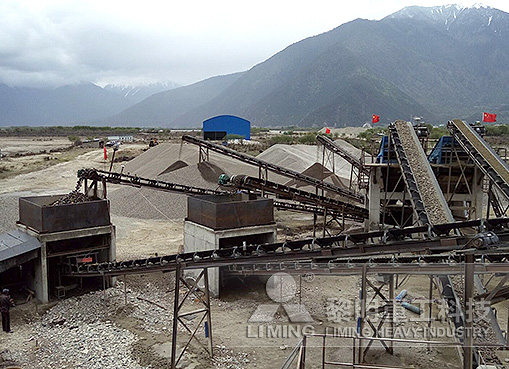

The pebble sand production line in Linzhi County, Tibet is located in Bujiu Township, Bayi District, Linzhi City, near the 19 th Bureau of China Railway, 5 km from the Linzhi Railway Station under construction, and the finished material is used for rai

The pebble sand production line in Linzhi County, Tibet is located in Bujiu Township, Bayi District, Linzhi City, near the 19 th Bureau of China Railway, 5 km from the Linzhi Railway Station under construction, and the finished material is used for railway construction.

Processing material river pebbles, yield 80 square / hour, feed particle size 0-300mm, discharge particle size, 0-5mm, 5-10mm, 10-20mm, 20-30mm

The raw material is sent from the forklift to the raw material warehouse, and the feeder is evenly sent to the PE500 × 750 jaw crusher. The jaw crusher and the cone crusher share a common belt. The produced material is sent from the main belt to the 3YZS1860 vibrating screen. The raw sand is directly separated, and the large material is returned to the HST100 single-cylinder hydraulic cone crusher for reprocessing. The sand less than 3cm is processed by the VSI9526 sand making machine, and the material is screened by the 4YZS1848 vibrating screen. Four finished materials are produced.

The sand making scheme has high crushing efficiency, low production cost, excellent finished product particle shape and reasonable grade matching, which meets the requirements of railway construction standards

Previous: SMP Crusher

Next: SMP Crusher

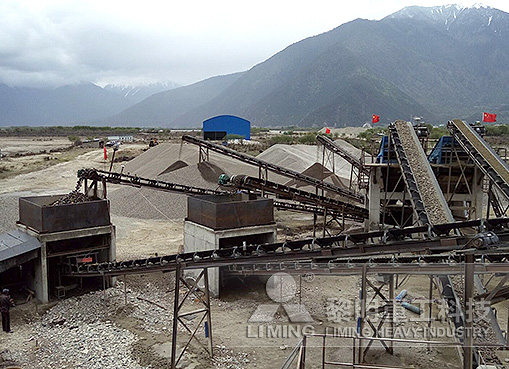

The pebble sand production line in Linzhi County, Tibet is located in Bujiu Township, Bayi District, Linzhi City, near the 19 th Bureau of China Railway, 5 km from the Linzhi Railway Station under construction, and the finished material is used for rai

The pebble sand production line in Linzhi County, Tibet is located in Bujiu Township, Bayi District, Linzhi City, near the 19 th Bureau of China Railway, 5 km from the Linzhi Railway Station under construction, and the finished material is used for railway construction.

Processing material river pebbles, yield 80 square / hour, feed particle size 0-300mm, discharge particle size, 0-5mm, 5-10mm, 10-20mm, 20-30mm

The raw material is sent from the forklift to the raw material warehouse, and the feeder is evenly sent to the PE500 × 750 jaw crusher. The jaw crusher and the cone crusher share a common belt. The produced material is sent from the main belt to the 3YZS1860 vibrating screen. The raw sand is directly separated, and the large material is returned to the HST100 single-cylinder hydraulic cone crusher for reprocessing. The sand less than 3cm is processed by the VSI9526 sand making machine, and the material is screened by the 4YZS1848 vibrating screen. Four finished materials are produced.

The sand making scheme has high crushing efficiency, low production cost, excellent finished product particle shape and reasonable grade matching, which meets the requirements of railway construction standards

Previous: SMP Crusher

Next: SMP Crusher