation equipment is energy-saving and environmentally friendly,

Hunan has built a 500-ton wet sand production line, which uses two-stage crushing + fine sand making technology to produce 0-5mm high-speed rail grade machine-made sand. The hydraulic automation equipment is energy-saving and environmentally friendly, providing high-quality aggregates for major projects.

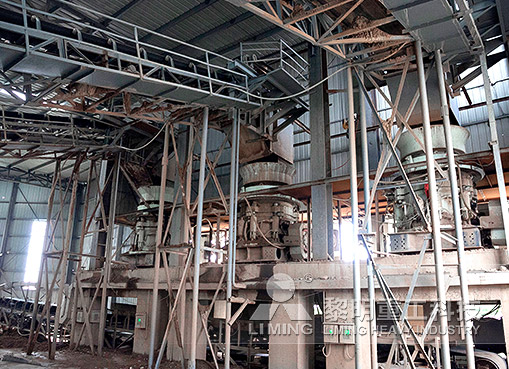

In order to solve the problem of high-quality sand and gravel supply, Hunan has built a 500-ton river pebble/limestone crushing and sand production line. In terms of production technology, the project adopts advanced wet processing technology and is equipped with a two-stage crushing + fine sand making process. This process setting can handle raw materials such as river pebbles and limestone with medium hardness or below. Through multi-stage crushing and fine shaping, it can produce 0-5mm high-quality machine-made sand that meets the requirements of major projects such as high-speed rail and highways. The project is designed to have a processing capacity of up to 500 tons per hour, which fully meets the sand needs of the company's own mixing station and surrounding key projects.

Click here to consult about the stone production line construction plan

In terms of equipment configuration, the entire production line adopts the automated crushing and screening system provided by Shibang: F5X series vibrating feeder realizes uniform feeding; C6X jaw crusher completes coarse crushing; HST single-cylinder hydraulic cone crusher and HPT multi-cylinder hydraulic cone crusher constitute the secondary medium crushing link; VSI6X vertical shaft impact crusher constitutes the core of sand making process; S5X series vibrating screen realizes efficient screening. The whole set of equipment adopts hydraulic control technology, which is easy to operate and runs smoothly.

In terms of technical advantages, the project has the following characteristics:

1. The process equipment is advanced and reliable, and the core equipment with independent intellectual property rights is adopted. The production process and equipment configuration are in line with the current advanced level of the industry;

2. The design plan fully combines the site conditions and uses the original terrain drop to achieve energy saving and consumption reduction, while ensuring the processing capacity and reducing the equipment investment and operating costs;

3. Green environmental protection meets the standards, the wet process effectively controls dust pollution, and is equipped with a complete wastewater treatment system to achieve clean production.

The successful commissioning of this project not only meets the company's own raw material needs for concrete production, but also provides high-quality sand and gravel aggregate support for local key projects, achieving a win-win situation in terms of economic and social benefits. The production process and equipment configuration scheme adopted by it have important reference value for similar sand and gravel processing projects, and provide useful experience for promoting technological progress and green development in the industry.

With the improvement of the level of building industrialization and increasingly stringent environmental protection requirements, this high-standard, high-efficiency, low-energy consumption modern sand and gravel production line will become an important direction for the development of the industry. In the future, by continuously optimizing process parameters and equipment performance, sand and gravel aggregate production will develop in a smarter and more environmentally friendly direction.

Previous: SMP Crusher

Next: SMP Crusher

Sichuan 400-ton limestone crushing production line a model of high efficiency and environmental protection

Sichuan 400-ton limestone crushing production line a model of high efficiency and environmental protection Ore crusher manufacturers analyze the production process of machine-made sand

Ore crusher manufacturers analyze the production process of machine-made sand Technical advantages and equipment selection of 800 tons per hour large limestone processing production line

Technical advantages and equipment selection of 800 tons per hour large limestone processing production line How to buy sand making and crushing equipment with high comprehensive cost performance

How to buy sand making and crushing equipment with high comprehensive cost performance What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output

What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output Sichuan 400-ton limestone crushing production line a model of high efficiency and environmental protection

Sichuan 400-ton limestone crushing production line a model of high efficiency and environmental protection Ore crusher manufacturers analyze the production process of machine-made sand

Ore crusher manufacturers analyze the production process of machine-made sand Technical advantages and equipment selection of 800 tons per hour large limestone processing production line

Technical advantages and equipment selection of 800 tons per hour large limestone processing production line How to buy sand making and crushing equipment with high comprehensive cost performance

How to buy sand making and crushing equipment with high comprehensive cost performance What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output

What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output