The 1.2 million tons/year limestone crushing and sand making project designed by Liming for a customer has successfully created a high-yield, high-efficiency, energy-saving and environmentally friendly benchmark production line with advanced equipment

The 1.2 million tons/year limestone crushing and sand making project designed by Liming for a customer has successfully created a high-yield, high-efficiency, energy-saving and environmentally friendly benchmark production line with advanced equipment configuration, intelligent production methods and green environmental protection concepts.

1. Project Overview and High-standard Capacity Design

The project uses limestone as raw material, with a designed annual production capacity of 1.2 million tons, and operates 20 hours a day. The finished products include 0-3mm fine machine-made sand, 3-8mm melon seed slices and 8-31.5mm gravel, all of which are supplied to the mixing station. All three types of finished products have the characteristics of uniform particle shape and high compressive strength. Among them, the roundness and gradation of the machine-made sand are comparable to natural river sand, which has been highly recognized by the terminal market.

To ensure production capacity and quality, a combination of high-performance equipment from Liming was selected:

CI5X impact crusher is the core of coarse crushing, which has both high crushing ratio and low energy consumption characteristics;

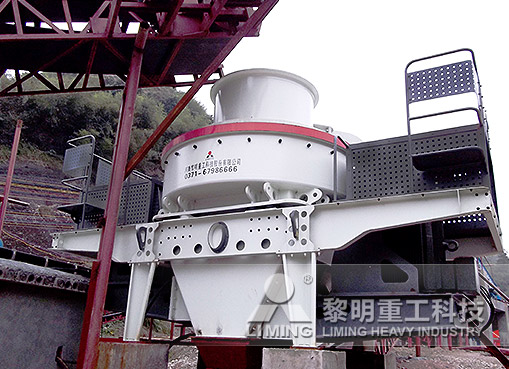

VSI6X sand making machine is responsible for shaping sand making, optimizing the finished product particle shape through the dual modes of "stone hitting stone" and "stone hitting iron";

S5X vibrating screen realizes multi-level precise grading to ensure high screening efficiency of three specifications of aggregates.

2. Deep integration of intelligent and environmental protection technologies

1. Intelligent integrated control system

The production line adopts a central control design, and operators can monitor the equipment operation status, adjust parameters, and receive fault warnings in real time through the control room. For example, the rotor speed of the impact crusher, the feed volume of the sand making machine and other data can be remotely controlled, greatly reducing the need for manual intervention and improving production efficiency.

2. Green production full process coverage

The project adopts dry process to avoid sewage discharge problems from the source, and realizes dust through four major environmental protection measures:

Semi-sealed plant design: Crushing, screening and other major processes are carried out in a closed environment;

Dust removal system: 4 pulse bag dust collectors are configured, and the dust collection efficiency exceeds 99%;

Spray dust reduction: Spray devices are installed in dust-prone areas such as belt conveyor drop points;

Belt conveyor dust cover: Full coverage to reduce the escape of materials during transportation.

3. Efficient execution and full-cycle service guarantee

The customer visited Liming Group three times in the early stage of the project. The technical team customized a plan that takes into account both production capacity and flexibility through more than ten in-depth communications. After production, Liming provides comprehensive operation training, including equipment maintenance, troubleshooting, etc., and establishes a 24-hour response mechanism to ensure the continuous and stable operation of the production line.

Through technological innovation and service collaboration, Liming Group not only helps customers build a high-yield, environmentally friendly modern production line, but also promotes the transformation of the sand and gravel industry to intelligence and green.

Previous: SMP Crusher

Next: SMP Crusher

The 1.2 million tons/year limestone crushing and sand making project designed by Liming for a customer has successfully created a high-yield, high-efficiency, energy-saving and environmentally friendly benchmark production line with advanced equipment

The 1.2 million tons/year limestone crushing and sand making project designed by Liming for a customer has successfully created a high-yield, high-efficiency, energy-saving and environmentally friendly benchmark production line with advanced equipment configuration, intelligent production methods and green environmental protection concepts.

1. Project Overview and High-standard Capacity Design

The project uses limestone as raw material, with a designed annual production capacity of 1.2 million tons, and operates 20 hours a day. The finished products include 0-3mm fine machine-made sand, 3-8mm melon seed slices and 8-31.5mm gravel, all of which are supplied to the mixing station. All three types of finished products have the characteristics of uniform particle shape and high compressive strength. Among them, the roundness and gradation of the machine-made sand are comparable to natural river sand, which has been highly recognized by the terminal market.

To ensure production capacity and quality, a combination of high-performance equipment from Liming was selected:

CI5X impact crusher is the core of coarse crushing, which has both high crushing ratio and low energy consumption characteristics;

VSI6X sand making machine is responsible for shaping sand making, optimizing the finished product particle shape through the dual modes of "stone hitting stone" and "stone hitting iron";

S5X vibrating screen realizes multi-level precise grading to ensure high screening efficiency of three specifications of aggregates.

2. Deep integration of intelligent and environmental protection technologies

1. Intelligent integrated control system

The production line adopts a central control design, and operators can monitor the equipment operation status, adjust parameters, and receive fault warnings in real time through the control room. For example, the rotor speed of the impact crusher, the feed volume of the sand making machine and other data can be remotely controlled, greatly reducing the need for manual intervention and improving production efficiency.

2. Green production full process coverage

The project adopts dry process to avoid sewage discharge problems from the source, and realizes dust through four major environmental protection measures:

Semi-sealed plant design: Crushing, screening and other major processes are carried out in a closed environment;

Dust removal system: 4 pulse bag dust collectors are configured, and the dust collection efficiency exceeds 99%;

Spray dust reduction: Spray devices are installed in dust-prone areas such as belt conveyor drop points;

Belt conveyor dust cover: Full coverage to reduce the escape of materials during transportation.

3. Efficient execution and full-cycle service guarantee

The customer visited Liming Group three times in the early stage of the project. The technical team customized a plan that takes into account both production capacity and flexibility through more than ten in-depth communications. After production, Liming provides comprehensive operation training, including equipment maintenance, troubleshooting, etc., and establishes a 24-hour response mechanism to ensure the continuous and stable operation of the production line.

Through technological innovation and service collaboration, Liming Group not only helps customers build a high-yield, environmentally friendly modern production line, but also promotes the transformation of the sand and gravel industry to intelligence and green.

Previous: SMP Crusher

Next: SMP Crusher

What are the complete equipment of sand production line

What are the complete equipment of sand production line What equipment to use for crushing hard rock

What equipment to use for crushing hard rock What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost? Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line What are the complete equipment of sand production line

What are the complete equipment of sand production line What equipment to use for crushing hard rock

What equipment to use for crushing hard rock What equipment is used in a 300 ton per hour granite production line? How much does it cost?

What equipment is used in a 300 ton per hour granite production line? How much does it cost? Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line

Liming helps Guangxi build a 1,000-ton-per-hour limestone crushing and sand-making production line Construction plan and equipment selection for 200 tons per hour river pebble sand production line

Construction plan and equipment selection for 200 tons per hour river pebble sand production line