Nickel ore, because of its rich reserves, occupies an important position in the metal industry. The following introduces how nickel ore is crushed and which crushing equipment is selected:Nickel ore crushing process:Nickel ore

Nickel ore, because of its rich reserves, occupies an important position in the metal industry. The following introduces how nickel ore is crushed and which crushing equipment is selected:

Nickel ore crushing process:

Nickel ore crushing process is a key step in the refining process, which mainly contains two stages of crushing and screening. Firstly, the raw nickel ore is fed into the jaw crusher for preliminary rough crushing through the feeder, this step is to crush the ore to a size suitable for further processing. Next, the roughly crushed ore is fed into the cone crusher through the conveying equipment for finer medium and fine crushing.

After the medium to fine crushing, the ore enters the screening plant for particle size screening. During the screening process, the ore with a particle size of less than 20mm is recognised as a qualified product and will be sent to the finished product pile for further processing; while the ore with a particle size of more than 20mm will be returned to the cone crusher and crushed again until it reaches the required particle size. The whole crushing process ensures the uniform particle size of nickel ore, which provides a strong guarantee for the subsequent processing.

The following equipment is mainly used for nickel ore crushing:

1, Jaw Crusher:

Jaw crusher is a high-efficiency coarse crushing equipment, features include high-efficiency crushing chamber, combined frame, integrated motor, no foot support, hydraulic adjustment, centralised lubrication, stable operation is more suitable for nickel ore. Recommended models C6X160, C6X200, hourly output of 410-1150 tonnes, 610-1510 tonnes respectively.

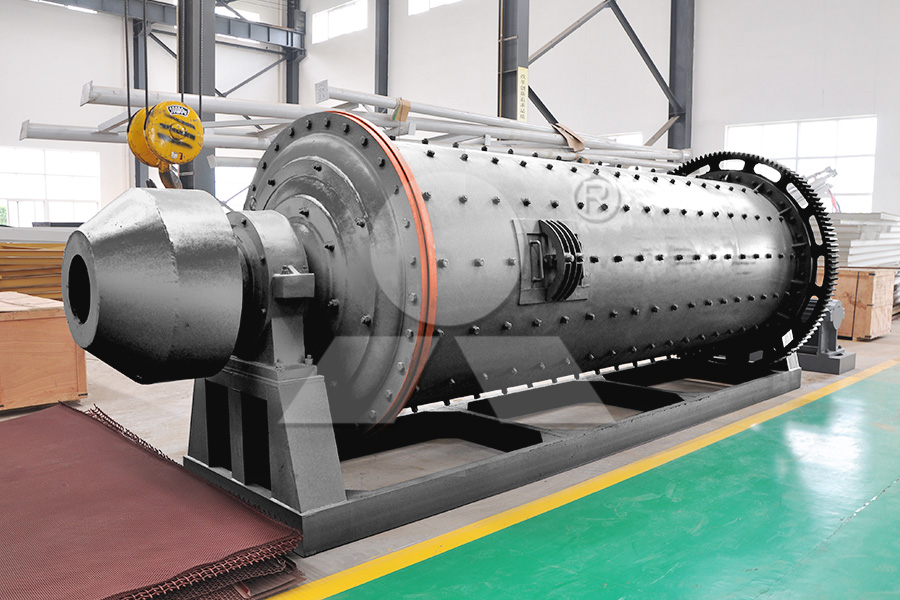

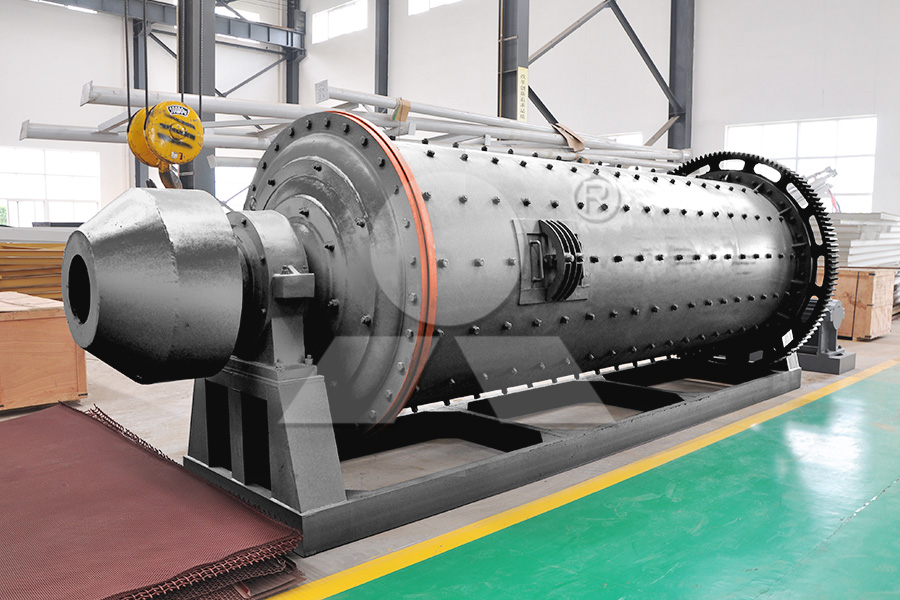

2、Cone crusher:

Cone crusher is the preferred equipment in the field of medium and fine crushing, and its laminated crushing technology ensures excellent grain shape of the finished material. It adopts wear parts made of high wear-resistant material, which effectively prolongs the service life and reduces the production cost. The equipment is highly intelligent and easy to operate. Recommended models for crushing nickel ores include HST315 (S1 cavity type) of single-cylinder series, with a capacity of 335-1050 tonnes per hour, and HPT800 (C1, C2 cavity type) of multi-cylinder series, with a capacity of 520-1200 tonnes per hour.

Previous: SMP Crusher

Next: SMP Crusher

Nickel ore, because of its rich reserves, occupies an important position in the metal industry. The following introduces how nickel ore is crushed and which crushing equipment is selected:Nickel ore crushing process:Nickel ore

Nickel ore, because of its rich reserves, occupies an important position in the metal industry. The following introduces how nickel ore is crushed and which crushing equipment is selected:

Nickel ore crushing process:

Nickel ore crushing process is a key step in the refining process, which mainly contains two stages of crushing and screening. Firstly, the raw nickel ore is fed into the jaw crusher for preliminary rough crushing through the feeder, this step is to crush the ore to a size suitable for further processing. Next, the roughly crushed ore is fed into the cone crusher through the conveying equipment for finer medium and fine crushing.

After the medium to fine crushing, the ore enters the screening plant for particle size screening. During the screening process, the ore with a particle size of less than 20mm is recognised as a qualified product and will be sent to the finished product pile for further processing; while the ore with a particle size of more than 20mm will be returned to the cone crusher and crushed again until it reaches the required particle size. The whole crushing process ensures the uniform particle size of nickel ore, which provides a strong guarantee for the subsequent processing.

The following equipment is mainly used for nickel ore crushing:

1, Jaw Crusher:

Jaw crusher is a high-efficiency coarse crushing equipment, features include high-efficiency crushing chamber, combined frame, integrated motor, no foot support, hydraulic adjustment, centralised lubrication, stable operation is more suitable for nickel ore. Recommended models C6X160, C6X200, hourly output of 410-1150 tonnes, 610-1510 tonnes respectively.

2、Cone crusher:

Cone crusher is the preferred equipment in the field of medium and fine crushing, and its laminated crushing technology ensures excellent grain shape of the finished material. It adopts wear parts made of high wear-resistant material, which effectively prolongs the service life and reduces the production cost. The equipment is highly intelligent and easy to operate. Recommended models for crushing nickel ores include HST315 (S1 cavity type) of single-cylinder series, with a capacity of 335-1050 tonnes per hour, and HPT800 (C1, C2 cavity type) of multi-cylinder series, with a capacity of 520-1200 tonnes per hour.

Previous: SMP Crusher

Next: SMP Crusher

Nickel ore crushing process and 200 t/h production line configuration

Nickel ore crushing process and 200 t/h production line configuration What equipment to choose for iron ore crushing

What equipment to choose for iron ore crushing 200t h Copper Ore Crushing Line Configuration Plan and Process Flow

200t h Copper Ore Crushing Line Configuration Plan and Process Flow Northeast Xilin 5000 tonnes per day lead and zinc ore crushing and processing line

Northeast Xilin 5000 tonnes per day lead and zinc ore crushing and processing line Manganese ore crushing treatment process and equipment application

Manganese ore crushing treatment process and equipment application Nickel ore crushing process and 200 t/h production line configuration

Nickel ore crushing process and 200 t/h production line configuration What equipment to choose for iron ore crushing

What equipment to choose for iron ore crushing 200t h Copper Ore Crushing Line Configuration Plan and Process Flow

200t h Copper Ore Crushing Line Configuration Plan and Process Flow Northeast Xilin 5000 tonnes per day lead and zinc ore crushing and processing line

Northeast Xilin 5000 tonnes per day lead and zinc ore crushing and processing line Manganese ore crushing treatment process and equipment application

Manganese ore crushing treatment process and equipment application