Limestone is a good multi-purpose stone material, which is widely used in chemical industry, metallurgy, building materials, construction, environmental protection, agriculture, food, etc. A limestone crushing production line has high production effici

Limestone is a good multi-purpose stone material, which is widely used in chemical industry, metallurgy, building materials, construction, environmental protection, agriculture, food, etc. A limestone crushing production line has high production efficiency, large output and good quality of finished aggregate. So how to configure the plan?

Click to consult to understand the construction plan of limestone production line

1. Configuration of limestone crushing production line

1. Configuration for processing high hardness limestone (69 jaw crusher + 1300 cone crusher)

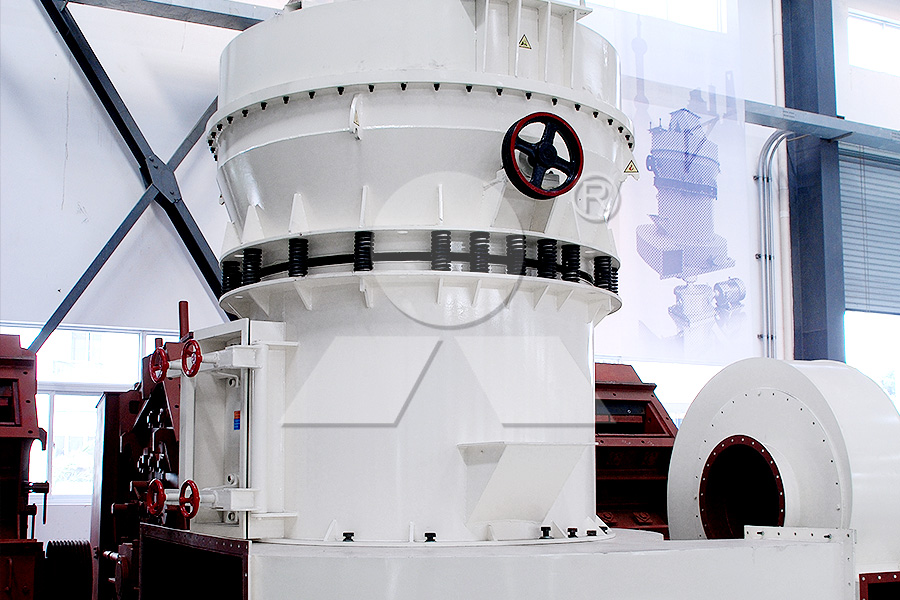

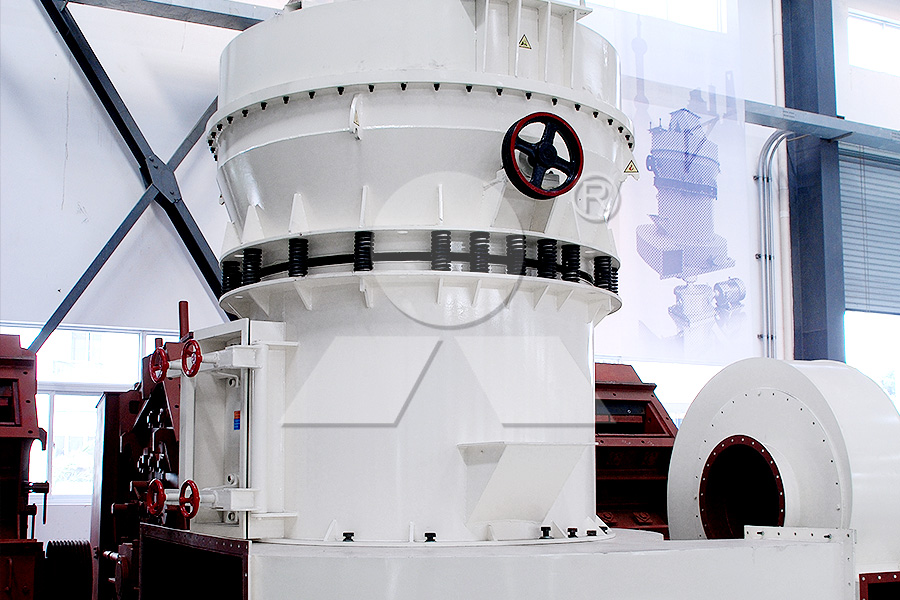

With ZSW380*95 vibrating feeder and 1854 vibrating screen, the main equipment 69 jaw crusher and 1300 cone crusher are the core. 69 jaw crusher is a commonly used equipment for coarse crushing, with an output of about 100 tons per hour, simple structure, easy maintenance, and can easily meet the needs of coarse crushing; 1300 cone crusher is a composite type with a large crushing ratio, large processing capacity and long life.

2. Configuration for processing softer limestone (69 jaw crusher + PF1214 impact crusher)

For limestone with lower hardness, a production line with 69 jaw crusher and PF1214 impact crusher can be selected. The former is responsible for coarse crushing, while the latter is for medium and fine crushing, ensuring that the discharge particle size is controllable and the particle shape is good. This solution flexibly configures auxiliary equipment according to site requirements, and customer feedback is good. This production line has low investment cost and is economical. At the same time, it achieves excellent crushing effect with strong impact force to meet production needs.

3. Mobile configuration limestone crushing production line

Unlike fixed crushing equipment such as jaw crusher, cone crusher, and impact crusher, the limestone mobile crushing station adopts an integrated vehicle-mounted system, which realizes the flexible movement of the equipment and can be driven directly to the customer's production site.

Previous: SMP Crusher

Next: SMP Crusher

Limestone is a good multi-purpose stone material, which is widely used in chemical industry, metallurgy, building materials, construction, environmental protection, agriculture, food, etc. A limestone crushing production line has high production effici

Limestone is a good multi-purpose stone material, which is widely used in chemical industry, metallurgy, building materials, construction, environmental protection, agriculture, food, etc. A limestone crushing production line has high production efficiency, large output and good quality of finished aggregate. So how to configure the plan?

Click to consult to understand the construction plan of limestone production line

1. Configuration of limestone crushing production line

1. Configuration for processing high hardness limestone (69 jaw crusher + 1300 cone crusher)

With ZSW380*95 vibrating feeder and 1854 vibrating screen, the main equipment 69 jaw crusher and 1300 cone crusher are the core. 69 jaw crusher is a commonly used equipment for coarse crushing, with an output of about 100 tons per hour, simple structure, easy maintenance, and can easily meet the needs of coarse crushing; 1300 cone crusher is a composite type with a large crushing ratio, large processing capacity and long life.

2. Configuration for processing softer limestone (69 jaw crusher + PF1214 impact crusher)

For limestone with lower hardness, a production line with 69 jaw crusher and PF1214 impact crusher can be selected. The former is responsible for coarse crushing, while the latter is for medium and fine crushing, ensuring that the discharge particle size is controllable and the particle shape is good. This solution flexibly configures auxiliary equipment according to site requirements, and customer feedback is good. This production line has low investment cost and is economical. At the same time, it achieves excellent crushing effect with strong impact force to meet production needs.

3. Mobile configuration limestone crushing production line

Unlike fixed crushing equipment such as jaw crusher, cone crusher, and impact crusher, the limestone mobile crushing station adopts an integrated vehicle-mounted system, which realizes the flexible movement of the equipment and can be driven directly to the customer's production site.

Previous: SMP Crusher

Next: SMP Crusher

How to choose a suitable sand making machine? What factors should be paid attention to when purchasing a sand making machine

How to choose a suitable sand making machine? What factors should be paid attention to when purchasing a sand making machine How to build a high-quality basalt sand making equipment production line

How to build a high-quality basalt sand making equipment production line What equipment is used to crush granite into sand

What equipment is used to crush granite into sand Which equipment to use for crushing iron ore

Which equipment to use for crushing iron ore What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore? How to choose a suitable sand making machine? What factors should be paid attention to when purchasing a sand making machine

How to choose a suitable sand making machine? What factors should be paid attention to when purchasing a sand making machine How to build a high-quality basalt sand making equipment production line

How to build a high-quality basalt sand making equipment production line What equipment is used to crush granite into sand

What equipment is used to crush granite into sand Which equipment to use for crushing iron ore

Which equipment to use for crushing iron ore What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?

What is the process flow for processing lead-zinc ore? Which equipment should be used for crushing lead-zinc ore?