By upgrading C6X jaw crusher and HST cone crusher, the Liming technical team significantly improved the crushing efficiency of Inner Mongolia magnetite, greatly improved the matching degree of equipment stability and production capacity, and the custom

By upgrading C6X jaw crusher and HST cone crusher, the Liming technical team significantly improved the crushing efficiency of Inner Mongolia magnetite, greatly improved the matching degree of equipment stability and production capacity, and the customer cooperated several times to build a modern production line.

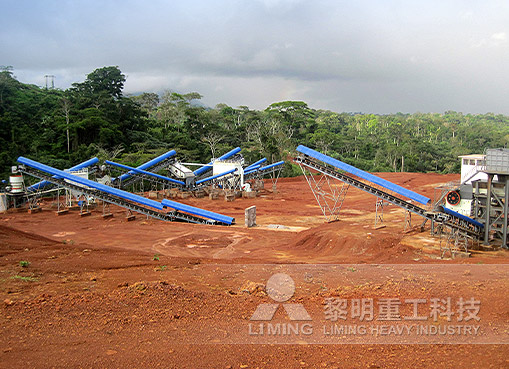

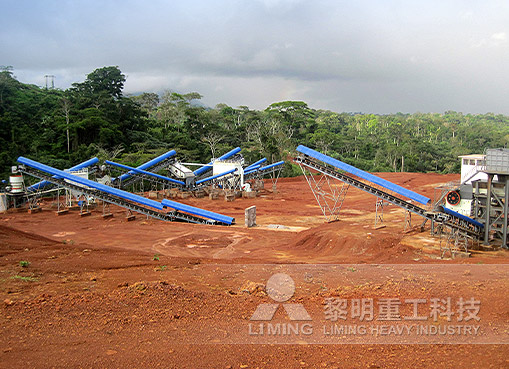

In a large magnetite project in Inner Mongolia, the customer's original crushing production line had many areas that needed improvement. Among them, the lack of coordination between the three crushing processes led to low overall efficiency, and there was a certain gap between the equipment operation stability and the designed capacity. The original PE series jaw crusher and cone crusher equipment not only had a high failure rate, but also the after-sales support response speed failed to meet the requirements of continuous production.

Click to consult to learn about the construction plan of the metal ore crushing production line

In response to this situation, the project party specially invited the Liming technical team to conduct professional evaluation and solution design. Through in-depth research on the on-site working conditions, Liming engineers proposed a systematic transformation plan:

1. Upgrade of the coarse crushing process The C6X series jaw crusher was used to replace the traditional PE model. Its unique V-shaped crushing chamber design effectively improved the material blockage. Practical data shows that this improvement has improved the working efficiency of the coarse crushing stage.

2. Optimization of the medium crushing process. The HST single-cylinder hydraulic cone crusher was configured to replace the original equipment. By increasing the crushing ratio of the medium crushing section, the load of the subsequent fine crushing and screening system was significantly reduced. This process adjustment makes the crushing ratio distribution of the entire production line more scientific and the connection of each process more smooth.

The performance of the production line after the technical transformation exceeded expectations, mainly reflected in:

1. The stability of equipment operation has been greatly improved

2. The matching degree of production capacity in each link has been significantly improved

3. The overall production efficiency has been effectively improved

Based on this successful cooperation experience, the customer has subsequently carried out in-depth cooperation with Liming Group for many times and successively built a number of modern iron ore processing production lines. Through continuous technical exchanges and innovative practices, the two parties have jointly promoted the progress of local mineral processing technology.

The successful implementation of this Inner Mongolia project not only solved the actual production problems faced by customers, but also demonstrated the technical strength and service level of the Liming team in the field of mineral processing. In the future, we will continue to deepen technological innovation and work with more partners to promote high-quality development of the industry.

Previous: SMP Crusher

Next: SMP Crusher

By upgrading C6X jaw crusher and HST cone crusher, the Liming technical team significantly improved the crushing efficiency of Inner Mongolia magnetite, greatly improved the matching degree of equipment stability and production capacity, and the custom

By upgrading C6X jaw crusher and HST cone crusher, the Liming technical team significantly improved the crushing efficiency of Inner Mongolia magnetite, greatly improved the matching degree of equipment stability and production capacity, and the customer cooperated several times to build a modern production line.

In a large magnetite project in Inner Mongolia, the customer's original crushing production line had many areas that needed improvement. Among them, the lack of coordination between the three crushing processes led to low overall efficiency, and there was a certain gap between the equipment operation stability and the designed capacity. The original PE series jaw crusher and cone crusher equipment not only had a high failure rate, but also the after-sales support response speed failed to meet the requirements of continuous production.

Click to consult to learn about the construction plan of the metal ore crushing production line

In response to this situation, the project party specially invited the Liming technical team to conduct professional evaluation and solution design. Through in-depth research on the on-site working conditions, Liming engineers proposed a systematic transformation plan:

1. Upgrade of the coarse crushing process The C6X series jaw crusher was used to replace the traditional PE model. Its unique V-shaped crushing chamber design effectively improved the material blockage. Practical data shows that this improvement has improved the working efficiency of the coarse crushing stage.

2. Optimization of the medium crushing process. The HST single-cylinder hydraulic cone crusher was configured to replace the original equipment. By increasing the crushing ratio of the medium crushing section, the load of the subsequent fine crushing and screening system was significantly reduced. This process adjustment makes the crushing ratio distribution of the entire production line more scientific and the connection of each process more smooth.

The performance of the production line after the technical transformation exceeded expectations, mainly reflected in:

1. The stability of equipment operation has been greatly improved

2. The matching degree of production capacity in each link has been significantly improved

3. The overall production efficiency has been effectively improved

Based on this successful cooperation experience, the customer has subsequently carried out in-depth cooperation with Liming Group for many times and successively built a number of modern iron ore processing production lines. Through continuous technical exchanges and innovative practices, the two parties have jointly promoted the progress of local mineral processing technology.

The successful implementation of this Inner Mongolia project not only solved the actual production problems faced by customers, but also demonstrated the technical strength and service level of the Liming team in the field of mineral processing. In the future, we will continue to deepen technological innovation and work with more partners to promote high-quality development of the industry.

Previous: SMP Crusher

Next: SMP Crusher

How much does a set of sand making equipment cost?

How much does a set of sand making equipment cost? Limings 1,000-ton-per-hour limestone crushing production line Helping efficient use of resources

Limings 1,000-ton-per-hour limestone crushing production line Helping efficient use of resources Which brand of crusher is good? How to choose the manufacturer

Which brand of crusher is good? How to choose the manufacturer How to configure a 400 tons per hour sand and gravel production line

How to configure a 400 tons per hour sand and gravel production line How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line How much does a set of sand making equipment cost?

How much does a set of sand making equipment cost? Limings 1,000-ton-per-hour limestone crushing production line Helping efficient use of resources

Limings 1,000-ton-per-hour limestone crushing production line Helping efficient use of resources Which brand of crusher is good? How to choose the manufacturer

Which brand of crusher is good? How to choose the manufacturer How to configure a 400 tons per hour sand and gravel production line

How to configure a 400 tons per hour sand and gravel production line How to choose equipment for a 500 ton/hour granite production line

How to choose equipment for a 500 ton/hour granite production line