Flotation beneficiation production line combines feeding, crushing, ball milling, flotation and other functions, the whole production line's degree of automation, accuracy of ore powder, production performance has reached a high level, it is a high

Flotation beneficiation production line combines feeding, crushing, ball milling, flotation and other functions, the whole production line's degree of automation, accuracy of ore powder, production performance has reached a high level, it is a high-precision, energy-saving production line, which is widely used in the beneficiation of concentrates of various metal and non-metal ores, such as copper, nickel, iron, gold, fluorite and so on.

Production situation

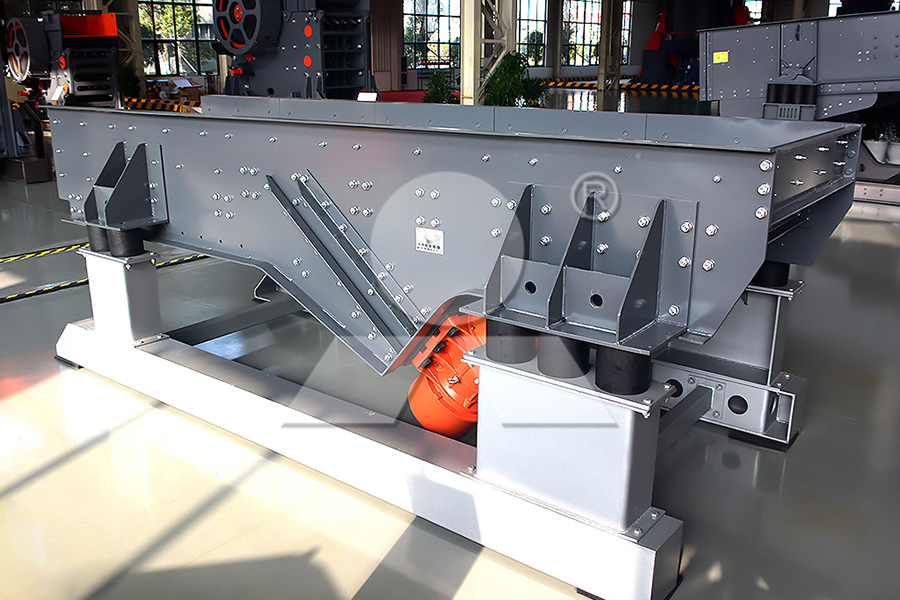

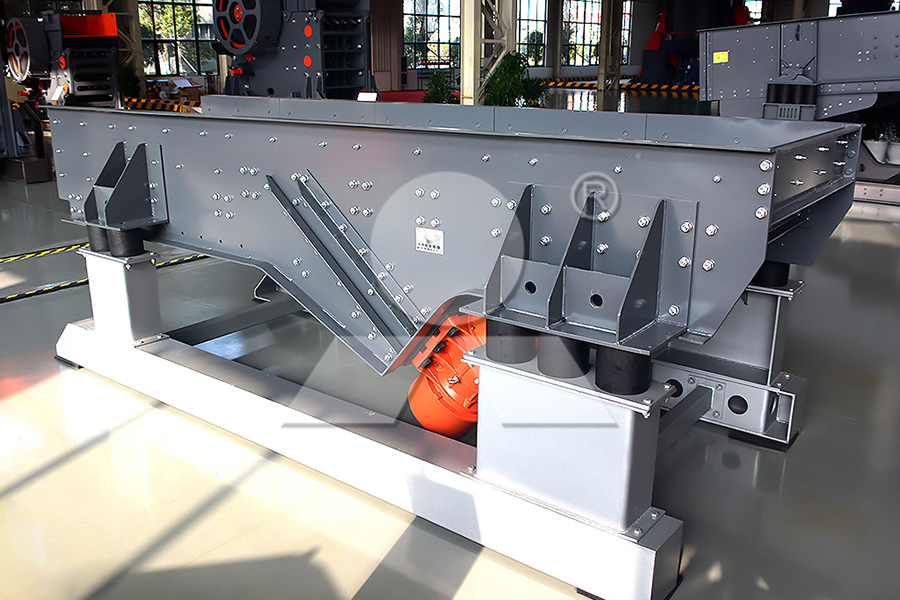

The mined fluorite is firstly fed into the jaw crusher by vibrating feeder evenly and quantitatively for rough crushing, and the roughly crushed fluorite is screened by vibrating screen, and the qualified ones are fed into the cone crusher for medium and fine crushing, and the ones that don't meet the requirements need to return to the jaw crusher for re-crushing, and the finely crushed mineral particles are fed into the flotation machine, and different drugs are added according to different mineral characteristics, so as to separate the desired minerals and other The drugs are added according to different mineral properties, so that the desired minerals can be separated from other substances. After the minerals are separated out, because they contain a lot of water, they have to be initially concentrated by the concentrator and then dried by the dryer to get dry minerals.

Customer Feedback

The flotation process production line configured by Liming Heavy Industry has been used for a long time, and we feel that the performance of the whole production line is very good, and it is very easy to control the fineness of the finished product, the flotation quality fraction and the pulp acidity and alkalinity. After the installation and commissioning of the equipment, the company's technical personnel also gave us a summary of some of the basic principles of operation of the flotation equipment, whenever we have a problem, it is always patiently for us to solve it, thank you very much, very happy and Liming Heavy Industry's cooperation!

Previous: SMP Crusher

Next: SMP Crusher

Flotation beneficiation production line combines feeding, crushing, ball milling, flotation and other functions, the whole production line's degree of automation, accuracy of ore powder, production performance has reached a high level, it is a high

Flotation beneficiation production line combines feeding, crushing, ball milling, flotation and other functions, the whole production line's degree of automation, accuracy of ore powder, production performance has reached a high level, it is a high-precision, energy-saving production line, which is widely used in the beneficiation of concentrates of various metal and non-metal ores, such as copper, nickel, iron, gold, fluorite and so on.

Production situation

The mined fluorite is firstly fed into the jaw crusher by vibrating feeder evenly and quantitatively for rough crushing, and the roughly crushed fluorite is screened by vibrating screen, and the qualified ones are fed into the cone crusher for medium and fine crushing, and the ones that don't meet the requirements need to return to the jaw crusher for re-crushing, and the finely crushed mineral particles are fed into the flotation machine, and different drugs are added according to different mineral characteristics, so as to separate the desired minerals and other The drugs are added according to different mineral properties, so that the desired minerals can be separated from other substances. After the minerals are separated out, because they contain a lot of water, they have to be initially concentrated by the concentrator and then dried by the dryer to get dry minerals.

Customer Feedback

The flotation process production line configured by Liming Heavy Industry has been used for a long time, and we feel that the performance of the whole production line is very good, and it is very easy to control the fineness of the finished product, the flotation quality fraction and the pulp acidity and alkalinity. After the installation and commissioning of the equipment, the company's technical personnel also gave us a summary of some of the basic principles of operation of the flotation equipment, whenever we have a problem, it is always patiently for us to solve it, thank you very much, very happy and Liming Heavy Industry's cooperation!

Previous: SMP Crusher

Next: SMP Crusher

Henan Jiaozuo Iron Ore Magnetic Separation Production Line

Henan Jiaozuo Iron Ore Magnetic Separation Production Line Hunan Manganese Ore Beneficiation Production Line

Hunan Manganese Ore Beneficiation Production Line Guangxi manganese ore magnetic separation process production line

Guangxi manganese ore magnetic separation process production line Liaoning Anshan large scale iron ore magnetic separation process production line

Liaoning Anshan large scale iron ore magnetic separation process production line Yunnan copper ore flotation process production line

Yunnan copper ore flotation process production line Henan Jiaozuo Iron Ore Magnetic Separation Production Line

Henan Jiaozuo Iron Ore Magnetic Separation Production Line Hunan Manganese Ore Beneficiation Production Line

Hunan Manganese Ore Beneficiation Production Line Guangxi manganese ore magnetic separation process production line

Guangxi manganese ore magnetic separation process production line Liaoning Anshan large scale iron ore magnetic separation process production line

Liaoning Anshan large scale iron ore magnetic separation process production line Yunnan copper ore flotation process production line

Yunnan copper ore flotation process production line