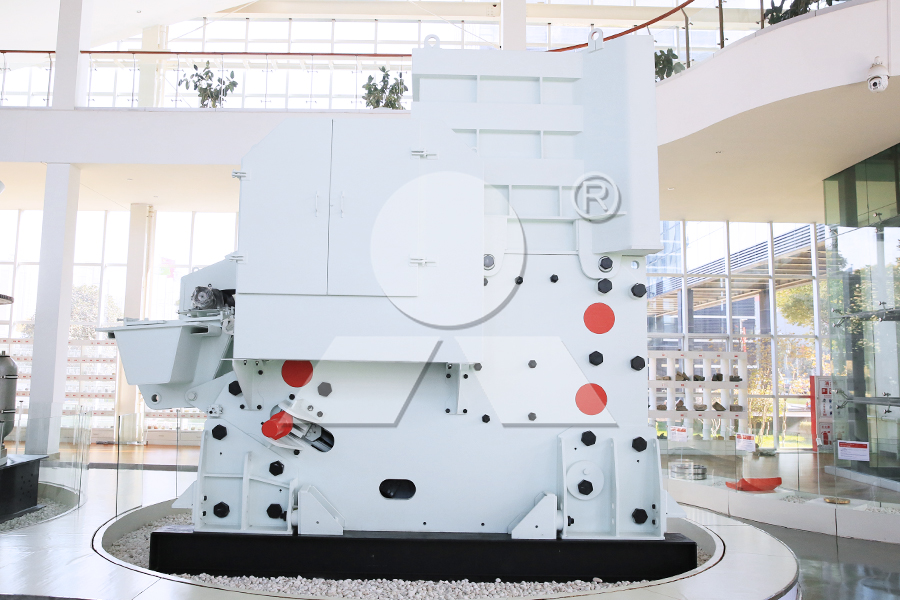

Among large-scale stone crushing equipment, the cone crusher is a widely used equipment. The factors that cause the cone crusher's processing capacity to decline mainly include the following aspects:To learn more about stone equi

Among large-scale stone crushing equipment, the cone crusher is a widely used equipment. The factors that cause the cone crusher's processing capacity to decline mainly include the following aspects:

To learn more about stone equipment prices, click to consult

1. Equipment quality

High-quality cone crushers perform stably in production and have low failure rates. This means that it can work continuously with minimal disruption to the production process, thus ensuring efficient material handling capabilities. Poor quality cone crushers are prone to failure and require frequent shutdowns for repairs. The quality of the cone crusher directly determines its production capacity. High-quality equipment can bring higher processing efficiency and better production benefits, while inferior equipment will drag down the overall production progress.

2. Nature of materials

The processing capacity of the cone crusher is significantly affected by the properties of the processed materials. Materials of different properties have different processing difficulties, which leads to changes in the processing capacity. For example, when the moisture content of the materials is high, these materials are likely to stick together and form clumps in the crushing cavity, causing clogging problems. In order to remove the blockage and restore the equipment's normal processing capabilities, the operator had to pause the machine for cleaning. This cleaning process will undoubtedly interrupt the continuous operation of the cone crusher, thereby reducing its overall processing capacity.

3. Maintenance work

Because when the cone crusher is working, there will be wear of parts. This wear phenomenon will cause the performance of the equipment to decrease, so maintenance work is required to extend the service life of the equipment and reduce the impact on performance. When maintaining When the work is unreasonable and parts wear out, the performance of the equipment will decrease and the number of materials processed per unit time will decrease.

Previous: SMP Crusher

Next: SMP Crusher

Among large-scale stone crushing equipment, the cone crusher is a widely used equipment. The factors that cause the cone crusher's processing capacity to decline mainly include the following aspects:To learn more about stone equi

Among large-scale stone crushing equipment, the cone crusher is a widely used equipment. The factors that cause the cone crusher's processing capacity to decline mainly include the following aspects:

To learn more about stone equipment prices, click to consult

1. Equipment quality

High-quality cone crushers perform stably in production and have low failure rates. This means that it can work continuously with minimal disruption to the production process, thus ensuring efficient material handling capabilities. Poor quality cone crushers are prone to failure and require frequent shutdowns for repairs. The quality of the cone crusher directly determines its production capacity. High-quality equipment can bring higher processing efficiency and better production benefits, while inferior equipment will drag down the overall production progress.

2. Nature of materials

The processing capacity of the cone crusher is significantly affected by the properties of the processed materials. Materials of different properties have different processing difficulties, which leads to changes in the processing capacity. For example, when the moisture content of the materials is high, these materials are likely to stick together and form clumps in the crushing cavity, causing clogging problems. In order to remove the blockage and restore the equipment's normal processing capabilities, the operator had to pause the machine for cleaning. This cleaning process will undoubtedly interrupt the continuous operation of the cone crusher, thereby reducing its overall processing capacity.

3. Maintenance work

Because when the cone crusher is working, there will be wear of parts. This wear phenomenon will cause the performance of the equipment to decrease, so maintenance work is required to extend the service life of the equipment and reduce the impact on performance. When maintaining When the work is unreasonable and parts wear out, the performance of the equipment will decrease and the number of materials processed per unit time will decrease.

Previous: SMP Crusher

Next: SMP Crusher

What are the advantages of large-scale jaw crusher for crushing pebbles? How to choose equipment

What are the advantages of large-scale jaw crusher for crushing pebbles? How to choose equipment 300 tons per hour sand and gravel production line configuration plan

300 tons per hour sand and gravel production line configuration plan How to choose brick slag crushing equipment

How to choose brick slag crushing equipment 600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production What are the advantages of large-scale jaw crusher for crushing pebbles? How to choose equipment

What are the advantages of large-scale jaw crusher for crushing pebbles? How to choose equipment 300 tons per hour sand and gravel production line configuration plan

300 tons per hour sand and gravel production line configuration plan How to choose brick slag crushing equipment

How to choose brick slag crushing equipment 600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production