With the increasing demands for finished aggregate quality in the Jiangsu, Zhejiang, and Shanghai sand and gravel end-user markets, Haixin Mining Company keenly recognized this market shift and actively transformed its production strategy, proposing to

With the increasing demands for finished aggregate quality in the Jiangsu, Zhejiang, and Shanghai sand and gravel end-user markets, Haixin Mining Company keenly recognized this market shift and actively transformed its production strategy, proposing to upgrade its manufactured sand production line to improve capacity and product quality.

More Sand and Gravel Equipment Upgrade Plans

Project Background

To meet increasingly stringent market quality requirements, Haixin Mining decided to upgrade its existing production line. Especially for raw materials with high compressive strength, such as tuff (average 272 MPa for limestone and 155 MPa for fine porphyry), they aimed to increase manufactured sand production capacity while ensuring high-quality finished aggregates.

Technical Upgrade Measures

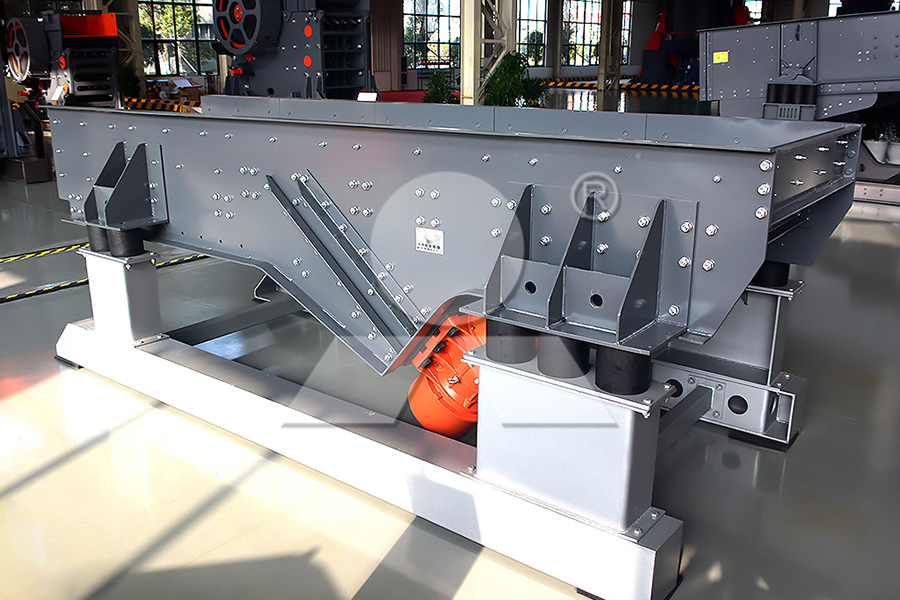

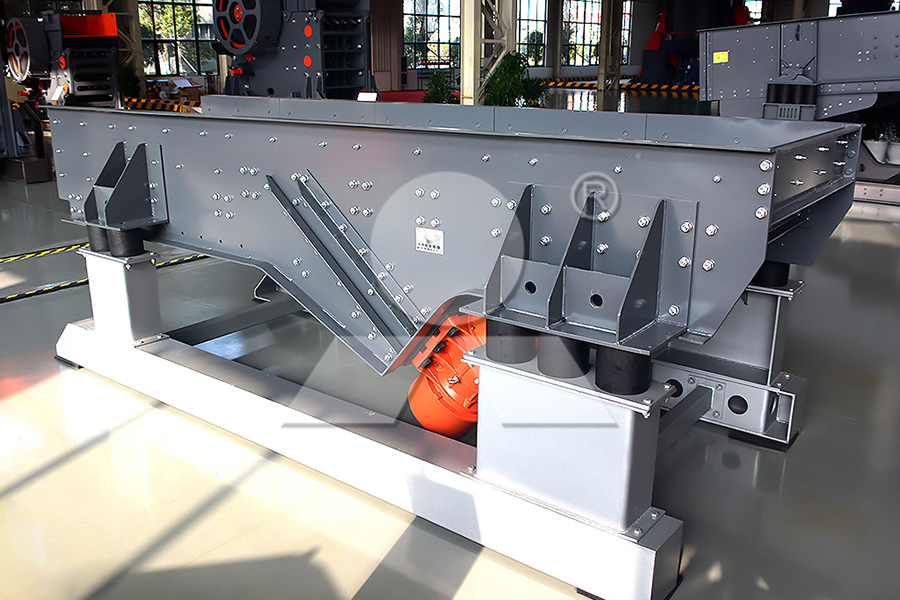

1. Introduction of Advanced Equipment: To meet the client's needs, the fine crushing stage adopted the HPT multi-cylinder hydraulic laminated cone crusher from Shibang Group. This equipment is highly efficient and stable, effectively handling high-strength tuff in the fine crushing stage.

2. Improved Equipment Performance: After a series of technical demonstrations and optimizations, Shibang Group's technical personnel increased the linear speed of the impact crusher in the production line by 15%. This adjustment not only increased the production capacity of manufactured sand but also significantly improved its quality, including particle shape and gradation.

3. Enhanced Overall Benefits: Through this technological reform, the production capacity of manufactured sand increased by 10%, while the quality also saw a significant improvement. High-quality manufactured sand better meets market demand, giving Haixin Mining a competitive edge in the fierce market competition.

Owner Feedback: This upgrade project not only achieved the expected production capacity increase target but also significantly improved the quality of finished aggregates, fully meeting the market demand for high-quality sand and gravel. Haixin Mining highly appreciates the technical support and equipment performance provided by Shibang Group and looks forward to continued cooperation on more projects in the future.

Conclusion: Through this technological reform, the Liulishan Mine tuff crushing and sand making project of Zhejiang Jiaotong Mining has achieved a dual improvement in both production capacity and quality. Shibang Group, with its advanced equipment and professional technical support, helps mining companies continuously achieve new breakthroughs in market competition.

Previous: SMP Crusher

Next: SMP Crusher

With the increasing demands for finished aggregate quality in the Jiangsu, Zhejiang, and Shanghai sand and gravel end-user markets, Haixin Mining Company keenly recognized this market shift and actively transformed its production strategy, proposing to

With the increasing demands for finished aggregate quality in the Jiangsu, Zhejiang, and Shanghai sand and gravel end-user markets, Haixin Mining Company keenly recognized this market shift and actively transformed its production strategy, proposing to upgrade its manufactured sand production line to improve capacity and product quality.

More Sand and Gravel Equipment Upgrade Plans

Project Background

To meet increasingly stringent market quality requirements, Haixin Mining decided to upgrade its existing production line. Especially for raw materials with high compressive strength, such as tuff (average 272 MPa for limestone and 155 MPa for fine porphyry), they aimed to increase manufactured sand production capacity while ensuring high-quality finished aggregates.

Technical Upgrade Measures

1. Introduction of Advanced Equipment: To meet the client's needs, the fine crushing stage adopted the HPT multi-cylinder hydraulic laminated cone crusher from Shibang Group. This equipment is highly efficient and stable, effectively handling high-strength tuff in the fine crushing stage.

2. Improved Equipment Performance: After a series of technical demonstrations and optimizations, Shibang Group's technical personnel increased the linear speed of the impact crusher in the production line by 15%. This adjustment not only increased the production capacity of manufactured sand but also significantly improved its quality, including particle shape and gradation.

3. Enhanced Overall Benefits: Through this technological reform, the production capacity of manufactured sand increased by 10%, while the quality also saw a significant improvement. High-quality manufactured sand better meets market demand, giving Haixin Mining a competitive edge in the fierce market competition.

Owner Feedback: This upgrade project not only achieved the expected production capacity increase target but also significantly improved the quality of finished aggregates, fully meeting the market demand for high-quality sand and gravel. Haixin Mining highly appreciates the technical support and equipment performance provided by Shibang Group and looks forward to continued cooperation on more projects in the future.

Conclusion: Through this technological reform, the Liulishan Mine tuff crushing and sand making project of Zhejiang Jiaotong Mining has achieved a dual improvement in both production capacity and quality. Shibang Group, with its advanced equipment and professional technical support, helps mining companies continuously achieve new breakthroughs in market competition.

Previous: SMP Crusher

Next: SMP Crusher

What are some large-scale stone crushers with a daily output of 10,000 tons?

What are some large-scale stone crushers with a daily output of 10,000 tons? How much does a dolomite crushing and sand making equipment cost? A detailed explanation of a crushing production line with an hourly output of 400-500 tons.

How much does a dolomite crushing and sand making equipment cost? A detailed explanation of a crushing production line with an hourly output of 400-500 tons. A limestone crushing and sand making production line with an annual output of 12 million tons.

A limestone crushing and sand making production line with an annual output of 12 million tons. How much does a mobile crushing plant cost? What factors influence the price?

How much does a mobile crushing plant cost? What factors influence the price? Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases

Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases What are some large-scale stone crushers with a daily output of 10,000 tons?

What are some large-scale stone crushers with a daily output of 10,000 tons? How much does a dolomite crushing and sand making equipment cost? A detailed explanation of a crushing production line with an hourly output of 400-500 tons.

How much does a dolomite crushing and sand making equipment cost? A detailed explanation of a crushing production line with an hourly output of 400-500 tons. A limestone crushing and sand making production line with an annual output of 12 million tons.

A limestone crushing and sand making production line with an annual output of 12 million tons. How much does a mobile crushing plant cost? What factors influence the price?

How much does a mobile crushing plant cost? What factors influence the price? Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases

Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases