The stone crusher production line is flexibly matched with jaw breaking, cone breaking, counterattack breaking and other equipment to adapt to different stone materials and output requirements. From the PE series of 200 tons per hour to the high-perfor

The stone crusher production line is flexibly matched with jaw breaking, cone breaking, counterattack breaking and other equipment to adapt to different stone materials and output requirements. From the PE series of 200 tons per hour to the high-performance C6X jaw breaking, the hard material is cone breaking, and the heavy grain type is counterattack breaking. The price of the whole set of configuration ranges from hundreds of thousands to tens of millions."

The whole set of equipment of stone crusher includes coarse crushing equipment, medium crushing equipment, fine crushing equipment, feeder, screening machine, belt conveyor, etc. Users can freely match the equipment and models according to their own stone size, stone properties and finished product requirements.

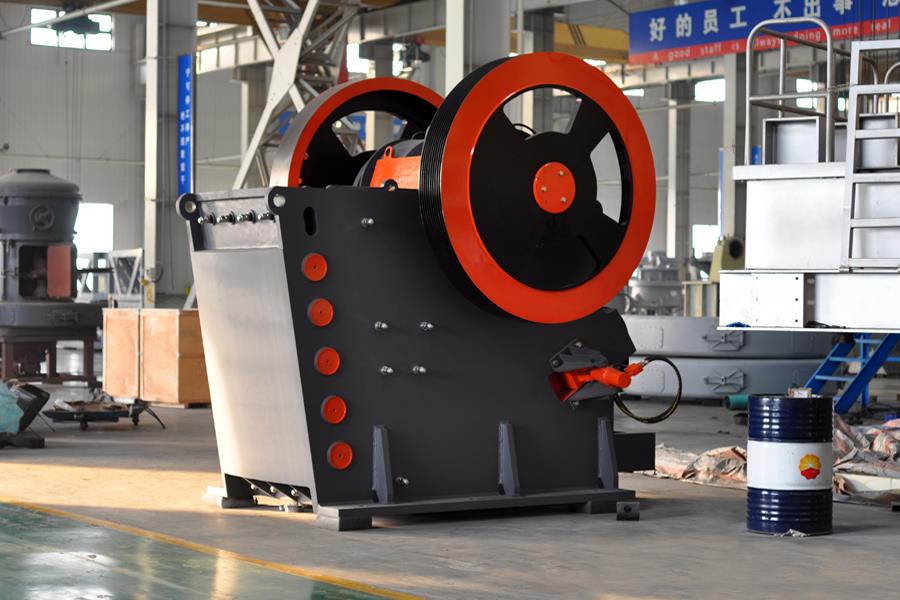

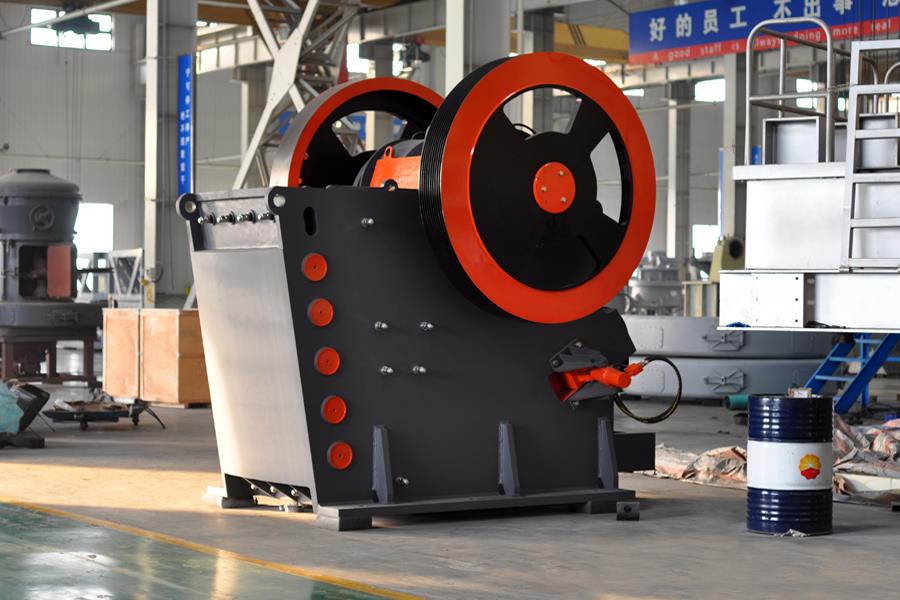

The coarse crushing equipment generally uses a jaw crusher, which has stable performance and powerful functions. Whether it is soft or hard materials, it can be crushed well. There are also many models of jaw crushers with 200 tons per hour, including basic PE series, such as PE750 × 1060, medium PEW series, such as PEW760, and high-performance C6X jaw crushers, such as C6X80.

Crushing equipment commonly used in the cone crusher, impact crusher, they have their own advantages, crushing equipment models are PF1214 impact crusher, HPT200 multi-cylinder hydraulic cone crusher and so on. If you want the finished product to have a good grain shape, recommend the impact crusher, the finished product has less needle piece content, good grain shape, and the machine price is relatively cheap. If your stone is hard, recommend a cone crusher, its vulnerable parts are wear-resistant, and the cost of crushed stone hard materials is lower.

The stone crusher production line can be determined according to the production requirements, processing materials, daily output, discharge particle size and finished product use. In the face of different production conditions of customers in different regions, the price of the stone crusher production line with a output of 200 tons may vary from one hundred thousand to another, with the price of the whole stone crusher ranging from hundreds of thousands to millions or even tens of millions. The cost of configuring the 1 production line includes equipment cost, labor cost, installation cost, installation cost, etc, therefore, there are no specific figures for the price of the gravel production line of the specific stone plant.

Previous: SMP Crusher

Next: SMP Crusher

The stone crusher production line is flexibly matched with jaw breaking, cone breaking, counterattack breaking and other equipment to adapt to different stone materials and output requirements. From the PE series of 200 tons per hour to the high-perfor

The stone crusher production line is flexibly matched with jaw breaking, cone breaking, counterattack breaking and other equipment to adapt to different stone materials and output requirements. From the PE series of 200 tons per hour to the high-performance C6X jaw breaking, the hard material is cone breaking, and the heavy grain type is counterattack breaking. The price of the whole set of configuration ranges from hundreds of thousands to tens of millions."

The whole set of equipment of stone crusher includes coarse crushing equipment, medium crushing equipment, fine crushing equipment, feeder, screening machine, belt conveyor, etc. Users can freely match the equipment and models according to their own stone size, stone properties and finished product requirements.

The coarse crushing equipment generally uses a jaw crusher, which has stable performance and powerful functions. Whether it is soft or hard materials, it can be crushed well. There are also many models of jaw crushers with 200 tons per hour, including basic PE series, such as PE750 × 1060, medium PEW series, such as PEW760, and high-performance C6X jaw crushers, such as C6X80.

Crushing equipment commonly used in the cone crusher, impact crusher, they have their own advantages, crushing equipment models are PF1214 impact crusher, HPT200 multi-cylinder hydraulic cone crusher and so on. If you want the finished product to have a good grain shape, recommend the impact crusher, the finished product has less needle piece content, good grain shape, and the machine price is relatively cheap. If your stone is hard, recommend a cone crusher, its vulnerable parts are wear-resistant, and the cost of crushed stone hard materials is lower.

The stone crusher production line can be determined according to the production requirements, processing materials, daily output, discharge particle size and finished product use. In the face of different production conditions of customers in different regions, the price of the stone crusher production line with a output of 200 tons may vary from one hundred thousand to another, with the price of the whole stone crusher ranging from hundreds of thousands to millions or even tens of millions. The cost of configuring the 1 production line includes equipment cost, labor cost, installation cost, installation cost, etc, therefore, there are no specific figures for the price of the gravel production line of the specific stone plant.

Previous: SMP Crusher

Next: SMP Crusher

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation The difference between tailings sand and machine-made sand and the application of tailings sand making equipment

The difference between tailings sand and machine-made sand and the application of tailings sand making equipment How to choose the equipment suitable for basalt sand making

How to choose the equipment suitable for basalt sand making How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation

How to maintain a large cone crusher with a daily output of 10000 tons after long-term operation The difference between tailings sand and machine-made sand and the application of tailings sand making equipment

The difference between tailings sand and machine-made sand and the application of tailings sand making equipment How to choose the equipment suitable for basalt sand making

How to choose the equipment suitable for basalt sand making How to choose the equipment suitable for granite sand making

How to choose the equipment suitable for granite sand making How much is a full set of calcite equipment? What equipment is needed

How much is a full set of calcite equipment? What equipment is needed