The customer's manganese ore production place is mainly dominated by rhodochrosite and calcium rhodochrosite, followed by manganese calcite, Liming Heavy Industry's technical design team, after research, suggests the user to adopt the strong ma

The customer's manganese ore production place is mainly dominated by rhodochrosite and calcium rhodochrosite, followed by manganese calcite, Liming Heavy Industry's technical design team, after research, suggests the user to adopt the strong magnetic separation process, which can make the manganese ore achieve better sorting under the condition of higher magnetic field strength, and realise the balance of yield and grade, and bring the user a high income.

Manganese ore beneficiation production line production

Henan Liming Heavy Industry technicians designed the production line after investigating its actual beneficiation conditions, and its main production process is as follows:

1、Crushing: For the big raw manganese ore, it needs to be simply crushed first to make its particle size smaller, and then crushed again for processing;

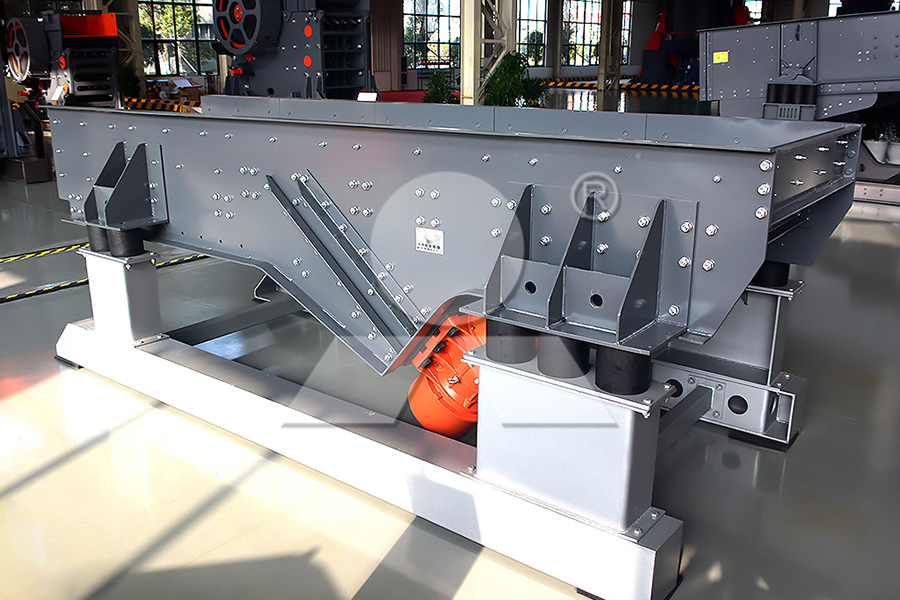

2、Grinding: then grinding, after crushing process, the manganese ore is crushed through the vibrating screen using ball mill and spiral classifier to grind and classify it, which is convenient for the next magnetic separation process;

3、Screening: the bottom stream of classifier is sent to the magnetic separator for selection, and the overflow of classification is concentrated by thickener; finally, the overflow of concentration is used as the water return system, and the bottom stream of concentration is converged with the concentrate, which becomes the final selection concentrate.

4、Magnetic separation: firstly, the material is fed by vibrating feeder, and then the impurities in manganese ore are removed by manganese ore magnetic separator initially, the roughing concentrate is graded by spiral classifier, and the roughing tailings are directly discharged to tailings thickener.

Customer Feedback: We have to praise Liming Heavy Industry to our design of manganese ore beneficiation production line, the use of strong magnetic separation process, smooth flow, step by step reasonable, magnetic separation effect is very good, the quality of the equipment is also good, not only the design of the production line is in line with our reality, and the purchase of a full set of equipment is also quite cost-effective, put into operation than the expected economic benefits to be much higher than the equipment can only say that the equipment is very worthwhile to buy, the manufacturer is also the right choice.

Previous: SMP Crusher

Next: SMP Crusher

The customer's manganese ore production place is mainly dominated by rhodochrosite and calcium rhodochrosite, followed by manganese calcite, Liming Heavy Industry's technical design team, after research, suggests the user to adopt the strong ma

The customer's manganese ore production place is mainly dominated by rhodochrosite and calcium rhodochrosite, followed by manganese calcite, Liming Heavy Industry's technical design team, after research, suggests the user to adopt the strong magnetic separation process, which can make the manganese ore achieve better sorting under the condition of higher magnetic field strength, and realise the balance of yield and grade, and bring the user a high income.

Manganese ore beneficiation production line production

Henan Liming Heavy Industry technicians designed the production line after investigating its actual beneficiation conditions, and its main production process is as follows:

1、Crushing: For the big raw manganese ore, it needs to be simply crushed first to make its particle size smaller, and then crushed again for processing;

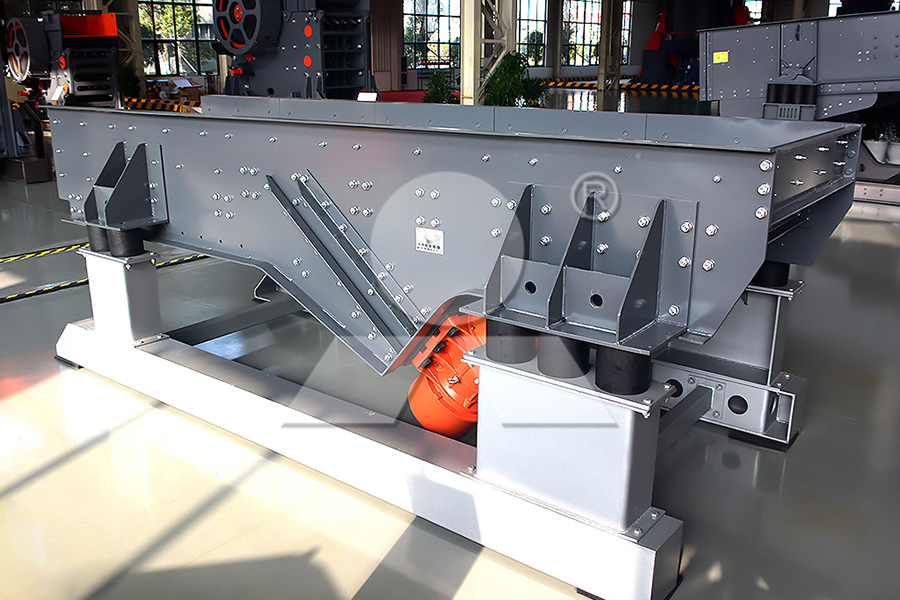

2、Grinding: then grinding, after crushing process, the manganese ore is crushed through the vibrating screen using ball mill and spiral classifier to grind and classify it, which is convenient for the next magnetic separation process;

3、Screening: the bottom stream of classifier is sent to the magnetic separator for selection, and the overflow of classification is concentrated by thickener; finally, the overflow of concentration is used as the water return system, and the bottom stream of concentration is converged with the concentrate, which becomes the final selection concentrate.

4、Magnetic separation: firstly, the material is fed by vibrating feeder, and then the impurities in manganese ore are removed by manganese ore magnetic separator initially, the roughing concentrate is graded by spiral classifier, and the roughing tailings are directly discharged to tailings thickener.

Customer Feedback: We have to praise Liming Heavy Industry to our design of manganese ore beneficiation production line, the use of strong magnetic separation process, smooth flow, step by step reasonable, magnetic separation effect is very good, the quality of the equipment is also good, not only the design of the production line is in line with our reality, and the purchase of a full set of equipment is also quite cost-effective, put into operation than the expected economic benefits to be much higher than the equipment can only say that the equipment is very worthwhile to buy, the manufacturer is also the right choice.

Previous: SMP Crusher

Next: SMP Crusher

Guangxi manganese ore magnetic separation process production line

Guangxi manganese ore magnetic separation process production line Liaoning Anshan large scale iron ore magnetic separation process production line

Liaoning Anshan large scale iron ore magnetic separation process production line Yunnan copper ore flotation process production line

Yunnan copper ore flotation process production line Liaoning talc flotation process production line

Liaoning talc flotation process production line Sichuan phosphorus ore flotation process production line

Sichuan phosphorus ore flotation process production line Guangxi manganese ore magnetic separation process production line

Guangxi manganese ore magnetic separation process production line Liaoning Anshan large scale iron ore magnetic separation process production line

Liaoning Anshan large scale iron ore magnetic separation process production line Yunnan copper ore flotation process production line

Yunnan copper ore flotation process production line Liaoning talc flotation process production line

Liaoning talc flotation process production line Sichuan phosphorus ore flotation process production line

Sichuan phosphorus ore flotation process production line