Sichuan's 300-400 tons per hour limestone crushing production line uses Shibang Industrial Technology Group's equipment. With scientific process and efficient equipment configuration, it realizes fine material classification and environmentally

Sichuan's 300-400 tons per hour limestone crushing production line uses Shibang Industrial Technology Group's equipment. With scientific process and efficient equipment configuration, it realizes fine material classification and environmentally friendly production, and provides customers with stable and high-yield high-quality sand and gravel solutions.

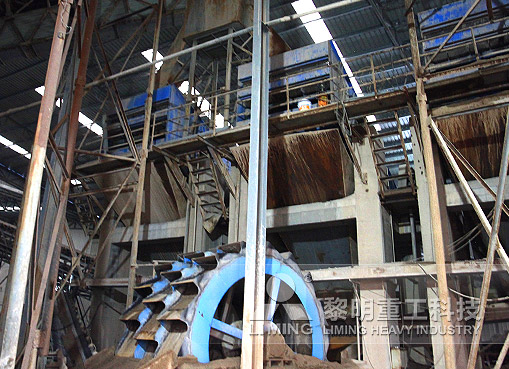

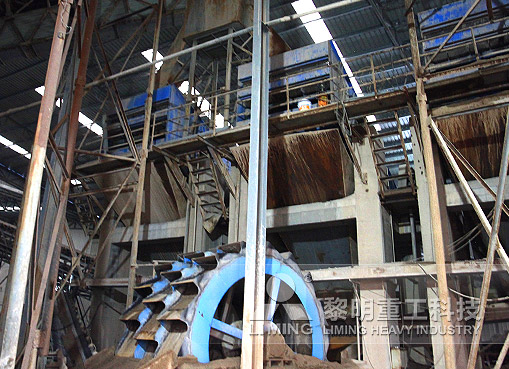

A 300-400 tons per hour limestone crushing production line that is about to be put into production in Sichuan has attracted much attention. After in-depth investigation and repeated comparison of equipment from multiple manufacturers, the customer of this production line finally firmly chose the crushing equipment of Shibang Industrial Technology Group. This choice is not only due to the trust in the brand of Shibang Industrial Technology Group, but also a high recognition of its equipment performance and production plan.

Click to consult to understand the construction plan of the sand and gravel production line

From the process flow, this production line shows a high degree of scientificity and rationality. The raw materials after the mountain blasting are transported to the raw material warehouse by car, and then the F5X1345 vibrating feeder plays a key role. It can evenly and stably feed the materials into the PEW860 for crushing. The feeder can also pre-screen the materials during the feeding process, effectively remove the soil, and provide better quality raw materials for the subsequent crushing process.

After the material enters the primary crushing equipment PFW860 European hydraulic jaw crusher, it is crushed to less than 25 cm. After meeting the discharge requirements, it is conveyed to two PFW1315Ⅲ impact crushers through a belt conveyor for further crushing. After that, the material is screened by the S5X2760-2 vibrating screen, and the materials of different particle sizes are reasonably distributed: 0-5mm is transported to the finished product pile as finished stone powder; those above 26.5mm return to the impact crusher for further crushing; 5-26.5mm enters the transfer silo.

The material in the transfer silo is transported to the VSI5X1145 shaping machine for shaping. The shaped material is then screened by the S5X2460-3 vibrating screen into four finished materials of 0-5, 5-9.5, 9.5-16.5, and 16.5-26.5mm, and transported to the finished product pile. The entire process is closely linked to ensure efficient material processing and stable quality of finished products.

In terms of equipment configuration, this production line has significant advantages. Shibang participated in the design throughout the process, and conducted multiple demonstrations and optimizations on equipment selection and process flow. This rigorous attitude and professional technology not only reduced unnecessary investment for customers, but also ensured the output and smooth operation of the production line. Advanced production equipment is the guarantee of high quality of finished products, and high-quality equipment further ensures the stable operation of the production line. For example, the PEW jaw crusher has strong crushing capacity and reliable operating performance, and can efficiently complete the initial crushing task; the PFW impact crusher provides a good foundation for subsequent screening and shaping with its excellent crushing effect and particle shape adjustment ability; the VSI vertical shaft impact crusher, as a shaping machine, can significantly improve the particle shape of the material and improve the quality of the finished product.

The production line also meets high standards in environmental protection design. In today's society, environmental protection has become an important consideration for the development of enterprises. By adopting advanced environmental protection technologies and equipment, this production line has greatly reduced the impact on the surrounding environment and achieved a win-win situation of economic and social benefits.

Previous: SMP Crusher

Next: SMP Crusher

Sichuan's 300-400 tons per hour limestone crushing production line uses Shibang Industrial Technology Group's equipment. With scientific process and efficient equipment configuration, it realizes fine material classification and environmentally

Sichuan's 300-400 tons per hour limestone crushing production line uses Shibang Industrial Technology Group's equipment. With scientific process and efficient equipment configuration, it realizes fine material classification and environmentally friendly production, and provides customers with stable and high-yield high-quality sand and gravel solutions.

A 300-400 tons per hour limestone crushing production line that is about to be put into production in Sichuan has attracted much attention. After in-depth investigation and repeated comparison of equipment from multiple manufacturers, the customer of this production line finally firmly chose the crushing equipment of Shibang Industrial Technology Group. This choice is not only due to the trust in the brand of Shibang Industrial Technology Group, but also a high recognition of its equipment performance and production plan.

Click to consult to understand the construction plan of the sand and gravel production line

From the process flow, this production line shows a high degree of scientificity and rationality. The raw materials after the mountain blasting are transported to the raw material warehouse by car, and then the F5X1345 vibrating feeder plays a key role. It can evenly and stably feed the materials into the PEW860 for crushing. The feeder can also pre-screen the materials during the feeding process, effectively remove the soil, and provide better quality raw materials for the subsequent crushing process.

After the material enters the primary crushing equipment PFW860 European hydraulic jaw crusher, it is crushed to less than 25 cm. After meeting the discharge requirements, it is conveyed to two PFW1315Ⅲ impact crushers through a belt conveyor for further crushing. After that, the material is screened by the S5X2760-2 vibrating screen, and the materials of different particle sizes are reasonably distributed: 0-5mm is transported to the finished product pile as finished stone powder; those above 26.5mm return to the impact crusher for further crushing; 5-26.5mm enters the transfer silo.

The material in the transfer silo is transported to the VSI5X1145 shaping machine for shaping. The shaped material is then screened by the S5X2460-3 vibrating screen into four finished materials of 0-5, 5-9.5, 9.5-16.5, and 16.5-26.5mm, and transported to the finished product pile. The entire process is closely linked to ensure efficient material processing and stable quality of finished products.

In terms of equipment configuration, this production line has significant advantages. Shibang participated in the design throughout the process, and conducted multiple demonstrations and optimizations on equipment selection and process flow. This rigorous attitude and professional technology not only reduced unnecessary investment for customers, but also ensured the output and smooth operation of the production line. Advanced production equipment is the guarantee of high quality of finished products, and high-quality equipment further ensures the stable operation of the production line. For example, the PEW jaw crusher has strong crushing capacity and reliable operating performance, and can efficiently complete the initial crushing task; the PFW impact crusher provides a good foundation for subsequent screening and shaping with its excellent crushing effect and particle shape adjustment ability; the VSI vertical shaft impact crusher, as a shaping machine, can significantly improve the particle shape of the material and improve the quality of the finished product.

The production line also meets high standards in environmental protection design. In today's society, environmental protection has become an important consideration for the development of enterprises. By adopting advanced environmental protection technologies and equipment, this production line has greatly reduced the impact on the surrounding environment and achieved a win-win situation of economic and social benefits.

Previous: SMP Crusher

Next: SMP Crusher

Ore crusher manufacturers analyze the production process of machine-made sand

Ore crusher manufacturers analyze the production process of machine-made sand Technical advantages and equipment selection of 800 tons per hour large limestone processing production line

Technical advantages and equipment selection of 800 tons per hour large limestone processing production line How to buy sand making and crushing equipment with high comprehensive cost performance

How to buy sand making and crushing equipment with high comprehensive cost performance What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output

What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output What equipment does the basalt crushing and shaping production line have?

What equipment does the basalt crushing and shaping production line have? Ore crusher manufacturers analyze the production process of machine-made sand

Ore crusher manufacturers analyze the production process of machine-made sand Technical advantages and equipment selection of 800 tons per hour large limestone processing production line

Technical advantages and equipment selection of 800 tons per hour large limestone processing production line How to buy sand making and crushing equipment with high comprehensive cost performance

How to buy sand making and crushing equipment with high comprehensive cost performance What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output

What are the reasons why the output of granite sand making equipment does not meet the standard? How to increase the output What equipment does the basalt crushing and shaping production line have?

What equipment does the basalt crushing and shaping production line have?