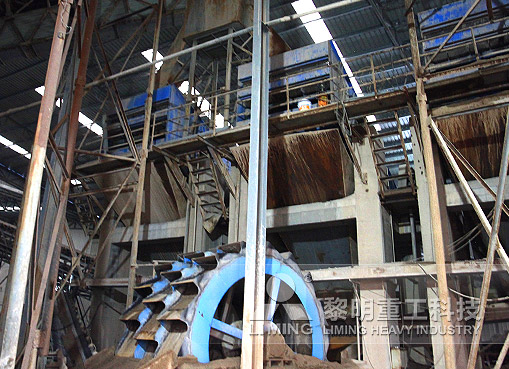

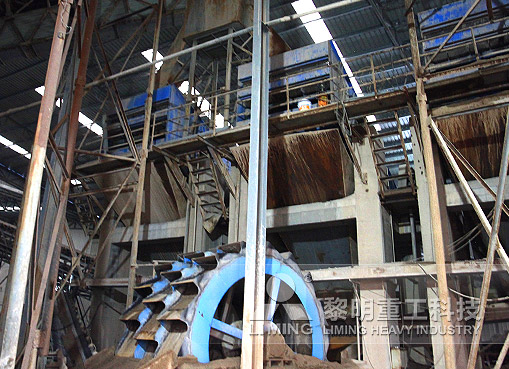

Common equipment in sand and gravel production lines can be divided into crushing system, screening system, sand making system, storage and transportation system, dust removal system, etc. according to their functions. The following is a detailed intro

Common equipment in sand and gravel production lines can be divided into crushing system, screening system, sand making system, storage and transportation system, dust removal system, etc. according to their functions. The following is a detailed introduction for you:

Crushing system

Jaw crusher: commonly used for primary crushing, coarse crushing of large stones with a particle size of up to 1500mm, and can produce 1-2200 tons of crushed stone per hour. It has the characteristics of large crushing ratio, simple structure, stable and reliable operation, large feed volume and throughput, strong processing capacity, small footprint, good finished product particle shape, and is widely used in building materials, roads, railways and other industries.

Cone crusher: It is a popular secondary crushing equipment, suitable for processing materials with higher hardness, such as river pebbles, granite, basalt, etc. It can perform medium and fine crushing of stones with a particle size not exceeding 230mm, and can produce 12-700 tons of crushed stone per hour. It has the advantages of high production efficiency, long service life, and green environmental protection. It is widely used in metallurgy, construction, roads and other industries.

Impact crusher: Also as a secondary crushing equipment, it is more suitable for processing materials with lower hardness such as limestone, bluestone, coal gangue, weathered rock, etc. Its feed size is slightly higher than that of the cone crusher, up to 800mm, and its production capacity is 30-800t/h. It has the characteristics of simple structure, convenient maintenance, good finished product shape, and low investment cost. It is widely used in cement, building materials, chemicals, coal and other industries.

Screening system

The commonly used equipment is a circular vibrating screen, which is used to screen the crushed materials and separate sand and gravel of different particle sizes. It has the characteristics of high screening efficiency and large processing capacity, which can ensure the stable operation of the production line. There are almost no other vulnerable parts except the screen, which is simple to use and easy to maintain.

Sand making system

The vertical shaft impact sand making machine is a commonly used sand making machine on the market. It can further crush the crushed stone with a particle size of no more than 50mm after fine crushing into 30 mesh sand, and can produce 60-650 tons of sand per hour. It has both shaping functions, and the finished products have good particle shape and are easy to sell at a good price. It can ensure that the sand and gravel produced are uniform in particle size and coordinated in gradation, meeting the high-standard aggregate requirements.

Storage and transportation system

Silo: used to store raw materials and finished sand and gravel, plays a role in buffering and regulating production, and ensures the continuity of production.

Belt conveyor: as a "link" connecting various links, it efficiently transfers materials between various equipment. It can be customized according to the actual needs of the production site and flexibly arranged between various equipment. It has the advantages of long conveying distance, large conveying capacity, and reliable operation, ensuring smooth material transmission and improving the automation and production efficiency of the entire production line.

Dust removal system

Including fans, motors, dust treatment and recovery systems, etc., used to collect and treat dust generated during the production process, reduce dust pollution to the environment, protect the health of workers, and at the same time realize dust recycling and reduce production costs.

Previous: SMP Crusher

Next: SMP Crusher

Common equipment in sand and gravel production lines can be divided into crushing system, screening system, sand making system, storage and transportation system, dust removal system, etc. according to their functions. The following is a detailed intro

Common equipment in sand and gravel production lines can be divided into crushing system, screening system, sand making system, storage and transportation system, dust removal system, etc. according to their functions. The following is a detailed introduction for you:

Crushing system

Jaw crusher: commonly used for primary crushing, coarse crushing of large stones with a particle size of up to 1500mm, and can produce 1-2200 tons of crushed stone per hour. It has the characteristics of large crushing ratio, simple structure, stable and reliable operation, large feed volume and throughput, strong processing capacity, small footprint, good finished product particle shape, and is widely used in building materials, roads, railways and other industries.

Cone crusher: It is a popular secondary crushing equipment, suitable for processing materials with higher hardness, such as river pebbles, granite, basalt, etc. It can perform medium and fine crushing of stones with a particle size not exceeding 230mm, and can produce 12-700 tons of crushed stone per hour. It has the advantages of high production efficiency, long service life, and green environmental protection. It is widely used in metallurgy, construction, roads and other industries.

Impact crusher: Also as a secondary crushing equipment, it is more suitable for processing materials with lower hardness such as limestone, bluestone, coal gangue, weathered rock, etc. Its feed size is slightly higher than that of the cone crusher, up to 800mm, and its production capacity is 30-800t/h. It has the characteristics of simple structure, convenient maintenance, good finished product shape, and low investment cost. It is widely used in cement, building materials, chemicals, coal and other industries.

Screening system

The commonly used equipment is a circular vibrating screen, which is used to screen the crushed materials and separate sand and gravel of different particle sizes. It has the characteristics of high screening efficiency and large processing capacity, which can ensure the stable operation of the production line. There are almost no other vulnerable parts except the screen, which is simple to use and easy to maintain.

Sand making system

The vertical shaft impact sand making machine is a commonly used sand making machine on the market. It can further crush the crushed stone with a particle size of no more than 50mm after fine crushing into 30 mesh sand, and can produce 60-650 tons of sand per hour. It has both shaping functions, and the finished products have good particle shape and are easy to sell at a good price. It can ensure that the sand and gravel produced are uniform in particle size and coordinated in gradation, meeting the high-standard aggregate requirements.

Storage and transportation system

Silo: used to store raw materials and finished sand and gravel, plays a role in buffering and regulating production, and ensures the continuity of production.

Belt conveyor: as a "link" connecting various links, it efficiently transfers materials between various equipment. It can be customized according to the actual needs of the production site and flexibly arranged between various equipment. It has the advantages of long conveying distance, large conveying capacity, and reliable operation, ensuring smooth material transmission and improving the automation and production efficiency of the entire production line.

Dust removal system

Including fans, motors, dust treatment and recovery systems, etc., used to collect and treat dust generated during the production process, reduce dust pollution to the environment, protect the health of workers, and at the same time realize dust recycling and reduce production costs.

Previous: SMP Crusher

Next: SMP Crusher

What are the complete equipment of sand and gravel production line?

What are the complete equipment of sand and gravel production line? What is the efficiency of the complete set of equipment for the sand and gravel production line?

What is the efficiency of the complete set of equipment for the sand and gravel production line? The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line What are the complete equipment of sand and gravel production line?

What are the complete equipment of sand and gravel production line? What is the efficiency of the complete set of equipment for the sand and gravel production line?

What is the efficiency of the complete set of equipment for the sand and gravel production line? The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs

The production capacity of a complete set of equipment for the sand and gravel production line is revealed: customized solutions to meet diverse needs Full analysis of basalt sand and gravel production line

Full analysis of basalt sand and gravel production line A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line