At the moment when the sand and gravel industry is booming, both large-scale infrastructure projects and daily construction projects cannot do without the support of high-quality sand and gravel aggregates. As the "birthplace" of sand and gra

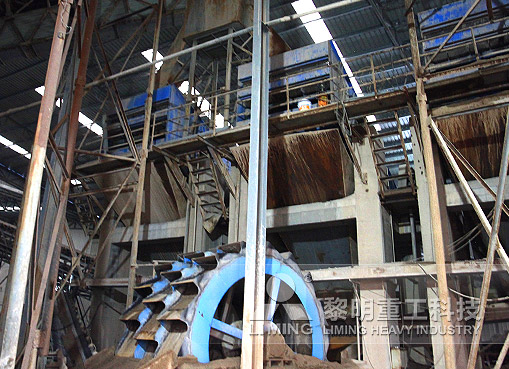

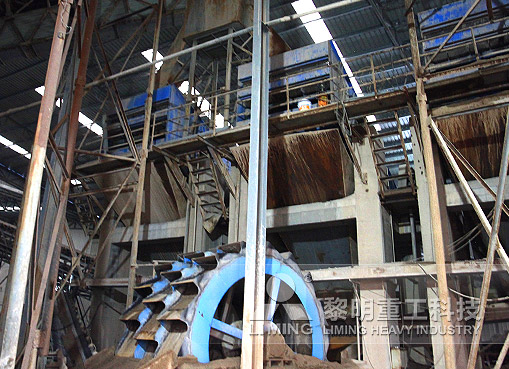

At the moment when the sand and gravel industry is booming, both large-scale infrastructure projects and daily construction projects cannot do without the support of high-quality sand and gravel aggregates. As the "birthplace" of sand and gravel aggregates, the gravel plant's gravel production line is like a precise "production dragon". All equipment links work closely together to continuously output high-quality sand and gravel. Today, let's take a deep look at the indispensable common equipment in the gravel production line of the sand and gravel plant.

Pioneer of coarse crushing-jaw crusher

The jaw crusher can be called the "pioneer" of the gravel production line of the sand and gravel plant. It is like a powerful "giant" with a sturdy jaw plate and strong crushing force. When a large piece of raw stone enters its "mouth", the jaw plate exerts huge pressure on the raw stone through periodic opening and closing movements, and initially crushes it into smaller stones.

This crushing method is simple and direct, with extremely high efficiency, and can handle raw stones of various hardness, whether it is hard granite or slightly soft limestone. Moreover, the structure of the jaw crusher is relatively simple, easy to maintain, and low in cost. It is the preferred equipment for the coarse crushing link of the sand and gravel plant, laying a good foundation for the subsequent crushing process.

Expert in medium and fine crushing - cone crusher

After the coarse crushing of the jaw crusher, the stones need to be further refined, and then it is the turn of the cone crusher to appear. The cone crusher is like a skilled "craftsman". It uses the rotation and extrusion of the cone cavity to perform fine medium and fine crushing on the stones.

The cone crusher has the characteristics of large crushing ratio and uniform product particle size. It can accurately control the particle size of the discharge by adjusting the size of the discharge port according to different production needs. At the same time, the cone crusher adopts advanced hydraulic protection and automatic control systems, which can automatically adjust when encountering overload or foreign matter, ensure the safe operation of the equipment, and greatly improve the stability and reliability of production. In large sand and gravel plants, cone crushers are often the core equipment in the medium and fine crushing link, providing a strong guarantee for the production of high-quality sand and gravel aggregates.

Shaping sand making expert - impact sand making machine

If you want to get machine-made sand with rounded particles and reasonable grading, the impact sand making machine is an indispensable "shaping expert". It adopts the crushing principle of combining "stone hitting stone" and "stone hitting iron", and throws the material through the high-speed rotating impeller, so that the material can be crushed and shaped in the process of mutual collision or collision with the impact plate.

The machine-made sand produced by the impact sand making machine has good particle shape and low needle-like content, which fully meets the national standards for building sand. Moreover, it can flexibly adjust the working parameters according to different raw materials and product requirements to produce machine-made sand of different particle sizes to meet the diverse needs of the market. In the sand and gravel plant, the impact sand making machine is like a bright "pearl", playing a key role in the production of high-quality machine-made sand.

Screening "gatekeeper" - vibrating screen

In the process of crushing and sand making, materials of different particle sizes will be produced. In order to classify these materials according to particle size, the vibrating screen comes in handy. The vibrating screen is like a strict "gatekeeper". It uses the exciting force generated by the vibrating motor to make the material on the screen surface do continuous jumping motion, thereby realizing the screening of the material.

The vibrating screen has the characteristics of high screening efficiency and large processing capacity. It can set up multiple layers of screens to separate the material into products of various particle sizes, such as coarse sand, medium sand, fine sand, etc. At the same time, the vibrating screen has a simple structure, stable operation, and easy maintenance. It is an important equipment in the sand and gravel plant to ensure product quality and production efficiency.

Conveying "link"-belt conveyor

In the entire gravel production line, materials need to be efficiently transmitted between various equipment. At this time, the belt conveyor becomes the "link" connecting various links. It is like a long "conveyor belt", which transports the raw stone from the jaw crusher to the cone crusher, and then transports the crushed material to the vibrating screen for screening, and finally transports the qualified sand and gravel products to the designated location.

The belt conveyor has the advantages of long conveying distance, large conveying capacity, and reliable operation. It can be customized according to the actual needs of the production site and flexibly arranged between various equipment to ensure the smooth transmission of materials, thereby improving the automation and production efficiency of the entire production line.

These commonly used equipment in the gravel production line of the sand and gravel plant are like a closely coordinated team, each playing a unique role and working together to produce high-quality sand and gravel aggregates. With the continuous advancement of science and technology, these equipment are also constantly innovating and upgrading, injecting new impetus into the development of the sand and gravel industry. If you are also interested in the sand and gravel industry, you may wish to learn more about these "gold digging tools" and start your own sand and gravel career journey!

Previous: SMP Crusher

Next: SMP Crusher

At the moment when the sand and gravel industry is booming, both large-scale infrastructure projects and daily construction projects cannot do without the support of high-quality sand and gravel aggregates. As the "birthplace" of sand and gra

At the moment when the sand and gravel industry is booming, both large-scale infrastructure projects and daily construction projects cannot do without the support of high-quality sand and gravel aggregates. As the "birthplace" of sand and gravel aggregates, the gravel plant's gravel production line is like a precise "production dragon". All equipment links work closely together to continuously output high-quality sand and gravel. Today, let's take a deep look at the indispensable common equipment in the gravel production line of the sand and gravel plant.

Pioneer of coarse crushing-jaw crusher

The jaw crusher can be called the "pioneer" of the gravel production line of the sand and gravel plant. It is like a powerful "giant" with a sturdy jaw plate and strong crushing force. When a large piece of raw stone enters its "mouth", the jaw plate exerts huge pressure on the raw stone through periodic opening and closing movements, and initially crushes it into smaller stones.

This crushing method is simple and direct, with extremely high efficiency, and can handle raw stones of various hardness, whether it is hard granite or slightly soft limestone. Moreover, the structure of the jaw crusher is relatively simple, easy to maintain, and low in cost. It is the preferred equipment for the coarse crushing link of the sand and gravel plant, laying a good foundation for the subsequent crushing process.

Expert in medium and fine crushing - cone crusher

After the coarse crushing of the jaw crusher, the stones need to be further refined, and then it is the turn of the cone crusher to appear. The cone crusher is like a skilled "craftsman". It uses the rotation and extrusion of the cone cavity to perform fine medium and fine crushing on the stones.

The cone crusher has the characteristics of large crushing ratio and uniform product particle size. It can accurately control the particle size of the discharge by adjusting the size of the discharge port according to different production needs. At the same time, the cone crusher adopts advanced hydraulic protection and automatic control systems, which can automatically adjust when encountering overload or foreign matter, ensure the safe operation of the equipment, and greatly improve the stability and reliability of production. In large sand and gravel plants, cone crushers are often the core equipment in the medium and fine crushing link, providing a strong guarantee for the production of high-quality sand and gravel aggregates.

Shaping sand making expert - impact sand making machine

If you want to get machine-made sand with rounded particles and reasonable grading, the impact sand making machine is an indispensable "shaping expert". It adopts the crushing principle of combining "stone hitting stone" and "stone hitting iron", and throws the material through the high-speed rotating impeller, so that the material can be crushed and shaped in the process of mutual collision or collision with the impact plate.

The machine-made sand produced by the impact sand making machine has good particle shape and low needle-like content, which fully meets the national standards for building sand. Moreover, it can flexibly adjust the working parameters according to different raw materials and product requirements to produce machine-made sand of different particle sizes to meet the diverse needs of the market. In the sand and gravel plant, the impact sand making machine is like a bright "pearl", playing a key role in the production of high-quality machine-made sand.

Screening "gatekeeper" - vibrating screen

In the process of crushing and sand making, materials of different particle sizes will be produced. In order to classify these materials according to particle size, the vibrating screen comes in handy. The vibrating screen is like a strict "gatekeeper". It uses the exciting force generated by the vibrating motor to make the material on the screen surface do continuous jumping motion, thereby realizing the screening of the material.

The vibrating screen has the characteristics of high screening efficiency and large processing capacity. It can set up multiple layers of screens to separate the material into products of various particle sizes, such as coarse sand, medium sand, fine sand, etc. At the same time, the vibrating screen has a simple structure, stable operation, and easy maintenance. It is an important equipment in the sand and gravel plant to ensure product quality and production efficiency.

Conveying "link"-belt conveyor

In the entire gravel production line, materials need to be efficiently transmitted between various equipment. At this time, the belt conveyor becomes the "link" connecting various links. It is like a long "conveyor belt", which transports the raw stone from the jaw crusher to the cone crusher, and then transports the crushed material to the vibrating screen for screening, and finally transports the qualified sand and gravel products to the designated location.

The belt conveyor has the advantages of long conveying distance, large conveying capacity, and reliable operation. It can be customized according to the actual needs of the production site and flexibly arranged between various equipment to ensure the smooth transmission of materials, thereby improving the automation and production efficiency of the entire production line.

These commonly used equipment in the gravel production line of the sand and gravel plant are like a closely coordinated team, each playing a unique role and working together to produce high-quality sand and gravel aggregates. With the continuous advancement of science and technology, these equipment are also constantly innovating and upgrading, injecting new impetus into the development of the sand and gravel industry. If you are also interested in the sand and gravel industry, you may wish to learn more about these "gold digging tools" and start your own sand and gravel career journey!

Previous: SMP Crusher

Next: SMP Crusher

Common equipment for sand and gravel production line

Common equipment for sand and gravel production line What are the complete equipment of sand and gravel production line?

What are the complete equipment of sand and gravel production line? What is the efficiency of the complete set of equipment for the sand and gravel production line?

What is the efficiency of the complete set of equipment for the sand and gravel production line? The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line Common equipment for sand and gravel production line

Common equipment for sand and gravel production line What are the complete equipment of sand and gravel production line?

What are the complete equipment of sand and gravel production line? What is the efficiency of the complete set of equipment for the sand and gravel production line?

What is the efficiency of the complete set of equipment for the sand and gravel production line? The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line