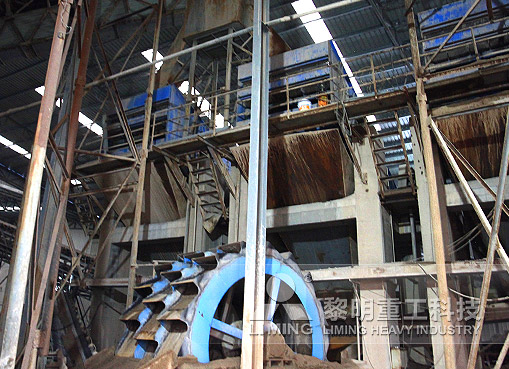

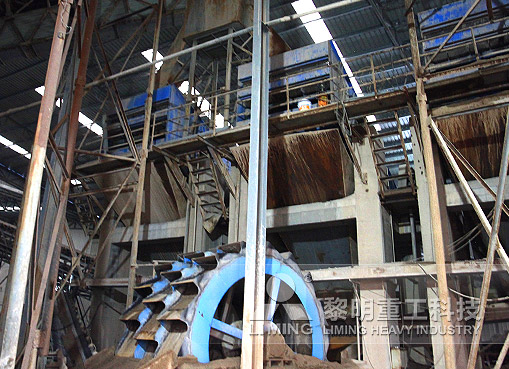

The complete set of equipment for the sand and gravel production line mainly includes the following types:1. Crushing equipmentJaw crusher: As the primary crushing equipment, it is used for coarse crushing of large pieces of r

The complete set of equipment for the sand and gravel production line mainly includes the following types:

1. Crushing equipment

Jaw crusher: As the primary crushing equipment, it is used for coarse crushing of large pieces of raw materials. It has large feed particle size, strong processing capacity, simple structure, stable and reliable operation, and is widely used in building materials, roads, railways and other industries.

Cone crusher: Suitable for medium and fine crushing of raw materials with medium or higher hardness, such as river pebbles, granite, basalt, etc. It has the characteristics of high production efficiency, long service life, and green environmental protection.

Impact crusher: More suitable for processing materials with lower hardness such as limestone, bluestone, coal gangue, weathered rock, etc. It has the advantages of simple structure, convenient maintenance, good finished product particle shape, and low investment cost.

2. Screening equipment

Circular vibrating screen: Used to screen the crushed materials and separate sand and gravel of different particle sizes. It has the characteristics of high screening efficiency and large processing capacity, which can ensure the stable operation of the production line.

3. Sand making equipment

Vertical shaft impact sand making machine: The crushed stone after fine crushing is further crushed into sand that meets the requirements. It has the function of shaping, and the finished products have good particle shape and coordinated gradation, meeting the high-standard aggregate requirements.

4. Feeding and conveying equipment

Vibrating feeder: As a raw material supply device, it feeds raw materials such as gravel and sand into the crushing equipment evenly, quantitatively and continuously. It has the characteristics of stable vibration, low energy consumption and uniform feeding.

Belt conveyor: As a "link" connecting various links, it efficiently transmits materials between various equipment. It has the advantages of long conveying distance, large conveying capacity and reliable operation.

5. Sand washing and dust removal equipment (optional)

Sand washing machine: used to clean sand and gravel, remove impurities such as soil and stone powder, and improve the quality of sand and gravel.

Dust removal system: including fans, motors, dust treatment and recovery systems, etc., used to collect and treat dust generated during the production process to reduce dust pollution to the environment.

Previous: SMP Crusher

Next: SMP Crusher

The complete set of equipment for the sand and gravel production line mainly includes the following types:1. Crushing equipmentJaw crusher: As the primary crushing equipment, it is used for coarse crushing of large pieces of r

The complete set of equipment for the sand and gravel production line mainly includes the following types:

1. Crushing equipment

Jaw crusher: As the primary crushing equipment, it is used for coarse crushing of large pieces of raw materials. It has large feed particle size, strong processing capacity, simple structure, stable and reliable operation, and is widely used in building materials, roads, railways and other industries.

Cone crusher: Suitable for medium and fine crushing of raw materials with medium or higher hardness, such as river pebbles, granite, basalt, etc. It has the characteristics of high production efficiency, long service life, and green environmental protection.

Impact crusher: More suitable for processing materials with lower hardness such as limestone, bluestone, coal gangue, weathered rock, etc. It has the advantages of simple structure, convenient maintenance, good finished product particle shape, and low investment cost.

2. Screening equipment

Circular vibrating screen: Used to screen the crushed materials and separate sand and gravel of different particle sizes. It has the characteristics of high screening efficiency and large processing capacity, which can ensure the stable operation of the production line.

3. Sand making equipment

Vertical shaft impact sand making machine: The crushed stone after fine crushing is further crushed into sand that meets the requirements. It has the function of shaping, and the finished products have good particle shape and coordinated gradation, meeting the high-standard aggregate requirements.

4. Feeding and conveying equipment

Vibrating feeder: As a raw material supply device, it feeds raw materials such as gravel and sand into the crushing equipment evenly, quantitatively and continuously. It has the characteristics of stable vibration, low energy consumption and uniform feeding.

Belt conveyor: As a "link" connecting various links, it efficiently transmits materials between various equipment. It has the advantages of long conveying distance, large conveying capacity and reliable operation.

5. Sand washing and dust removal equipment (optional)

Sand washing machine: used to clean sand and gravel, remove impurities such as soil and stone powder, and improve the quality of sand and gravel.

Dust removal system: including fans, motors, dust treatment and recovery systems, etc., used to collect and treat dust generated during the production process to reduce dust pollution to the environment.

Previous: SMP Crusher

Next: SMP Crusher

What is the efficiency of the complete set of equipment for the sand and gravel production line?

What is the efficiency of the complete set of equipment for the sand and gravel production line? The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development What is the efficiency of the complete set of equipment for the sand and gravel production line?

What is the efficiency of the complete set of equipment for the sand and gravel production line? The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development