The main component of quicklime is calcium oxide (CaO) (CalciumOxide; Lime; QuickLime).Quicklime generally contains overcooked lime, overcooked lime is slow to mature, if the lime slurry hardens and then occurs to mature, will be due

The main component of quicklime is calcium oxide (CaO) (CalciumOxide; Lime; QuickLime).

Quicklime generally contains overcooked lime, overcooked lime is slow to mature, if the lime slurry hardens and then occurs to mature, will be due to the expansion produced by the maturation of the bulge and cracking. In order to eliminate the hazards of overcooked lime, lime in the maturation, should also be "aged" for about 2 weeks. It is white, amorphous and absorbs water and carbon dioxide in the air. Calcium oxide and water to generate calcium hydroxide, and release heat. Soluble in acid water, insoluble in alcohol. It is an inorganic alkaline etching substance.

Quicklime is a common desiccant for removing water vapour by chemical absorption method, also used in iron and steel, pesticide, medicine, desiccant, tanning and dehydration of alcohol. It is especially suitable for puffed food, mushrooms, fungus and other local specialities, as well as products of instrumentation, medicine, clothing, electronic telecommunications, leather, textile and other industries. In addition, quicklime is used in large quantities as a building material and is also an important raw material for many industries.

The original production process of quicklime is to lay the quicklime and fuel in layers, the fire calcined for a week that is obtained. Modern use of mechanised, semi-mechanised mine mill slag and rotary kiln and other equipment for production. Calcination time is also correspondingly shortened, with rotary kiln production of lime only 2 to 4 hours, than with the mine mill slag production can improve productivity by more than 5 times. In recent years, and the emergence of cross-flow type, double slope type and burning oil ring row kiln and short rotary kiln with preheater and other energy-saving process and equipment, the fuel is also expanded to coal, coke, heavy oil or liquefied petroleum gas and so on.

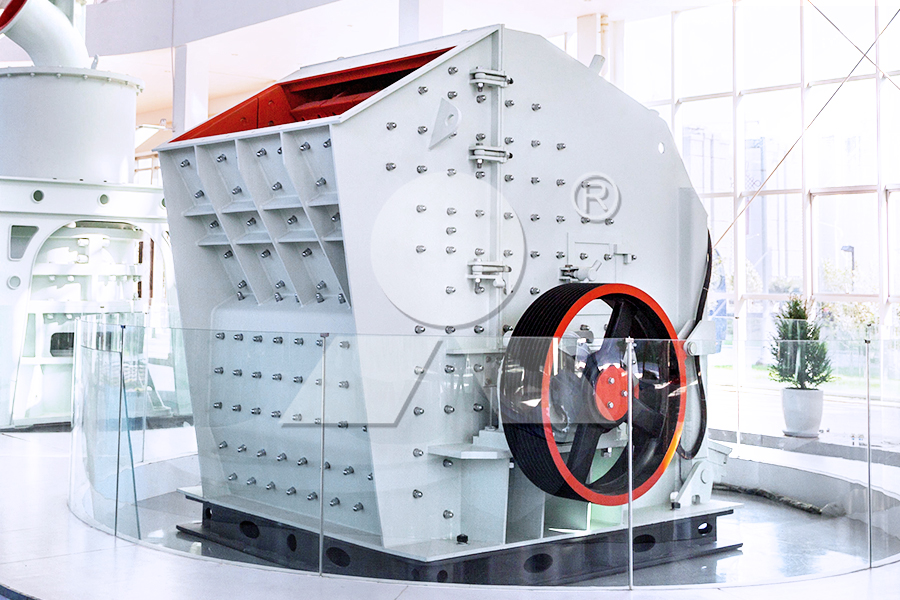

Related equipment

Jaw Crusher

Cone Crusher

Mobile Crusher

Previous: SMP Crusher

Next: SMP Crusher

The main component of quicklime is calcium oxide (CaO) (CalciumOxide; Lime; QuickLime).Quicklime generally contains overcooked lime, overcooked lime is slow to mature, if the lime slurry hardens and then occurs to mature, will be due

The main component of quicklime is calcium oxide (CaO) (CalciumOxide; Lime; QuickLime).

Quicklime generally contains overcooked lime, overcooked lime is slow to mature, if the lime slurry hardens and then occurs to mature, will be due to the expansion produced by the maturation of the bulge and cracking. In order to eliminate the hazards of overcooked lime, lime in the maturation, should also be "aged" for about 2 weeks. It is white, amorphous and absorbs water and carbon dioxide in the air. Calcium oxide and water to generate calcium hydroxide, and release heat. Soluble in acid water, insoluble in alcohol. It is an inorganic alkaline etching substance.

Quicklime is a common desiccant for removing water vapour by chemical absorption method, also used in iron and steel, pesticide, medicine, desiccant, tanning and dehydration of alcohol. It is especially suitable for puffed food, mushrooms, fungus and other local specialities, as well as products of instrumentation, medicine, clothing, electronic telecommunications, leather, textile and other industries. In addition, quicklime is used in large quantities as a building material and is also an important raw material for many industries.

The original production process of quicklime is to lay the quicklime and fuel in layers, the fire calcined for a week that is obtained. Modern use of mechanised, semi-mechanised mine mill slag and rotary kiln and other equipment for production. Calcination time is also correspondingly shortened, with rotary kiln production of lime only 2 to 4 hours, than with the mine mill slag production can improve productivity by more than 5 times. In recent years, and the emergence of cross-flow type, double slope type and burning oil ring row kiln and short rotary kiln with preheater and other energy-saving process and equipment, the fuel is also expanded to coal, coke, heavy oil or liquefied petroleum gas and so on.

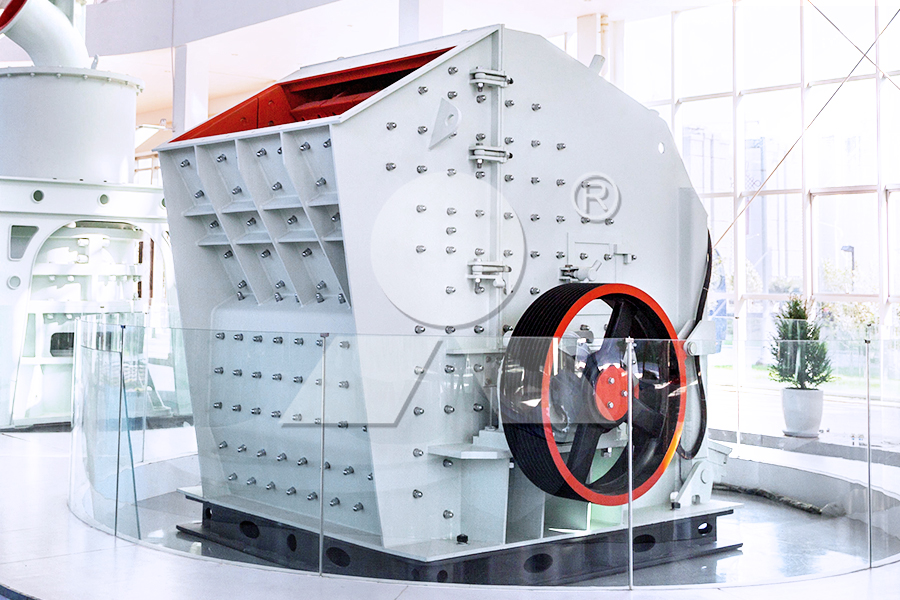

Related equipment

Jaw Crusher

Cone Crusher

Mobile Crusher

Previous: SMP Crusher

Next: SMP Crusher

Steel Grit Comprehensive Performance Steel Grit Processing Procedures

Steel Grit Comprehensive Performance Steel Grit Processing Procedures Investment Prospects and Beneficiation Processes for Coal Uses

Investment Prospects and Beneficiation Processes for Coal Uses Aluminium sulphate beneficiation process and main uses

Aluminium sulphate beneficiation process and main uses Chrome Ore Characteristics Uses and Beneficiation Plus Equipment

Chrome Ore Characteristics Uses and Beneficiation Plus Equipment Mercury ore beneficiation process and characteristics

Mercury ore beneficiation process and characteristics Steel Grit Comprehensive Performance Steel Grit Processing Procedures

Steel Grit Comprehensive Performance Steel Grit Processing Procedures Investment Prospects and Beneficiation Processes for Coal Uses

Investment Prospects and Beneficiation Processes for Coal Uses Aluminium sulphate beneficiation process and main uses

Aluminium sulphate beneficiation process and main uses Chrome Ore Characteristics Uses and Beneficiation Plus Equipment

Chrome Ore Characteristics Uses and Beneficiation Plus Equipment Mercury ore beneficiation process and characteristics

Mercury ore beneficiation process and characteristics