When purchasing crushing equipment, it is necessary to comprehensively consider production capacity, raw material characteristics, finished product particle size and site conditions. High-quality suppliers should have a professional team, a complete pr

When purchasing crushing equipment, it is necessary to comprehensively consider production capacity, raw material characteristics, finished product particle size and site conditions. High-quality suppliers should have a professional team, a complete production system, reliable services and mature cases. With advanced technology, intelligent control and environmentally friendly design, Shibang Industry provides efficient and reliable crushing solutions for global customers.

When purchasing crushing equipment, how to choose high-quality brands and suppliers is the most concerned issue for customers. As a professional equipment manufacturer in the field of mining crushing, Shibang Industrial Technology Group has provided high-quality crushing solutions to many customers with many years of industry experience.

Learn how to choose crushing and sand making equipment Click to consult

1. Key points for purchasing crushing equipment

Capacity matching

It is recommended to select a suitable production capacity range according to the actual needs of the production line. The processing capacity of common equipment ranges from a few tons to thousands of tons per hour, and it is necessary to accurately calculate the material characteristics and production cycle to determine the equipment specifications.

Raw material characteristics analysis

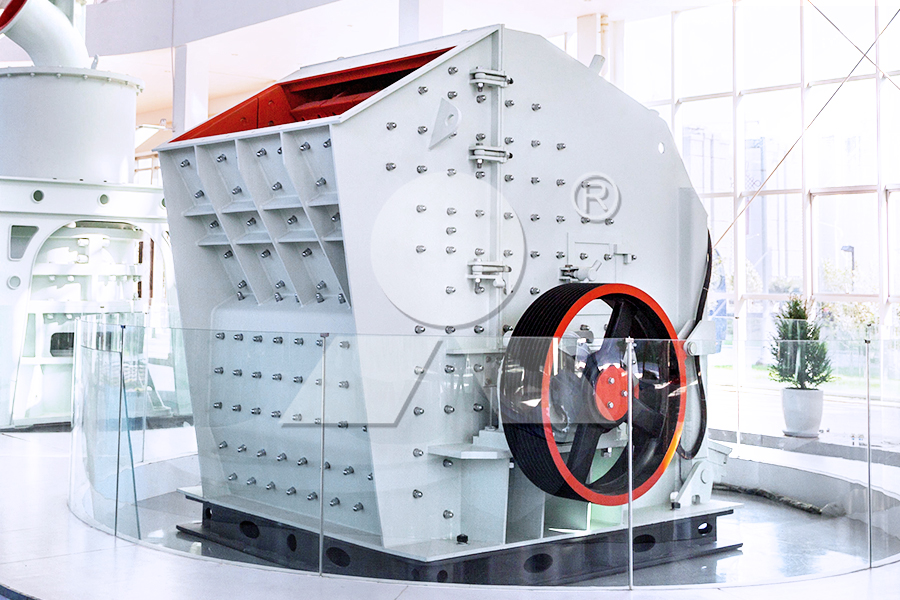

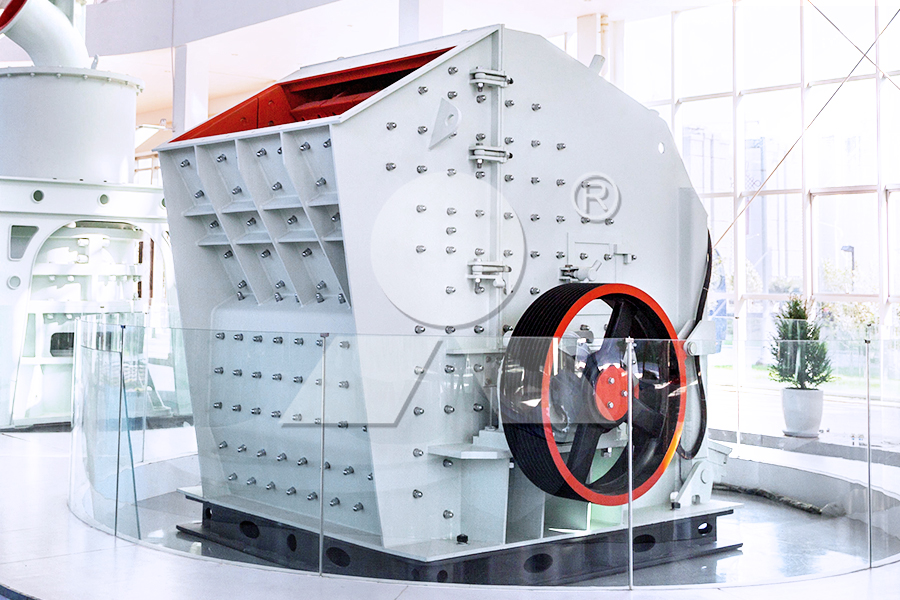

Different mineral hardness, water content and other characteristics will affect the selection of equipment. For example, it is recommended to use a jaw crusher for primary crushing of hard rocks such as granite, while an impact crusher can be used for medium-hardness materials such as limestone.

Finished product particle size requirements

Determine the required crushing ratio according to the purpose of the final product. When it is necessary to produce stones of various specifications, consider configuring a multi-stage crushing and screening system.

Site condition assessment

Equipment installation needs to fully consider factors such as site space, power configuration, and environmental protection requirements. Mobile crushing stations are suitable for working conditions with limited sites.

2. Selection criteria for high-quality manufacturers

Professional technical team

Having a team of senior engineers to provide process flow design and equipment selection suggestions is an important consideration. Shibang Group is equipped with more than 100 professional R&D personnel to customize the best solutions for customers.

Perfect production system

The complete manufacturing chain from casting, machining to assembly and testing ensures the quality of equipment. We have a modern production base, and key components are made of high-quality alloy steel.

Reliable service network

The perfect after-sales service system includes equipment installation guidance, operation training, regular maintenance, etc. Shibang has more than 30 service outlets across the country to provide fast-response technical support.

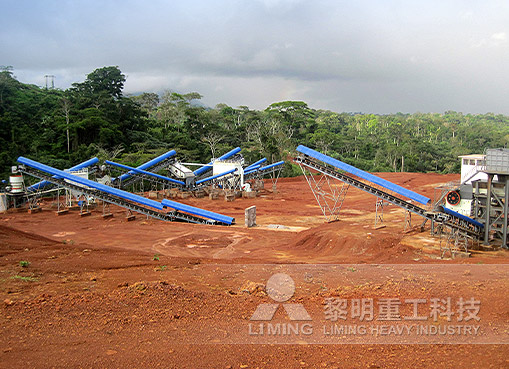

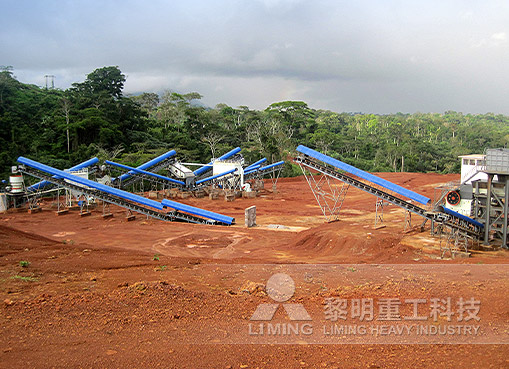

Mature case experience

It is more valuable to examine the successful cases of manufacturers in similar projects. We have provided reliable equipment and services to customers in hundreds of countries and regions around the world.

3. Features of Shibang Crushing Equipment

Advanced technical design

The equipment structure is optimized by computer-aided design, and the reliability of key components is ensured by finite element analysis, which greatly improves the service life of the equipment.

Intelligent control system

The PLC automatic control system can be optionally equipped to realize real-time monitoring of operating parameters and fault warning, and improve production management efficiency.

Low energy consumption and high efficiency

By optimizing the crushing cavity type and motion parameters, the energy consumption per unit output is reduced compared with traditional equipment.

Good environmental performance

Multiple dust and noise reduction measures are adopted, and a pulse dust removal system is configured to meet increasingly stringent environmental protection requirements.

Choosing a professional and reliable crushing equipment supplier according to the above standards can ensure the long-term and stable operation of the production line. Shibang Industry is willing to provide you with technical consulting services in the field of crushing and screening to help you choose the most suitable production solution.

Previous: SMP Crusher

Next: SMP Crusher

When purchasing crushing equipment, it is necessary to comprehensively consider production capacity, raw material characteristics, finished product particle size and site conditions. High-quality suppliers should have a professional team, a complete pr

When purchasing crushing equipment, it is necessary to comprehensively consider production capacity, raw material characteristics, finished product particle size and site conditions. High-quality suppliers should have a professional team, a complete production system, reliable services and mature cases. With advanced technology, intelligent control and environmentally friendly design, Shibang Industry provides efficient and reliable crushing solutions for global customers.

When purchasing crushing equipment, how to choose high-quality brands and suppliers is the most concerned issue for customers. As a professional equipment manufacturer in the field of mining crushing, Shibang Industrial Technology Group has provided high-quality crushing solutions to many customers with many years of industry experience.

Learn how to choose crushing and sand making equipment Click to consult

1. Key points for purchasing crushing equipment

Capacity matching

It is recommended to select a suitable production capacity range according to the actual needs of the production line. The processing capacity of common equipment ranges from a few tons to thousands of tons per hour, and it is necessary to accurately calculate the material characteristics and production cycle to determine the equipment specifications.

Raw material characteristics analysis

Different mineral hardness, water content and other characteristics will affect the selection of equipment. For example, it is recommended to use a jaw crusher for primary crushing of hard rocks such as granite, while an impact crusher can be used for medium-hardness materials such as limestone.

Finished product particle size requirements

Determine the required crushing ratio according to the purpose of the final product. When it is necessary to produce stones of various specifications, consider configuring a multi-stage crushing and screening system.

Site condition assessment

Equipment installation needs to fully consider factors such as site space, power configuration, and environmental protection requirements. Mobile crushing stations are suitable for working conditions with limited sites.

2. Selection criteria for high-quality manufacturers

Professional technical team

Having a team of senior engineers to provide process flow design and equipment selection suggestions is an important consideration. Shibang Group is equipped with more than 100 professional R&D personnel to customize the best solutions for customers.

Perfect production system

The complete manufacturing chain from casting, machining to assembly and testing ensures the quality of equipment. We have a modern production base, and key components are made of high-quality alloy steel.

Reliable service network

The perfect after-sales service system includes equipment installation guidance, operation training, regular maintenance, etc. Shibang has more than 30 service outlets across the country to provide fast-response technical support.

Mature case experience

It is more valuable to examine the successful cases of manufacturers in similar projects. We have provided reliable equipment and services to customers in hundreds of countries and regions around the world.

3. Features of Shibang Crushing Equipment

Advanced technical design

The equipment structure is optimized by computer-aided design, and the reliability of key components is ensured by finite element analysis, which greatly improves the service life of the equipment.

Intelligent control system

The PLC automatic control system can be optionally equipped to realize real-time monitoring of operating parameters and fault warning, and improve production management efficiency.

Low energy consumption and high efficiency

By optimizing the crushing cavity type and motion parameters, the energy consumption per unit output is reduced compared with traditional equipment.

Good environmental performance

Multiple dust and noise reduction measures are adopted, and a pulse dust removal system is configured to meet increasingly stringent environmental protection requirements.

Choosing a professional and reliable crushing equipment supplier according to the above standards can ensure the long-term and stable operation of the production line. Shibang Industry is willing to provide you with technical consulting services in the field of crushing and screening to help you choose the most suitable production solution.

Previous: SMP Crusher

Next: SMP Crusher

How to configure a 400 tons per hour sand and gravel production line

How to configure a 400 tons per hour sand and gravel production line How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks How to configure a 400 tons per hour sand and gravel production line

How to configure a 400 tons per hour sand and gravel production line How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line How to crush aluminum ore and what equipment is needed

How to crush aluminum ore and what equipment is needed Professional crusher manufacturers analyze the advantages of dry sand making technology

Professional crusher manufacturers analyze the advantages of dry sand making technology Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks